Antibacterial polyurethane foam material and preparation method and application thereof

A technology of polyurethane foam and polyester polyol, applied in application, surgery, surgical adhesives, etc., can solve the problems of high cost and unsatisfactory effect, and achieve low biotoxicity, long-term stable antibacterial, and biocompatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

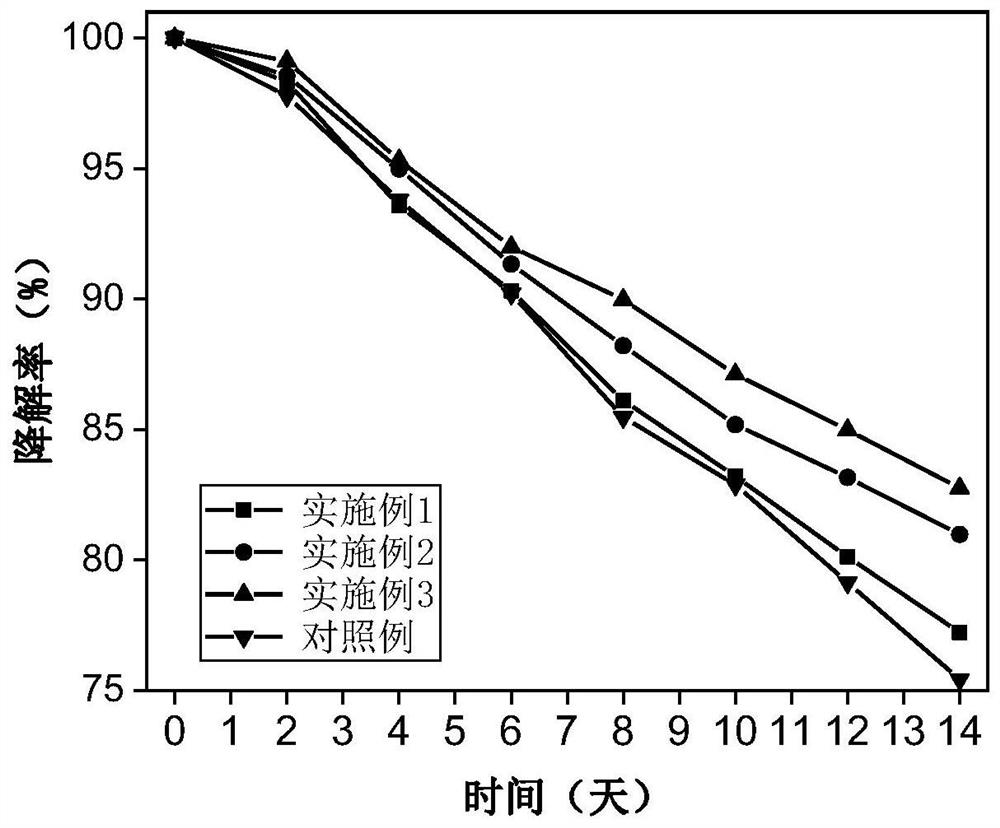

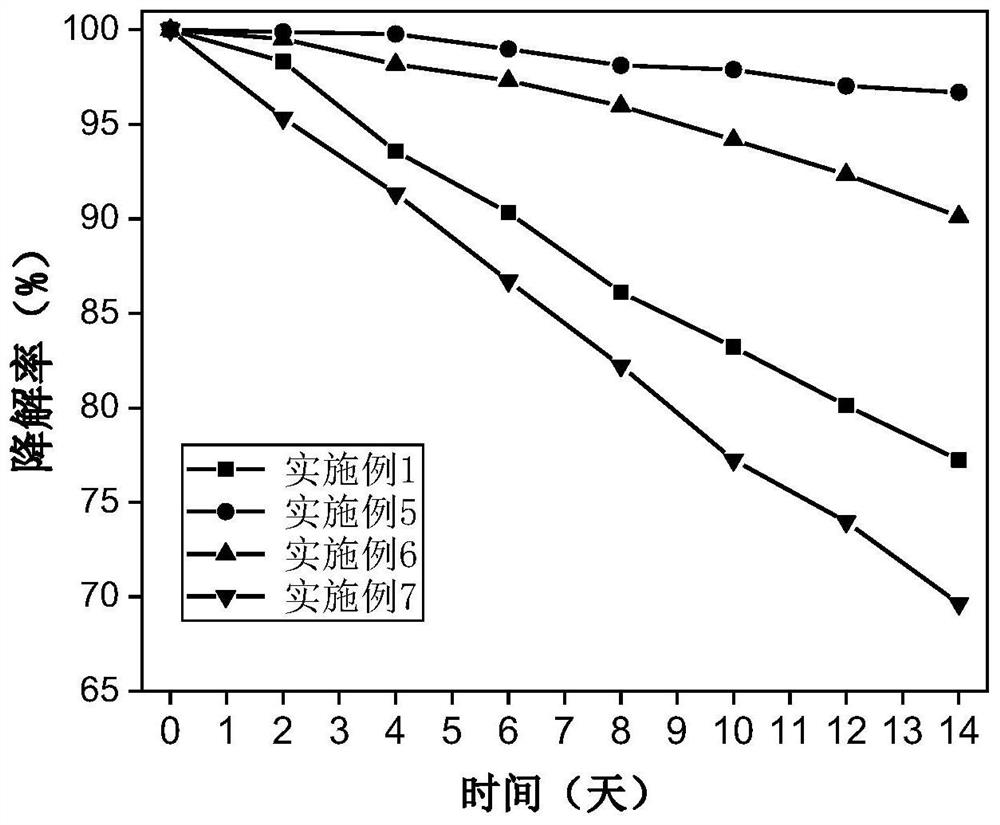

Examples

Embodiment 1

[0038] The preparation method of antibacterial polyurethane nasal cavity hemostatic material:

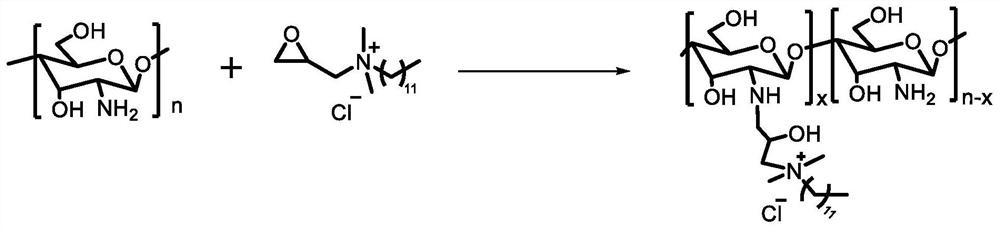

[0039] S1. Preparation of quaternized chitosan: Weigh 10g of chitosan, add 150ml of 20% concentration of epoxypropyl dimethyl dodecyl ammonium chloride solution, heat to 80°C for constant temperature reaction for 12h, wash and dry Process to obtain powdery quaternized chitosan QCS-12.

[0040] S2, mix 70g polyethylene glycol (molecular weight 1000) and 30g polycaprolactone diol (molecular weight 1000) after removing water, add the aqueous solution of QCS-12, catalyst (stannous octoate and triethylenediamine), Foam stabilizer L-580 is stirred at 500r / min for 1-2min and then the temperature of the material is kept to 50°C.

[0041]S3. Then, add 15g of isophorone diisocyanate to the mixture under stirring at 3000r / min, stir for 10-60s, pour it into a mold, foam at room temperature, and ripen at 80°C for 1h after the foam is debonded , and finally aged at room temperature for 7 days t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com