Jacket structure of flame-retardant cable

A flame-retardant cable and sheath technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of harsh working conditions, complicated environmental conditions, personal casualties, etc., and achieve the effects of avoiding underground accidents, safe and reliable use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

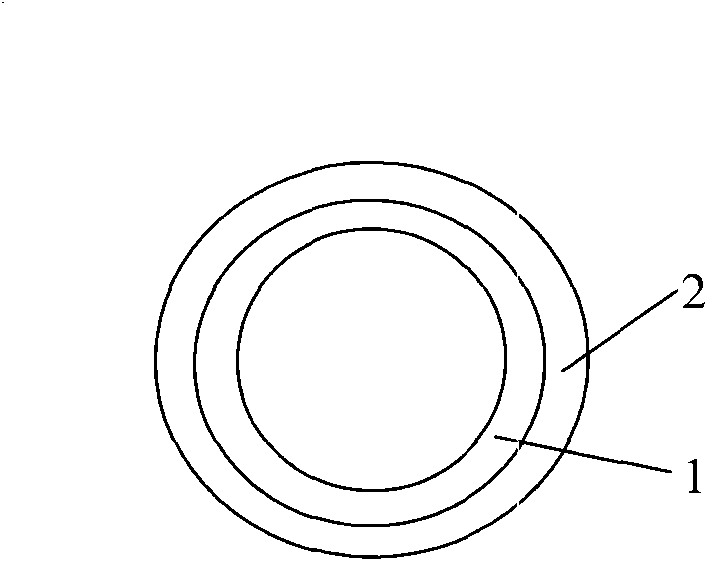

[0018] see figure 1 As shown, the sheath structure of the flame-retardant cable of the present invention includes an inner sheath 1 and an outer sheath 2 , and the outer sheath 2 is sleeved on the outer surface of the inner sheath 1 .

[0019] In a specific embodiment of the present invention, the outer sheath 2 is slidably sleeved on the outer surface of the inner sheath 1 .

[0020] Preferably, the inner sheath 1 and the outer sheath 2 are selected from a flame-retardant chlorinated polyethylene rubber sheath, a flame-retardant neoprene rubber sheath or a flame-retardant chlorosulfonated polyethylene rubber sheath.

[0021] In a specific embodiment of the present invention, the flame-retardant chlorinated polyethylene rubber sheath adopts a flame-retardant chlorinated polyethylene rubber with an oxygen index above 35.

[0022] In a specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com