Self-reinforcing type ceramic fibre pouring material and preparation thereof

A technology for ceramic fibers and castables, applied in the field of castables and their preparation, can solve the problems of smoke pollution, heat insulation of furnace linings, uneven heat preservation performance, weakened combination of matrix and aggregates, etc., and achieves the effect of prolonging the life of furnace bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add aluminum silicate ceramic fiber raw cotton (hereinafter referred to as "fiber cotton") and water into the mixer at a weight ratio of 1:1. The rotation speed of the stirring blade is 100 RMP. After stirring for 10 minutes, cut the fiber cotton into diameters Small fiber clusters of 1-5 mm; filter the above-mentioned small fiber clusters on a vacuum filter to remove part of the water, and then roll the above-mentioned small fiber clusters into compressed fiber particles on the ball forming disc; Soak in silica sol (solid content 30%), then filter out 50% of the liquid in the fiber particles by vacuum filtration, and then put such fiber particles into a heated disc granulator (or cylinder granulator) In the process, the fiber particles are heated while rolling, and the maximum heating temperature is 100°C, and the ceramic fiber particles with a dry silica gel hard shell on the outer layer are obtained, and the void rate in such rigid ceramic fiber particles reaches more...

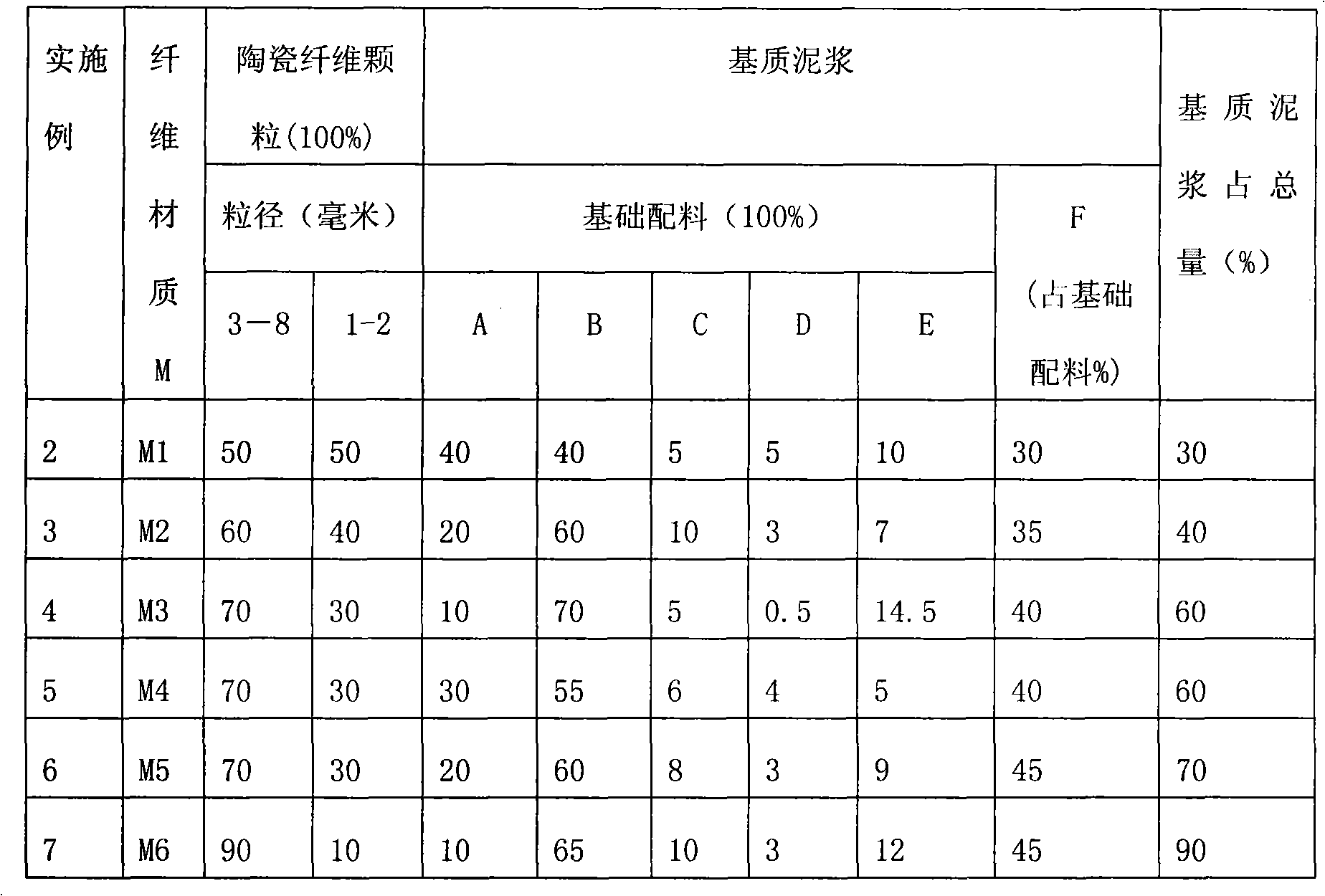

Embodiment 2

[0044] Example 2: C-polystyrene particles, E-alumina cement, the concentration of F is 5%.

Embodiment 3

[0045] Example 3: C-floating beads+expanded perlite fine particles, E-silica sol, and the concentration of F is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com