Thermoplastic resin composite material notebook computer C shell and manufacturing process thereof

A notebook computer, thermoplastic resin technology, applied in the field of notebook computer shell processing, can solve the problems that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

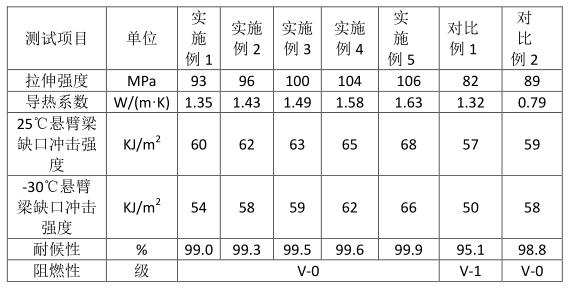

Examples

preparation example Construction

[0030] Preferably, the preparation method of dimethyl carbonate oxadiazole benzotriazolyl butylphenol sulfonate comprises the following steps: 2,5-bis(diethylamino)phenyl-1,3, Add 5-oxadiazole and dimethyl chloromethyl carbonate into the organic solvent, stir and react at 40-60°C for 3-5 hours, then remove the solvent by rotary evaporation, and then add benzotriazolyl butylphenolsulfonic acid to it Sodium and water, stirred and reacted at 60-80°C for 4-6 hours, and then filtered to remove water to obtain dimethyl carbonate oxadiazole benzotriazolyl butylphenol sulfonate.

[0031] Preferably, the 2,5-bis(diethylamino)phenyl-1,3,5-oxadiazole, dimethyl chloromethyl carbonate, organic solvent, sodium benzotriazolyl butylphenol sulfonate, The molar ratio of water is 1:2:(6-15):2:(25-45).

[0032] Preferably, the organic solvent is at least one of dimethylsulfoxide, N,N-dimethylformamide, and N-methylpyrrolidone.

[0033] Preferably, the coupling agent is silane coupling agent KH-...

Embodiment 1

[0046] A thermoplastic resin composite notebook computer C shell is characterized in that it is made of the following raw materials in parts by weight: 40 parts of carbonyl-terminated hyperbranched polycarbonate, 8 parts of waste polyarylene oxadiazole fiber, PBT 30 parts of resin, 3 parts of coupling agent, 3 parts of dimethyl carbonate oxadiazole benzotriazolyl butylphenol sulfonate, 5 parts of graphene fiber, 4 parts of glass fiber, 1 part of antioxidant, compatibility 3 parts of agent, 1 part of lubricant.

[0047] The lubricant is paraffin; the compatibilizer is maleic anhydride grafted polyethylene; the antioxidant is antioxidant 168; the average diameter of the glass fiber is 5 μm, and the aspect ratio is 15:1; The graphene fiber has an average diameter of 3 μm and an aspect ratio of 13:1.

[0048] The preparation method of the dimethyl carbonate oxadiazole benzotriazolyl butylphenol sulfonate comprises the following steps: 2,5-bis(diethylamino)phenyl-1,3,5-di Add oxa...

Embodiment 2

[0053] A thermoplastic resin composite notebook computer C shell and its manufacturing process, which are basically the same as Example 1, the difference is that it is made from the following raw materials in parts by weight: 42 parts of carbonyl-terminated hyperbranched polycarbonate , 9 parts of waste polyarylene oxadiazole fiber, 32 parts of PBT resin, 3.5 parts of coupling agent, 4 parts of dimethyl carbonate oxadiazole benzotriazolyl butylphenol sulfonate, 6 parts of graphene fiber, glass 4.5 parts of fiber, 1.2 parts of antioxidant, 3.5 parts of compatibilizer, and 1.5 parts of lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com