Cage-type diphenyl sulfone-based oligomeric silsesquioxane and preparation method for same

A technology of polydiphenylsulfone and sesquioxane, applied in the field of nanomaterials, can solve problems such as poor solubility, and achieve mild and stable reaction conditions, good repeatability, and improved dielectric effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

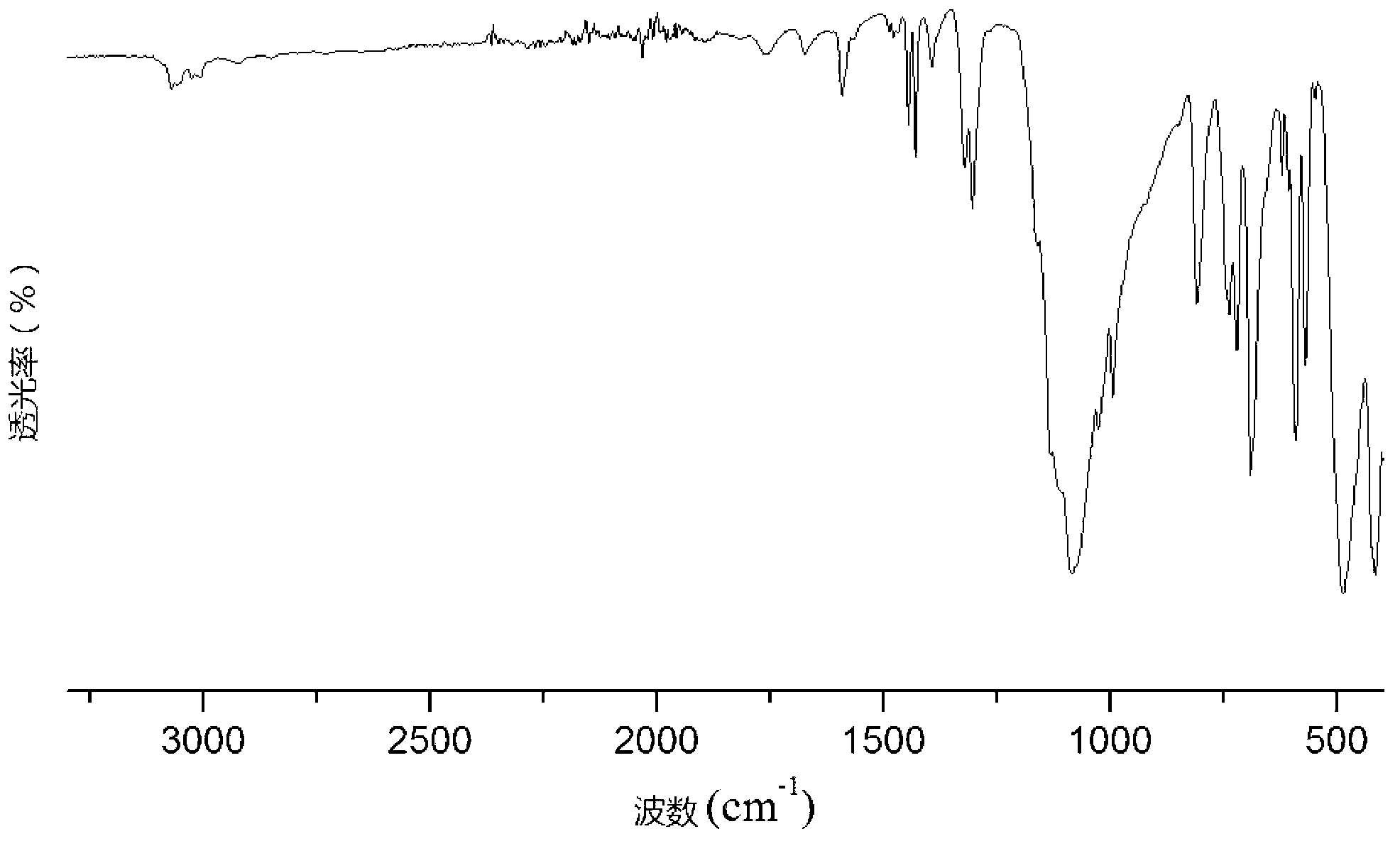

Embodiment 1

[0031] 1) Add 3.70g of cage-type octaphenylsilsesquioxane and 15ml of chloroform into a 100ml three-neck flask equipped with a reflux condenser, constant pressure dropping funnel, temperature control device, argon protection and magnetic stirring, Stir, the temperature is 60°C, add 3.81g of aluminum trichloride, then dropwise add 5.29g of benzenesulfonyl chloride, and react for 72 hours after the dropwise addition to obtain a reaction solution;

