Preparation method of self-reinforced mullite porous ceramic

A technology of porous ceramics and mullite, which is applied in the field of porous ceramic materials, can solve the problems of low mullite content and low strength, and achieve the effect of improving performance, high strength and high fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 38.4% by mass of kaolin, 31.6% of industrial alumina powder, and 30% of starch are used as raw materials for batching, and 15% of ammonium fluoride is added as an additive, mixed and ball milled for 24 hours, and formed under a pressure of 30MPa. The molded green body is kept at a temperature of 1500° C. for 2 hours to obtain fiber self-reinforced mullite porous ceramics.

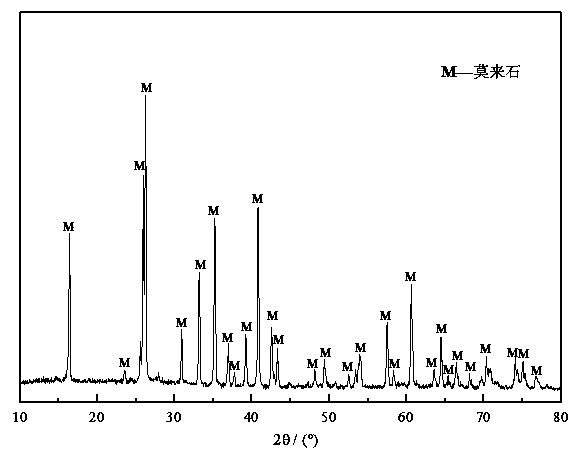

[0013] The product prepared by the method of this embodiment has an apparent porosity of 51%, and a bulk density of 1.53 g / cm 3 , The three-point flexural strength is 48.6MPa. figure 1 and figure 2 From this example, figure 1 It shows that the prepared porous ceramic crystal phase is mullite phase, figure 2 It shows that there are a large number of mullite fibers with acicular structure in porous ceramics.

Embodiment 2

[0015] The mass percentage is 39.6% of Guangxi white mud, 40.4% of industrial alumina powder, 20% of starch as raw materials, and 15% of ammonium fluoride is added as an additive, mixed and ball milled for 24 hours, under a pressure of 30MPa forming. The molded green body is kept at a temperature of 1600° C. for 2 hours to obtain fiber self-reinforced mullite porous ceramics.

[0016] The product prepared by the method of this embodiment has an apparent porosity of 36% and a bulk density of 1.85 g / cm 3 , the three-point flexural strength is 85.4MPa, and there are a large number of rod-shaped mullite fibers in the ceramic matrix.

Embodiment 3

[0018] 36.9% by mass of Guangxi white mud, 33.1% of industrial alumina powder, and 30% of starch are used as raw materials for batching, and 20% of ammonium bifluoride is added as an additive, mixed and ball milled for 24 hours, and formed under a pressure of 30MPa . The molded green body is kept at a temperature of 1400° C. for 2 hours to obtain fiber self-reinforced mullite porous ceramics.

[0019] The product prepared by the method of this embodiment has an apparent porosity of 60% and a bulk density of 1.44 g / cm 3 , the three-point flexural strength is 30.1MPa, and there are a large number of acicular structure mullite fibers in the ceramic matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com