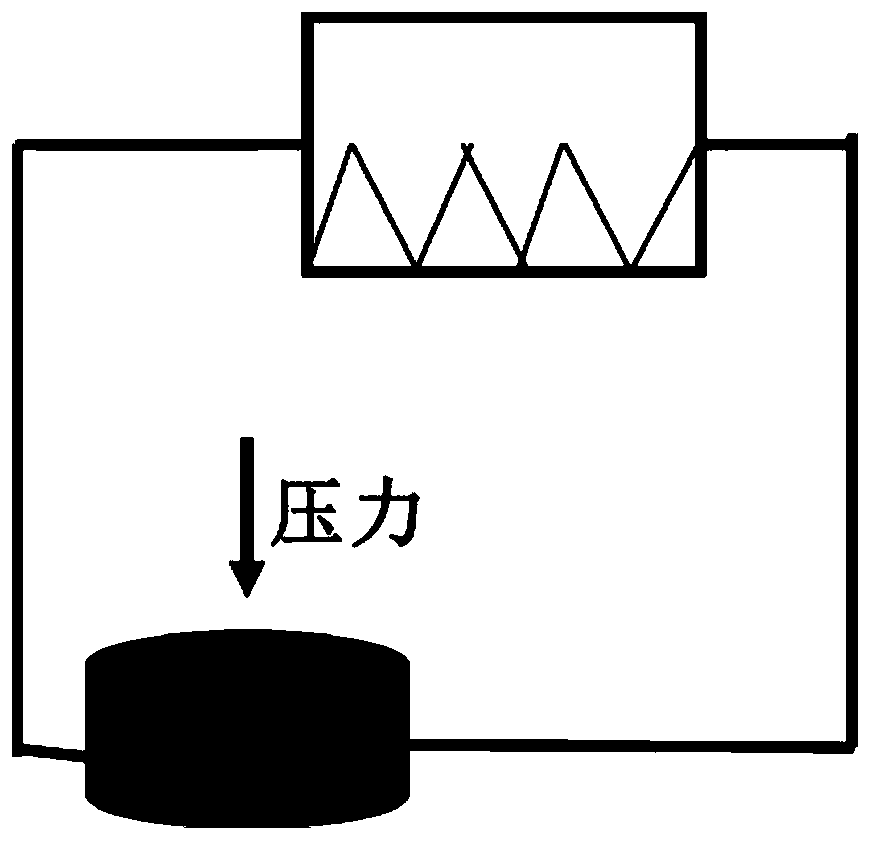

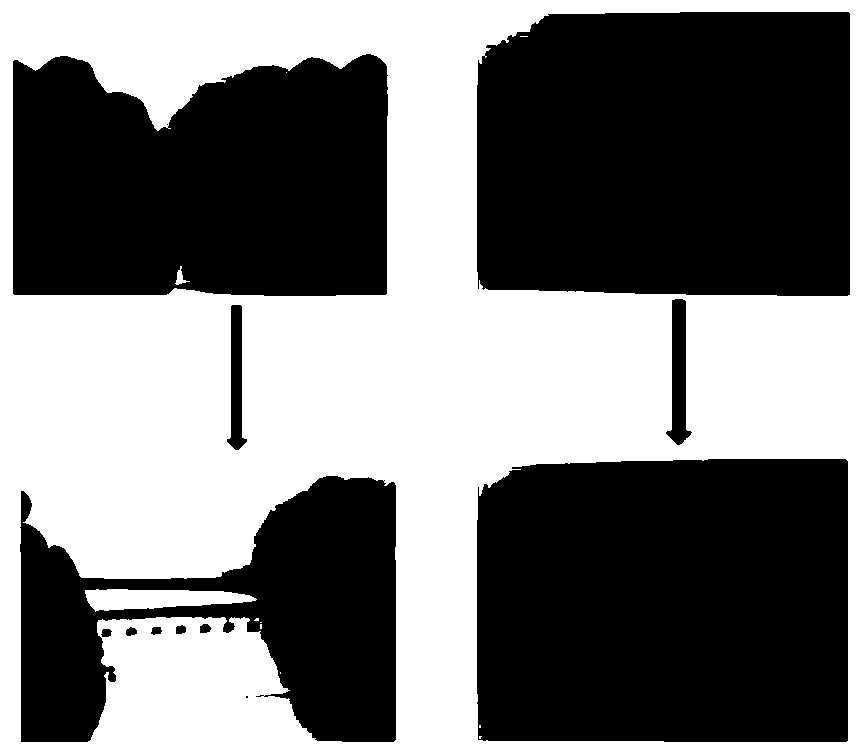

Flexible self-healing conductive hydrogel sensor and preparation method thereof

A conductive hydrogel and hydrogel technology, applied in the measurement of the property force of the piezoelectric resistance material, fluid pressure measurement by changing the ohmic resistance, etc., can solve the problems of complex preparation method, single function, high cost, etc. Achieve excellent sensing performance, satisfy service life, and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Acrylamide monomer (8.3wt%, analytically pure Sinopharm Chemical Reagent Co., Ltd.), cross-linking agent N, N-methylenebisacrylamide (0.1wt%, analytically pure Sinopharm Chemical Reagent Co., Ltd.) Dissolve in deionized water, then blend with acetoacetylated polyvinyl alcohol aqueous solution (16.7wt% relative molecular weight about 90000g / mol, degree of substitution 10%), shake evenly, add initiator potassium persulfate (relative to acrylamide monomer 0.3% of the mass, analytically pure Sinopharm Group Chemical Reagent Co., Ltd.), triggering the polymerization of acrylamide monomers, the polymerization temperature is 25 ° C, and the polymerization time is 2 hours, and the flexible precursor hydrogel can be obtained.

[0038] (2) Soak the above-mentioned precursor hydrogel (5g) in an aqueous solution of ferric chloride (0.5M, 200mL, analytically pure Sinopharm Chemical Reagent Co., Ltd.), and soak for 0.5h to obtain a flexible self-healing conductive hydrogel glue. ...

Embodiment 2

[0040] (1) Dissolve acrylamide monomer (12.5wt%) and cross-linking agent N,N-methylenebisacrylamide (0.1wt%) in deionized water, and then mix with acetoacetated polyvinyl alcohol aqueous solution (12.5wt%) % relative molecular mass of about 90000g / mol, degree of substitution 10%) blending, shaking evenly, adding initiator potassium persulfate (0.3% relative to the mass of acrylamide monomer) to initiate the polymerization of acrylamide monomer, the polymerization temperature is 25°C, The polymerization time is 2h, and the flexible precursor hydrogel can be obtained.

[0041] (2) Soak the above precursor hydrogel (5 g) in ferric chloride aqueous solution (0.5 M, 200 mL) for 0.5 h to obtain a flexible self-healing conductive hydrogel.

Embodiment 3

[0043] (1) Dissolve acrylamide monomer (16.7wt%) and cross-linking agent N,N-methylenebisacrylamide (0.1wt%) in deionized water, and then mix with acetoacetated polyvinyl alcohol aqueous solution (8.3wt%) % relative molecular mass of about 90000g / mol, degree of substitution 10%) blending, shaking evenly, adding initiator potassium persulfate (0.3% relative to the mass of acrylamide monomer) to initiate the polymerization of acrylamide monomer, the polymerization temperature is 25°C, The polymerization time is 2h, and the flexible precursor hydrogel can be obtained.

[0044] (2) Soak the above precursor hydrogel (5 g) in ferric chloride aqueous solution (0.5 M, 200 mL) for 0.5 h to obtain a flexible self-healing conductive hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com