Rapid molding high heat-resistant polyamide-polyphenyl ether alloy and preparation method thereof

A technology of high heat resistance and polyamide, which is applied in the field of rapid prototyping high heat resistance polyamide-polyphenylene ether alloy and its preparation, and can solve problems such as no obvious improvement in chemical resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

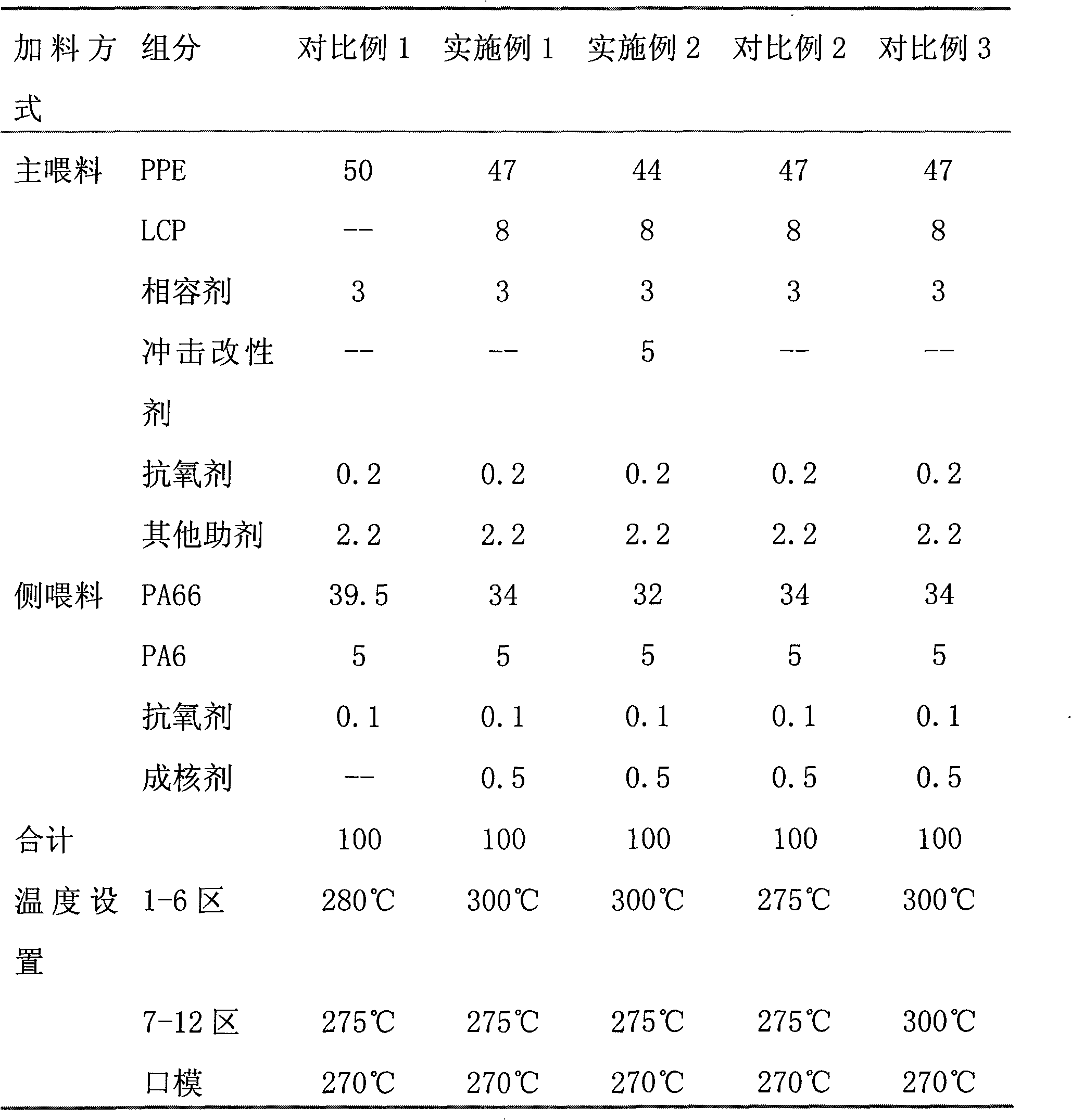

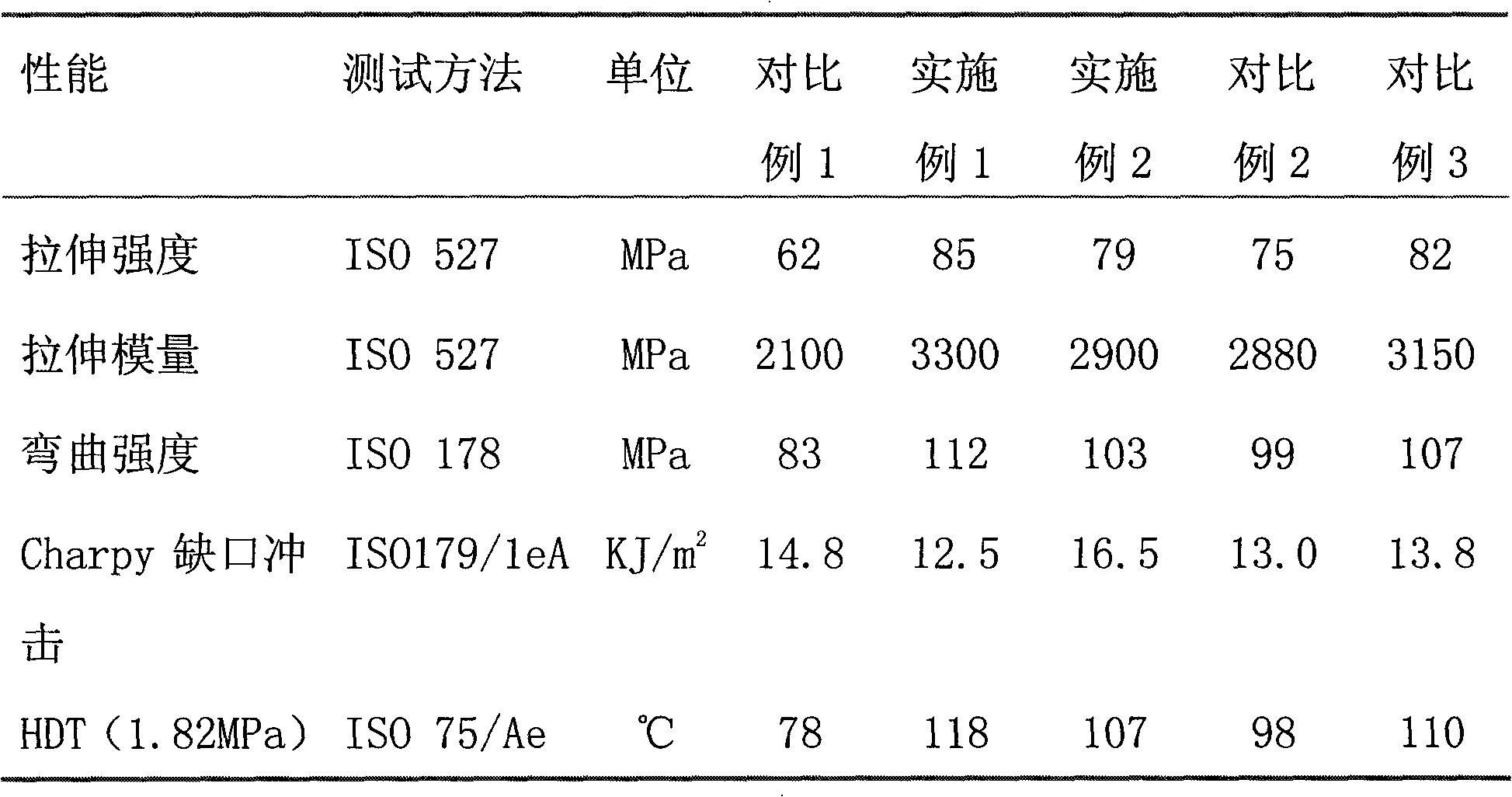

[0028] The production method of the present invention is illustrated as follows, but the present invention is not limited to the following examples.

[0029] raw material:

[0030] PPE: Poly(2,6-dimethyl-1,4-phenylene ether), Ruicheng Branch of Bluestar Chemical New Materials Co., Ltd., LXR050, with an intrinsic viscosity of 0.50dl / g;

[0031] PA66: Basf 1310-11 NF2001;

[0032] PA6: Basf 8270HS;

[0033] LCP: Ticona A950;

[0034] Compatibilizer: SMA 1000;

[0035] Nucleating agent: Clariant Cav 102;

[0036] Impact modifiers: SEBS G1651;

[0037] Antioxidant: Ciba 1010: 168=1:2;

[0038] First mix polyphenylene ether, liquid crystal polymer resin, compatibilizer, impact modifier, some antioxidants and other additives through a high-speed mixer, and then directly enter the twin-screw extruder through the main feed, while PA66 and PA6 resin, nucleating agent and other antioxidants are fed into the twin-screw extruder through side feeding, and then packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com