Irradiation crosslinked polyethylene blending material for artificial joints and preparation method thereof

A technology of cross-linked polyethylene and artificial joints, applied in medical science, prosthesis, etc., can solve problems such as inability to process, and achieve the effect of easy maintenance of orientation and increased impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

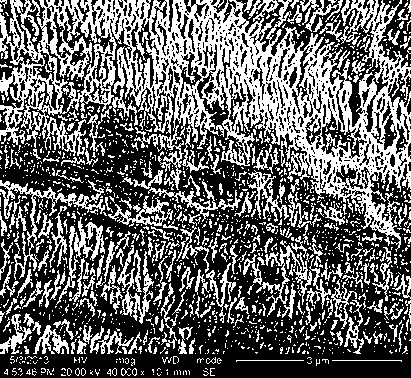

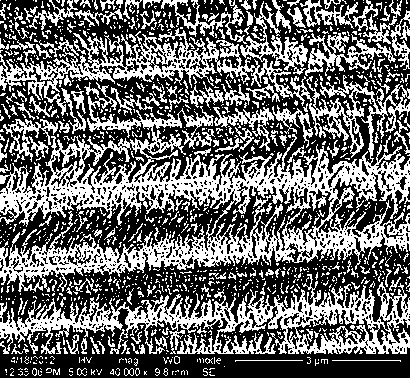

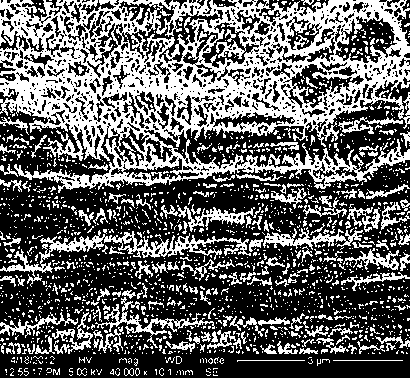

Image

Examples

Embodiment 1

[0030] (1) Preparation of irradiation cross-linked UHMWPE: UHMWPE powder was irradiated with electron beams in the air, the irradiation dose was selected as 30 kGy, and then the irradiated samples were placed under nitrogen protection to prevent oxidative degradation .

[0031] (2) Preparation of LMWPE masterbatch: Mechanically mix unirradiated ultra-high molecular weight polyethylene powder and low molecular weight polyethylene at a mass ratio of 1:49, add xylene solution and blend until a homogeneous transparent solution is formed , and then kept stirring at 135 °C for 60 min. The obtained solution was injected into ethanol at room temperature, and the volume of ethanol was 3 times that of the solution, so that the UHMWPE / LMWPE blend containing 2% UHMWPE was precipitated, then filtered, and the filtrate was dried at 100 ° C for 12 hours;

[0032] (3) Preparation of irradiation cross-linked UHMWPE / LMWPE blend: After mechanically mixing the irradiated UHMWPE and LMWPE masterb...

Embodiment 2

[0035] (1) Preparation of irradiation cross-linked UHMWPE: UHMWPE powder was irradiated with electron beams in air, the irradiation dose was selected as 40 kGy, and then the irradiated samples were placed under nitrogen protection to prevent oxidative degradation .

[0036] (2) Preparation of LMWPE masterbatch: Mechanically mix unirradiated ultra-high molecular weight polyethylene powder and low molecular weight polyethylene at a mass ratio of 1:49, add xylene solution and blend until a homogeneous transparent solution is formed , and then kept stirring at 140 °C for 70 min. The obtained solution was injected into ethanol at room temperature, and the volume of ethanol was 3 times that of the solution, so that the UHMWPE / LMWPE blend containing 2% UHMWPE was precipitated, then filtered, and the filtrate was dried at 100 ° C for 12 hours;

[0037] (3) Preparation of irradiation cross-linked UHMWPE / LMWPE blend: After mechanically mixing the irradiated UHMWPE and LMWPE masterbatch...

Embodiment 3

[0040] (1) Preparation of irradiation cross-linked UHMWPE: UHMWPE powder was irradiated with electron beams in air, the irradiation dose was selected as 100 kGy, and then the irradiated samples were placed under nitrogen protection to prevent oxidative degradation .

[0041] (2) Preparation of LMWPE masterbatch: Mechanically mix unirradiated ultra-high molecular weight polyethylene powder and low molecular weight polyethylene at a mass ratio of 1:49, add xylene solution and blend until a homogeneous transparent solution is formed , and then kept stirring at 140 °C for 60 min. The obtained solution was injected into ethanol at room temperature, and the volume of ethanol was 3 times that of the solution, so that the UHMWPE / LMWPE blend containing 2% UHMWPE was precipitated, then filtered, and the filtrate was dried at 100 ° C for 12 hours;

[0042] (3) Preparation of irradiation cross-linked UHMWPE / LMWPE blend: After mechanically mixing the irradiated UHMWPE and LMWPE masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com