Preparation method of full-degradable high-strength high-barrier polylactic acid film by in-situ introduction of poly butylene succinate nanosheet

A polybutylene succinate, in-situ introduction technology, applied in the field of high-barrier and high-strength polylactic acid films, can solve the problems of inferior mechanical properties and barrier properties, low toughness of polylactic acid, enlarged polylactic acid, etc., to achieve strength and poor barrier properties, good toughness, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0030] (1) Drying of raw materials: Dry polylactic acid (4032D, NatureWorks, USA) and PBS (Bionolle#1001MD, Showa, Japan) in a blast oven at a constant temperature of 80°C for 12 hours;

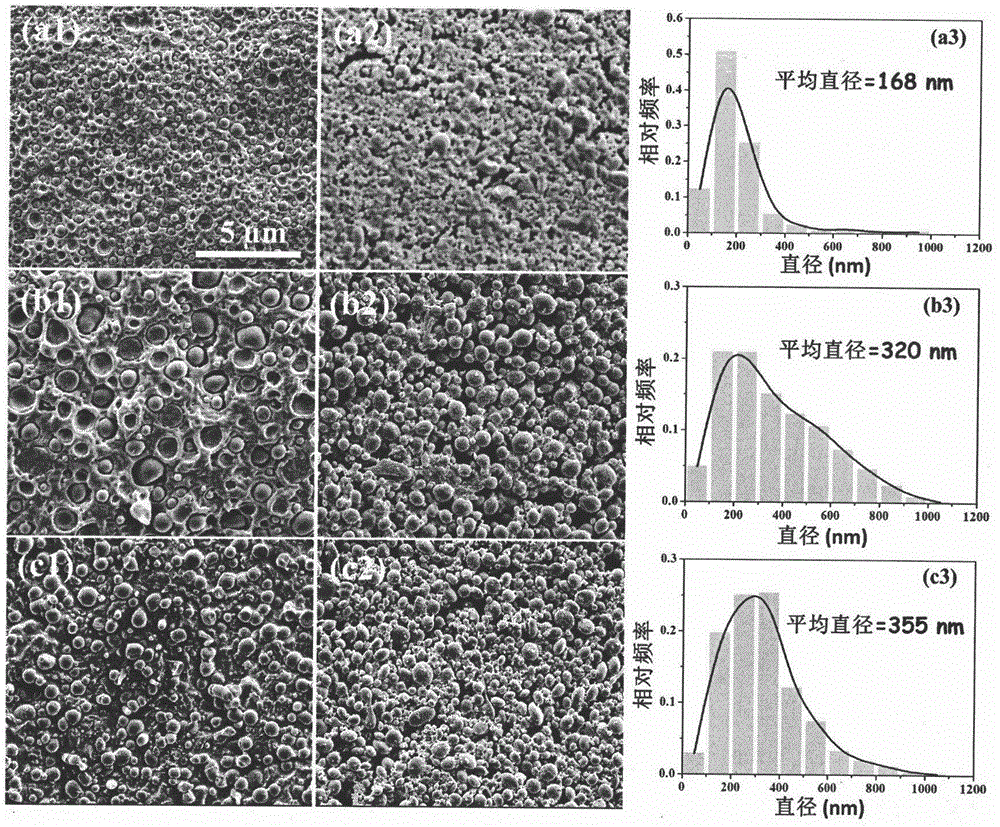

[0031] (2) Melt-blending extrusion: Gained dry polylactic acid and PBS are melt-blended in a twin-screw extruder according to different mass ratios, wherein the mass fraction of PBS is respectively 10wt%, 20wt%, 40wt%, 60wt%, 80wt% and 90wt%, using high feeding speed and screw speed to obtain PBS-containing nanoparticles, the extruded material is exposed to cold air and fully cooled and then cut into pellets. The specific formula is shown in Table 1, and the extrusion blending process parameters are shown in the table 2;

