3D printing method for magnesium alloy-polymer composite biodegradable biological scaffold

A 3D printing and bio-scaffold technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as inflammation, treatment failure, hidden dangers, etc., to control degradation time, enhance mechanical and structural properties, and solve excessive degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

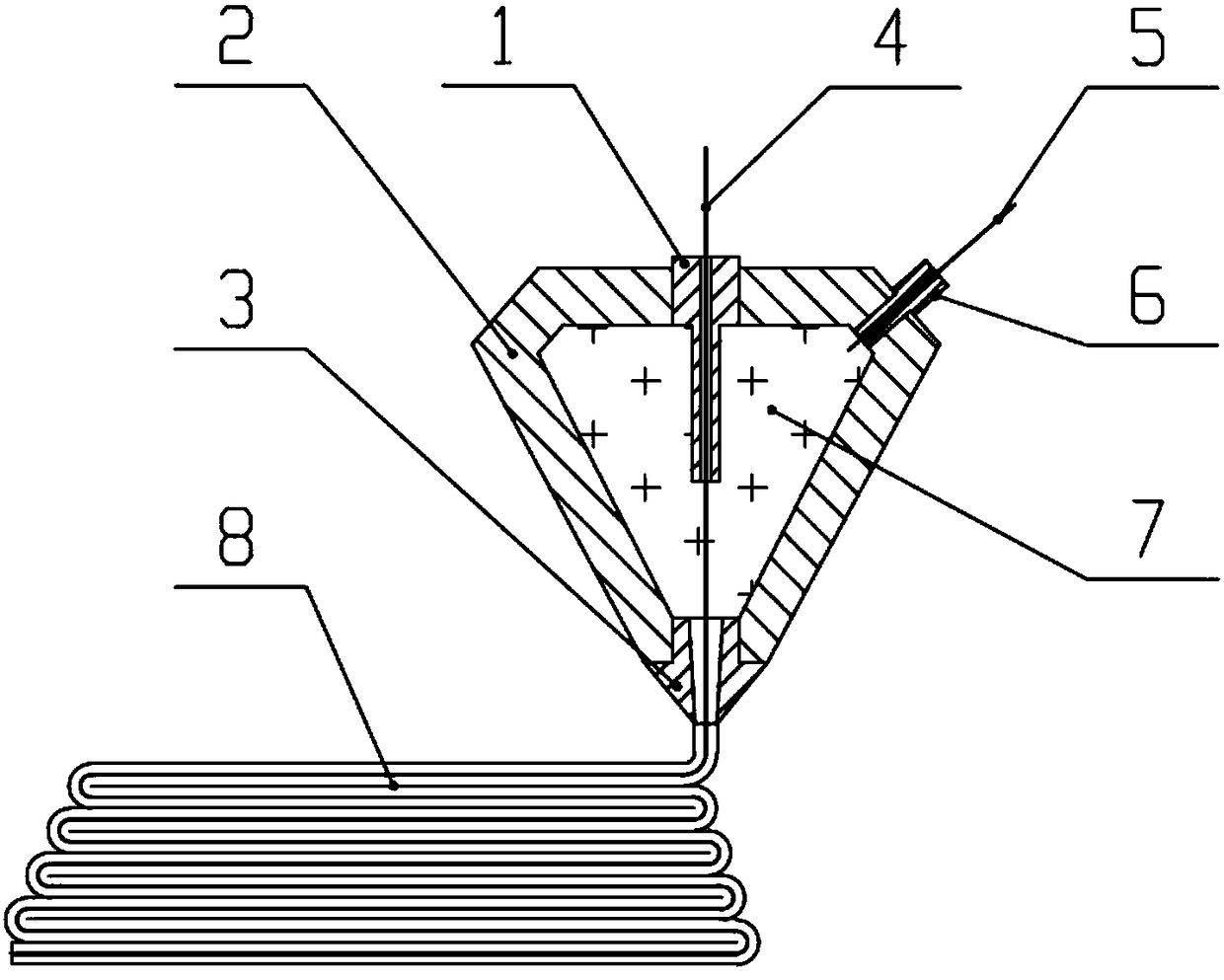

[0019] refer to figure 1 , a 3D printing method for a magnesium alloy-polymer composite degradable bioscaffold, comprising the following steps: firstly making degradable magnesium alloy materials into degradable magnesium alloy fibers 4 of different diameters with different mechanical properties; The alloy fiber 4 passes through the nozzle 3 of the coaxial 3D printing nozzle; then a degradable polymer 5 material is added to the inner hot melt cavity 7 of the coaxial 3D printing nozzle, and the degradable polymer 5 will be degradable after melting The magnesium alloy fiber 4 and the melted degradable polymer 5 are jointly extruded from the nozzle 3 to form a degradable magnesium alloy-polymer composite reinforcing fiber; finally, under the control of the 3D printing system, 3D Printing to obtain a magnesium alloy-polymer composite reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com