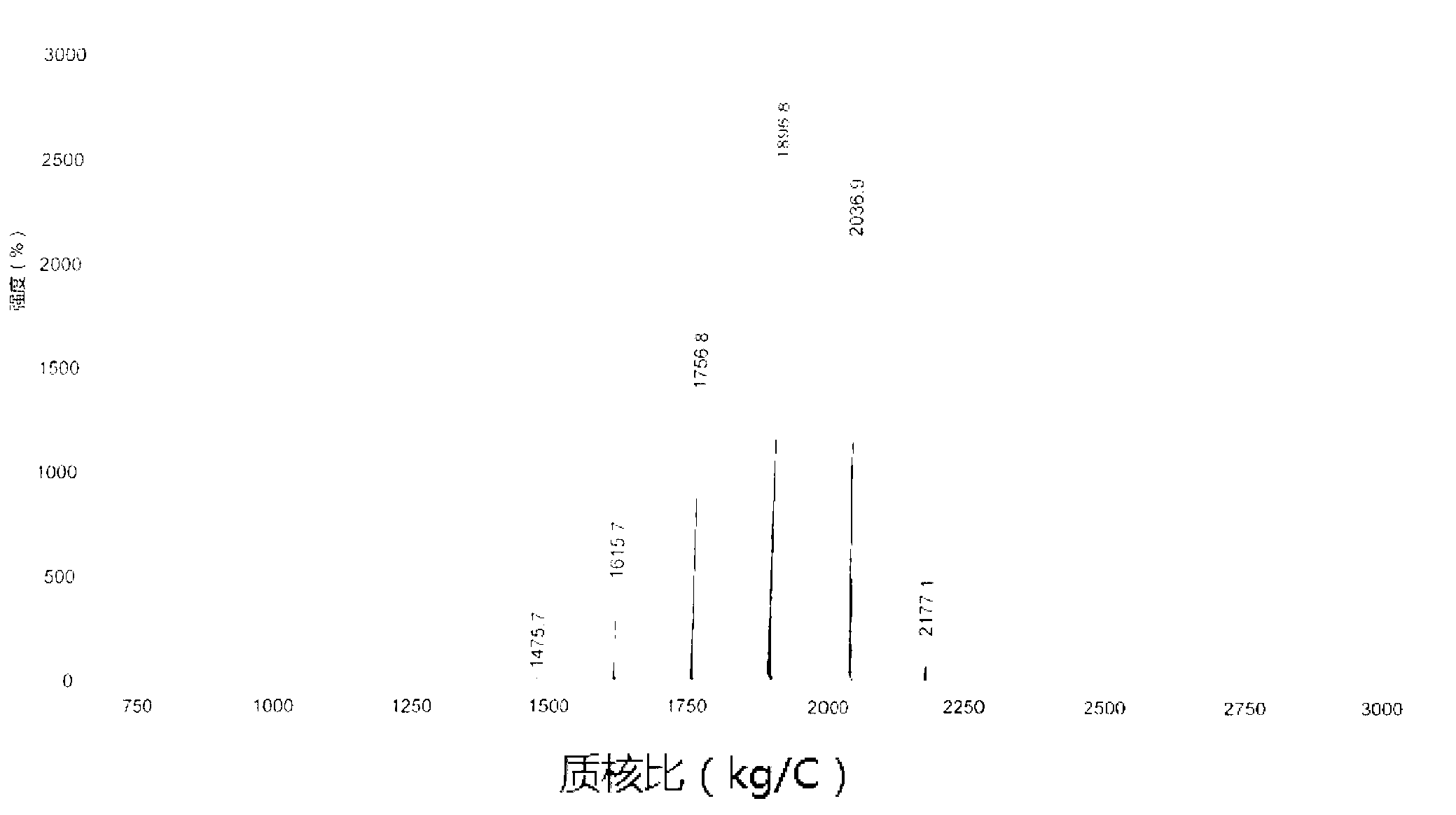

[0032] 2) Filter the reaction solution obtained in step 1), place the filtrate in a conical separatory funnel, wash it 3 times with a mixture of 200ml hydrochloric acid and ice water (the volume ratio of hydrochloric acid and ice water is 1:1), and then The organic layer was added into 500ml of n-hexane to precipitate a precipitate, which was dried in a vacuum oven at 50°C for 24 hours to obtain cage-type diphenylsulfone silsesquioxane with a yield of 3.17g. The obtained cage diphenylsulfone-based silsesquioxane is silsesquioxane cont...

