Macromolecular material based on modified montmorillonite clay and preparation method thereof

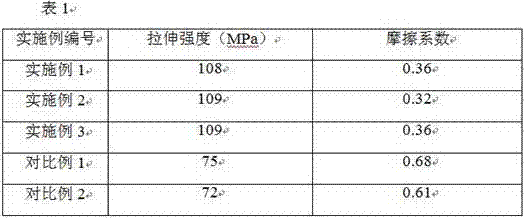

A technology of polymer materials and montmorillonite, which is applied in the field of polymer materials, can solve the problems of insufficient mechanical properties of composite materials, poor resin compatibility, poor dispersion, etc., and achieve excellent mechanical properties, low friction coefficient, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of the polymer material based on modified montmorillonite, and described preparation method comprises:

[0014] (1) Mix montmorillonite, silane coupling agent and absolute ethanol, and obtain modified montmorillonite after filtering;

[0015] (2) Mix modified montmorillonite, methacrylic acid, polyvinyl chloride, xylene, polylactic acid and ethylene glycol to obtain a mixed solution M, and thermoform the mixed solution to obtain a copolymer plate;

[0016] (3) adding the copolymer plate into the liquid resin matrix to obtain a mixed solution N, and thermoforming the mixed solution N to obtain a polymer material based on modified montmorillonite.

[0017] In a preferred embodiment of the present invention, in order to further improve the mechanical properties of the prepared polymer material, relative to 100 parts by weight of montmorillonite, the amount of the silane coupling agent is 10-20 parts by weight, The consum...

Embodiment 1

[0028] Mix 100g of montmorillonite, 10g of silane coupling agent and 180g of absolute ethanol (using ultrasonic dispersion, and the frequency of ultrasonic dispersion is 20kHz, and the time of ultrasonic dispersion is 10min), and filter to obtain modified montmorillonite; 100g of modified montmorillonite, 20g of methacrylic acid, 10g of polyvinyl chloride, 1g of xylene, 50g of polylactic acid and 50g of ethylene glycol are mixed to obtain a mixed solution M, and the mixed solution is thermoformed (the thermoforming temperature is 150°C, The thermoforming time is 30min) to obtain a copolymer plate; 100g of the copolymer plate is added to 400g of liquid epoxy resin matrix to obtain a mixed solution N, and the mixed solution N is thermoformed (the thermoforming temperature is 170°C , the thermoforming time is 20min) to obtain the polymer material A1 based on modified montmorillonite.

Embodiment 2

[0030] Mix 100g of montmorillonite, 20g of silane coupling agent and 220g of absolute ethanol (using ultrasonic dispersion, and the frequency of ultrasonic dispersion is 30kHz, and the time of ultrasonic dispersion is 20min), and then filter to obtain modified montmorillonite; 100g of modified montmorillonite, 30g of methacrylic acid, 20g of polyvinyl chloride, 5g of xylene, 70g of polylactic acid and 80g of ethylene glycol were mixed to obtain a mixed solution M, and the mixed solution was thermoformed (the thermoforming temperature was 160°C, The thermoforming time is 40min) to obtain a copolymer plate; 100g of the copolymer plate is added to 600g of liquid bis-horse resin matrix to obtain a mixed solution N, and the mixed solution N is thermoformed (the thermoforming temperature is 180°C , the thermoforming time is 30min) to obtain the polymer material A2 based on modified montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com