A kind of tpu film with controllable degradation time and preparation method thereof

A degradation time, film technology, applied in the fields of botanical equipment and methods, flat products, other household appliances, etc., can solve problems such as affecting growth and failing to achieve controllable degradation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

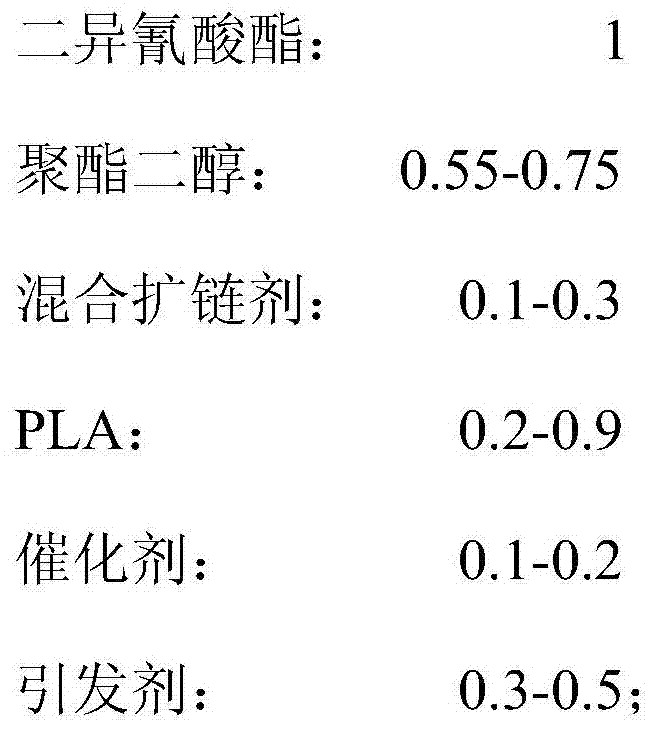

[0050] The raw material of the TPU of grafting PLA comprises by molar ratio in the present embodiment:

[0051]

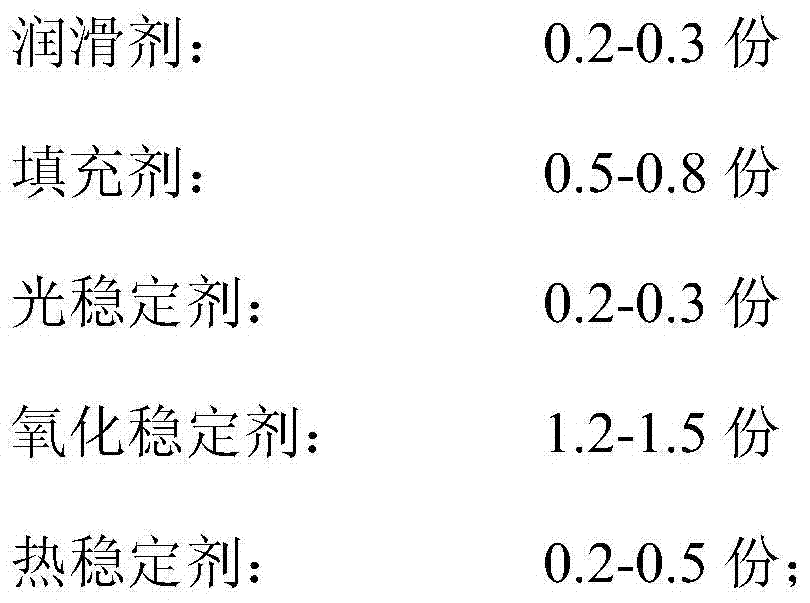

[0052] Calculated as 10 parts by weight of diisocyanate, the raw materials also include:

[0053]

[0054]

[0055] The present embodiment adopts following method to carry out the preparation of TPU film:

[0056] (1) Mix diisocyanate, polyester diol, mixed chain extender, lubricant, catalyst, filler, light stabilizer, oxidation stabilizer and heat stabilizer evenly, heat to 175-185°C, and extrude through a single screw Extrude out of the machine to form TPU melt;

[0057] (2) Dissolve PLA in a tetrahydrofuran solution with a concentration of 0.5 mol / L, heat up to 65°C after introducing an inert gas, and reflux at a constant temperature. Add the initiator and TPU melt in 4 times within 5 minutes, and the amount added at the last time is equal to The amount added at the previous time; wash with distilled water, repeat three times, each time greater than o...

Embodiment 2

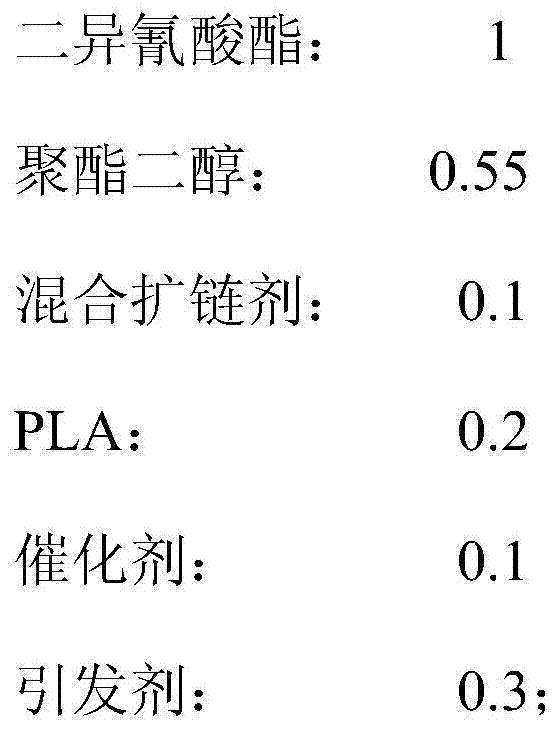

[0060] The raw material of the TPU of grafting PLA comprises by molar ratio in the present embodiment:

[0061]

[0062] Calculated as 10 parts by weight of diisocyanate, the raw materials also include:

[0063]

[0064]

[0065] The present embodiment adopts following method to carry out the preparation of TPU film:

[0066] (1) Mix diisocyanate, polyester diol, mixed chain extender, lubricant, catalyst, filler, light stabilizer, oxidation stabilizer and heat stabilizer evenly, heat to 175-185°C, and extrude through a single screw Extrude out of the machine to form TPU melt;

[0067] (2) Dissolve PLA in a tetrahydrofuran solution with a concentration of 2.5 mol / L, heat up to 75°C after passing through an inert gas, reflux at a constant temperature, add the initiator and TPU melt in 4 times within 5 minutes, and the amount added at the last time is greater than The amount added in the previous time; washed with distilled water, repeated 5 times, each time greater th...

Embodiment 3

[0070] The raw material of the TPU of grafting PLA comprises by molar ratio in the present embodiment:

[0071]

[0072] Calculated as 10 parts by weight of diisocyanate, the raw materials also include:

[0073]

[0074]The present embodiment adopts following method to carry out the preparation of TPU film:

[0075] (1) Mix diisocyanate, polyester diol, mixed chain extender, catalyst, lubricant, light stabilizer, oxidation stabilizer and heat stabilizer evenly, heat to 175-185°C, and extrude through a single-screw extruder Form TPU melt;

[0076] (2) Dissolve PLA in a tetrahydrofuran solution with a concentration of 2.5mol / L, heat up to 75°C after passing through an inert gas, and reflux at a constant temperature. Add the initiator and TPU melt in 4 times within 5 minutes, and the amount added at the last time is equal to The amount added at the previous time; wash with distilled water, repeat three times, each time greater than or equal to 10min, to obtain TPU grafted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com