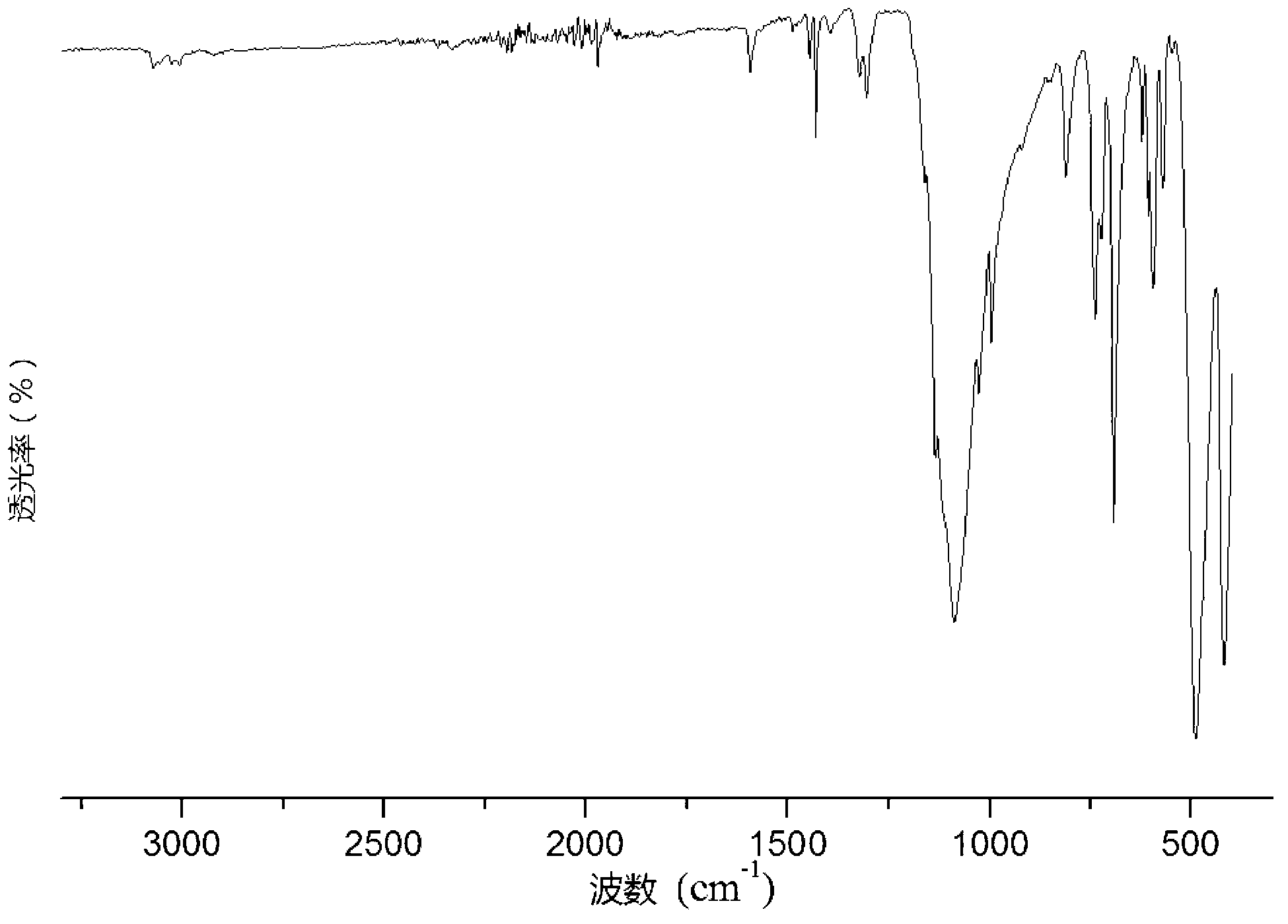

Embodiment 2

[0037]1) Add 5.17g of cage-type octaphenylsilsesquioxane and 20ml of dichloromethane into a 100ml three-neck flask equipped with a reflux condenser, constant pressure dropping funnel, temperature control device, argon protection and magnetic stirring, Stir, the temperature is 25°C, add 5.33g of aluminum trichloride in two times with an interval of 10 minutes, then add 7.08g of benzenesulfonyl chloride dropwise, and react for 48 hours after the dropwise addition to obtain a reaction solution;

[0038] 2) Filter the reaction solution obtained in step 1), place the filtrate in a conical separatory funnel, wash it 3 times with a mixture of 200ml hydrochloric acid and ice water (the volume ratio of hydrochloric acid and ice water is 1:1), and then The organic layer was added to 500ml of ethanol to precipitate a precipitate, which was dried in a vacuum oven at 50°C for 24 hours to obtain cage-type diphenylsulfone silsesquioxane with a yield of 4.42g. The obtained cage diphenylsulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com