Epoxy resin system for producing telegraph poles and preparation method of epoxy resin system

An epoxy resin system, epoxy resin technology, applied in the field of chemical materials, can solve the problems of low heat resistance, high transportation cost, heavy weight and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of epoxy resin system of present embodiment, comprises A component and B component,

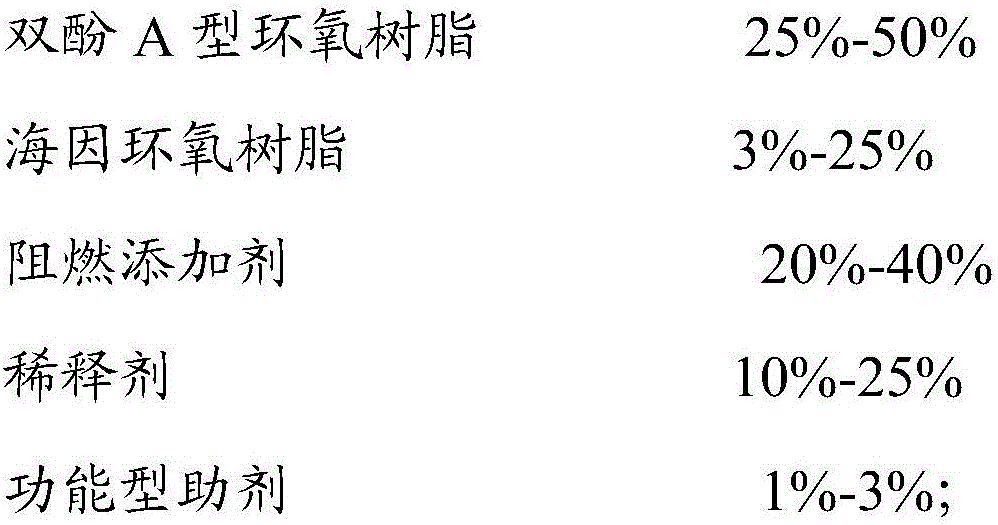

[0034] Component A includes by mass percent:

[0035]

[0036]

[0037] Component B, in terms of mass percentage, includes:

[0038] Methylhexahydrophthalic anhydride 93%

[0039] Benzyltriphenylphosphine bromide 5%

[0040] Polyacrylic acid (leveling agent) 2%

[0041] The preparation method of above-mentioned epoxy resin system, comprises the steps:

[0042] According to the above mass ratio, bisphenol A type epoxy resin and hydantoin epoxy resin (viscosity of 2800-3800mpa.s (25°C) with a high viscosity of 4000-13000mpa. ℃), epoxy value 0.72-0.79), flame retardant additives (specifically: tetrabromobisphenol A type brominated epoxy resin) and diluent (specifically: 1,4-butanediol diglycidyl ether) Put it into the reaction kettle, set the vacuum to 220mmHg-350mmHg, raise the temperature to 55°C-70°C, stir and mix at a speed of 100R / min-300R / min for 2 hours, and then ...

Embodiment 2

[0063] A kind of epoxy resin system of present embodiment, comprises A component and B component,

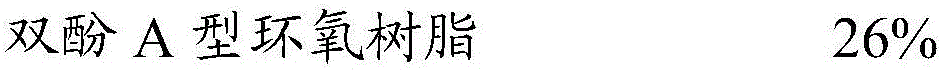

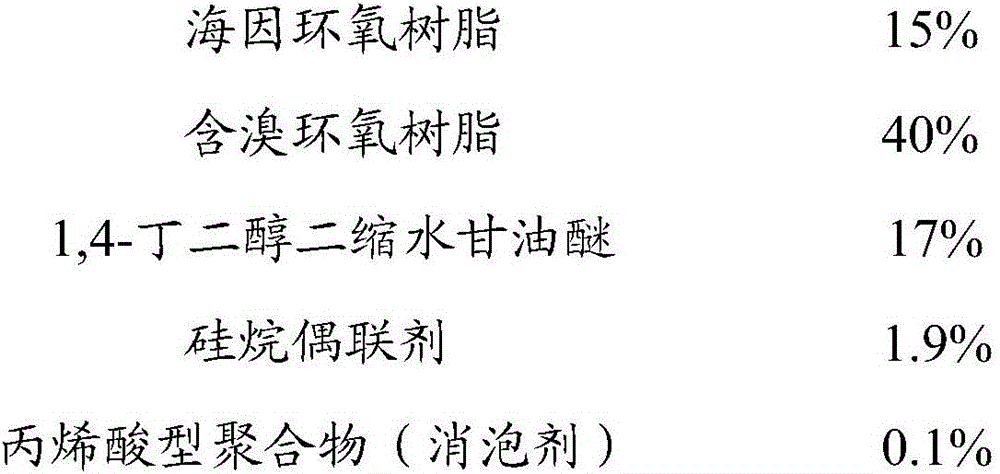

[0064] Component A includes by mass percent:

[0065]

[0066]

[0067] Component B, in terms of mass percentage, includes:

[0068] Methylhexahydrophthalic anhydride 96%

[0069] DMP-30 3%

[0070] Polyacrylic acid (leveling agent) 1%.

[0071] The preparation method of above-mentioned epoxy resin system, comprises the steps:

[0072] According to the above mass ratio, bisphenol A type epoxy resin and hydantoin epoxy resin (viscosity of 2800-3800mpa.s (25°C) with a high viscosity of 4000-13000mpa. ℃), epoxy value 0.72-0.79), flame retardant additives (specifically: tetrabromobisphenol A type brominated epoxy resin) and diluent (specifically: 1,4-butanediol diglycidyl ether) Put it into the reaction kettle, set the vacuum to 220mmHg-350mmHg, raise the temperature to 55°C-70°C, stir and mix at a speed of 100R / min-300R / min for 2 hours, and then add functional additives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com