Material and preparation method and application thereof

A technology for structural layer and resin degradation, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of adverse effects of degradation performance, slow and fast, partial analysis and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

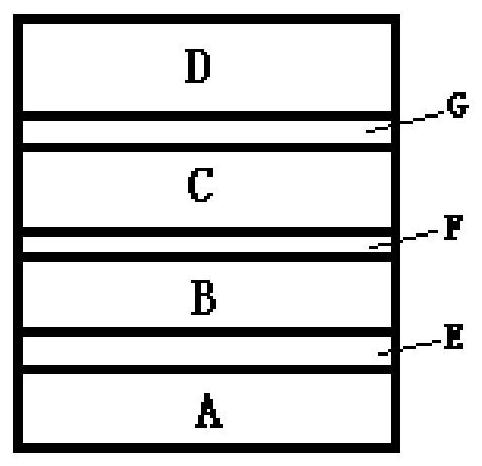

[0092] Using the glycolic acid homopolymer with a relative molecular mass of 243,000, using the calendering method, controlling the cooling temperature to 130 ° C and the cooling rate to 1 ° C / min, a structural layer A with a crystallinity of about 70% can be obtained. The relative molecular mass of 24.3 Wan's glycolic acid homopolymer adopts the extrusion molding method, and the cooling temperature is controlled to be 100 ° C and the cooling rate is 3 ° C / min, and the structural layer B with a crystallinity of about 62% can be obtained. The homopolymer adopts the calendering molding method, the cooling temperature is controlled to be 90 °C, and the cooling rate is 10 °C / min, and a structural layer C with a crystallinity of about 56% can be obtained. The molding method is used, and the cooling temperature is controlled to be 80 °C and the cooling rate is 25 °C / min, and a structural layer D with a crystallinity of about 41% can be obtained;

[0093] The structural layer A and t...

Embodiment 2

[0100] Using the glycolic acid homopolymer with a relative molecular mass of 124,000, the calendering method is used, the cooling temperature is controlled to 150 ° C, and the cooling rate is 0.5 ° C / min, and a structural layer A with a crystallinity of about 70% can be obtained. The relative molecular mass of 18.5 Wan's glycolic acid homopolymer adopts the extrusion molding method, the cooling temperature is controlled to 120°C, and the cooling rate is 2°C / min, and the structural layer B with a crystallinity of about 62% can be obtained. The homopolymer adopts the calendering method, the cooling temperature is controlled to be 100 °C, and the cooling rate is 10 °C / min, and a structural layer C with a crystallinity of about 56% can be obtained. A molding method is developed, the cooling temperature is controlled to be 75°C, and the cooling rate is 15°C / min, and a structural layer D with a crystallinity of about 41% can be obtained;

[0101] The structural layer A and the struc...

Embodiment 3

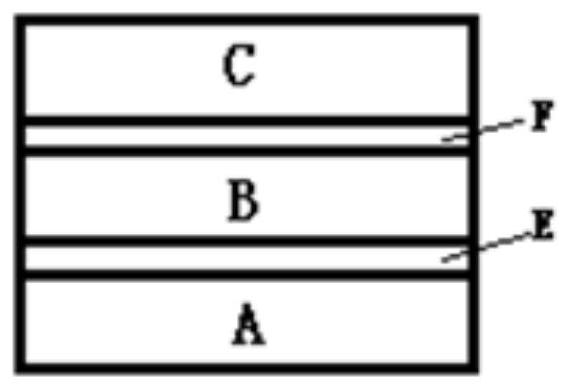

[0105] Using a glycolic acid homopolymer with a relative molecular mass of 243,000, referring to the process for obtaining the structural layer A in Example 1, a single-layer material with a crystallinity of about 70% was obtained, and its thickness was the same as that obtained in Example 1 or 2. figure 2 The materials shown are the same.

[0106] According to the GB / T 1042 method, the obtained samples of Examples 1 and 2 were obtained respectively. figure 2 The materials shown and the monolayer materials obtained above were tested for material elongation at break.

[0107] According to the method of GB / T 1043, respectively, for example 1 and 2 obtained as figure 2 The materials shown and the monolayer materials obtained above were tested for material impact strength.

[0108] The results are shown in Tables 2 and 3.

[0109] Table 2

[0110]

[0111] table 3

[0112]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com