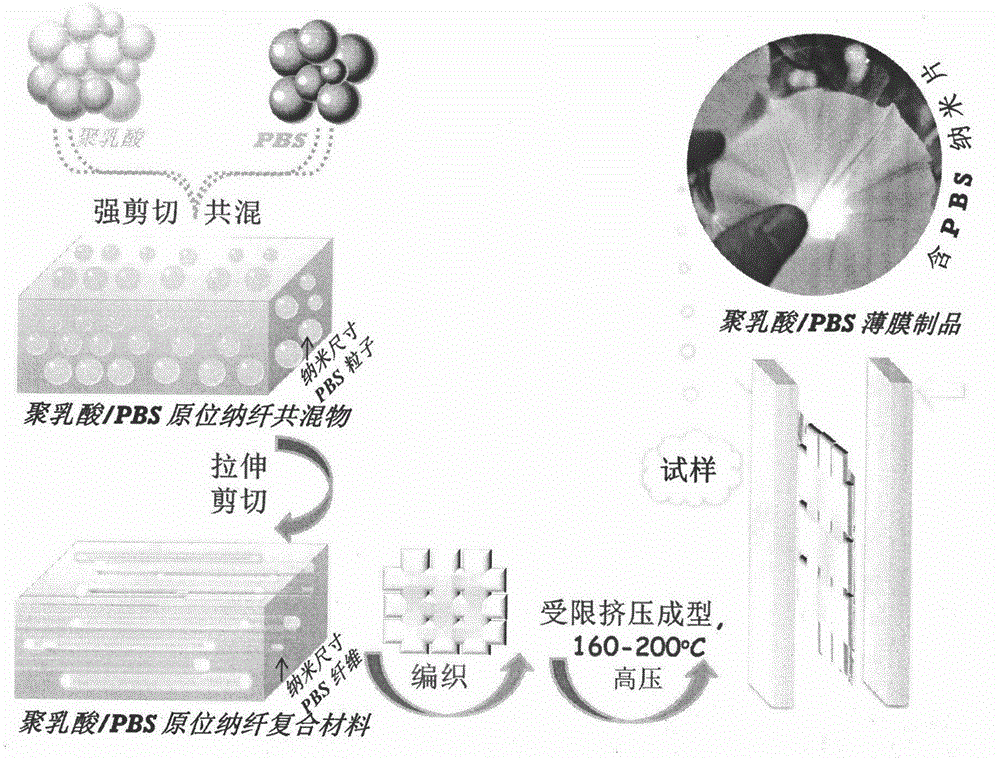

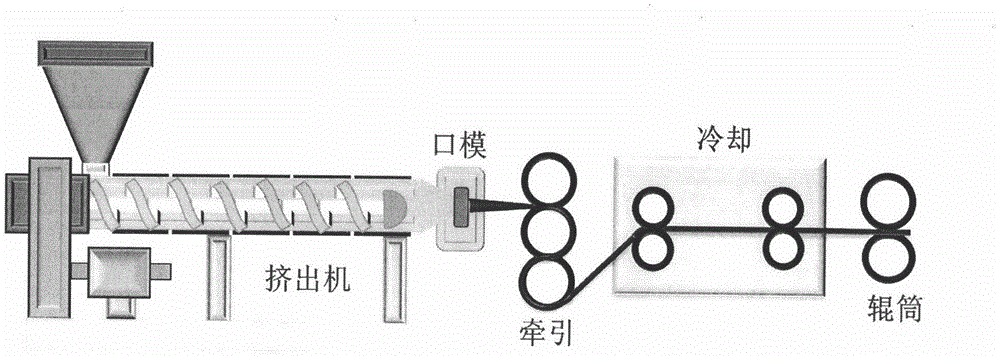

[0032] (3) Form PBS fibers in situ by "slit extrusion-heat stretching-quenching": fully dry the polylactic acid / PBS blended extrusion material so that the moisture weight content is less than 0.01%, and then dry the co-extruded material after drying. The mixture pellets ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com