Flame-retardant resin composition, insulating electric wire and wire harness

A technology of flame retardant resin and composition, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of increased manufacturing cost and expensive magnesium hydroxide, and achieve high reliability, excellent flexibility, and suppression of deterioration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

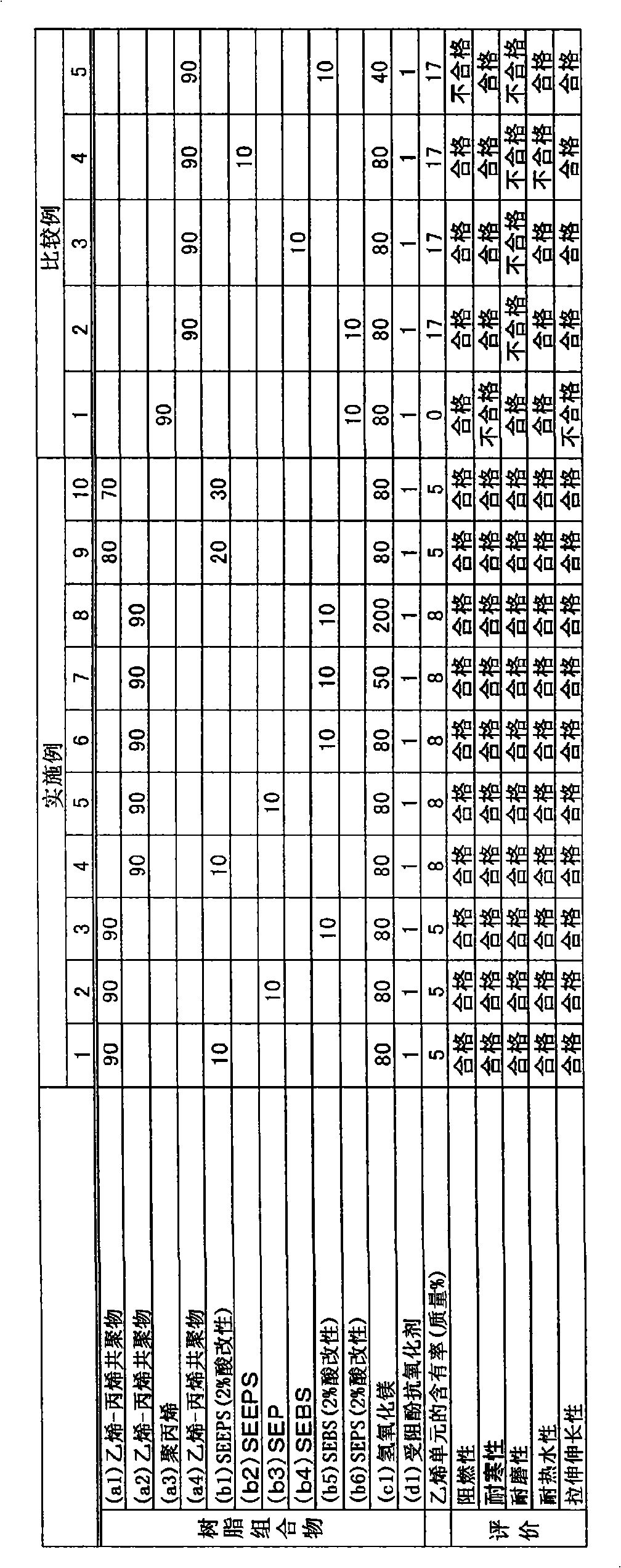

[0082] Preparation of flame retardant composition and insulated wire

[0083] First, the components shown in the table below were kneaded at a mixing temperature of 250° C. using a twin-screw extruder, and pelletized using a pelletizer. Thus, the flame-retardant resin composition of the example and the flame-retardant resin composition according to the comparative example were obtained. Then, using a 50mm extruder, a conductor (cross-sectional area: 0.5mm 2 ) (which is an annealed copper strand prepared by twisting seven annealed copper electric wires) was extruded to have a thickness of 0.25 mm, thereby preparing insulated wires of Examples and Comparative Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com