Light sandwich-structure composite material and preparation method thereof

A composite material and sandwich technology, applied in the field of materials, can solve problems such as small bonding area, and achieve the effects of low cost, easy change of product thickness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

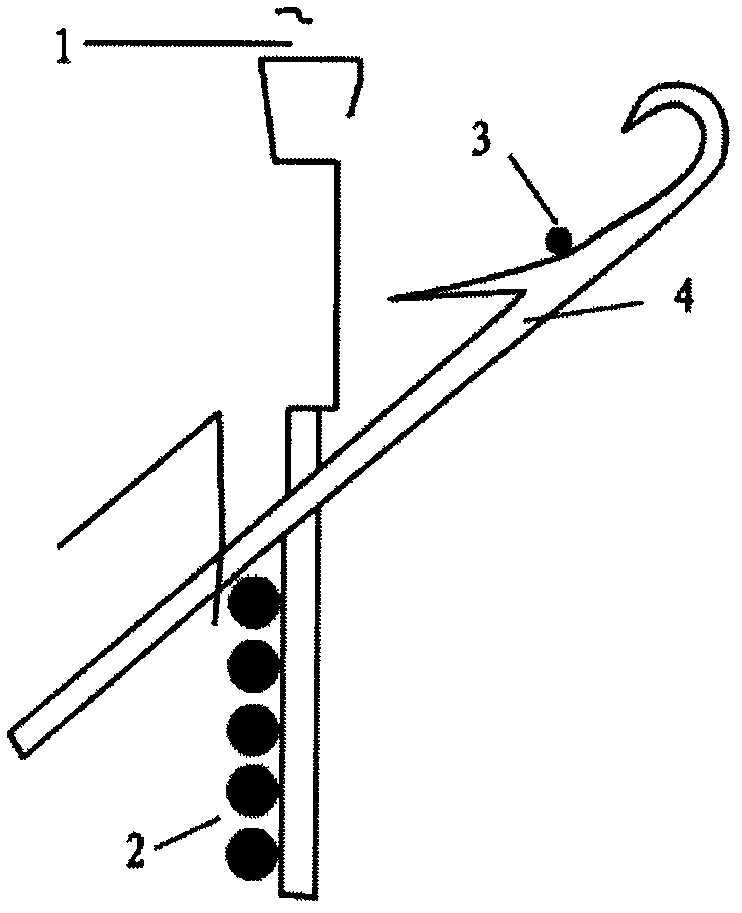

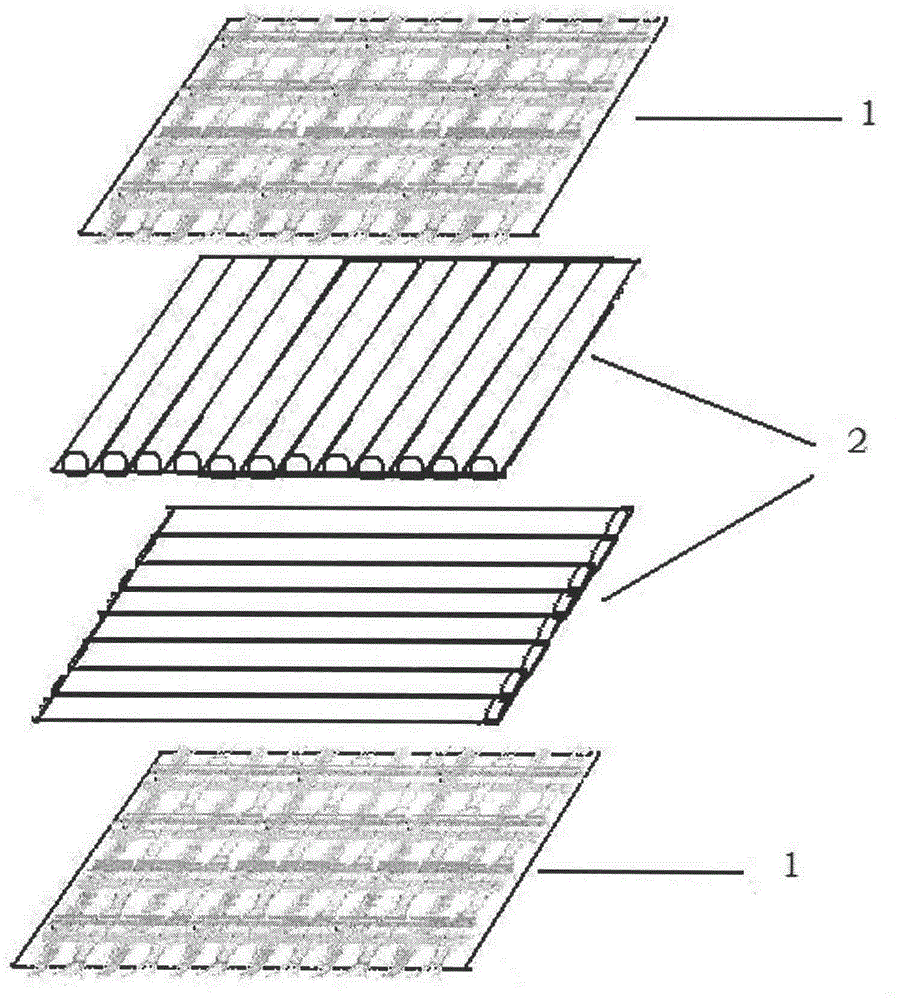

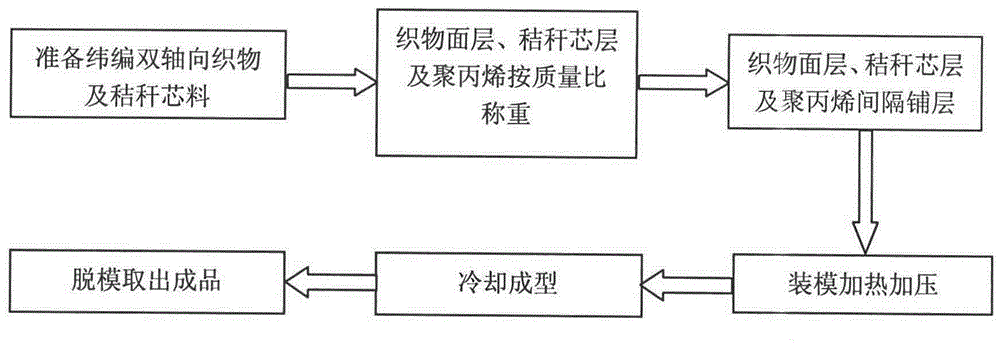

[0027] Example 1: With two layers of jute weft-knitted biaxial fabric as the upper and lower layers, two layers of jute weft-knitted biaxial fabric and straw core material and polypropylene staple fiber are prepared by hot pressing according to the ratio of mass ratio 1:1. High-quality composite material plate, the temperature range of hot pressing is 60°C-195°C.

[0028] The jute weft-knitted biaxially knitted fabric and the straw core material are laminated with polypropylene staple fibers at intervals, and each layer of jute fabric and straw layer are covered with a layer of polypropylene staple fibers on both sides; the hot press is heated to 60 ° C, Place the jute fabric, straw and polypropylene staple fiber laid at intervals above on a hot press, raise the temperature to 100°C, pressurize to 3MPa, keep the pressure and raise the temperature to 160°C, heat it for 10 minutes, then heat it up to 195°C, keep it warm and hold the pressure for 30 minutes After that, let it coo...

Embodiment 2

[0029] Embodiment 2: take 2 layers of jute weft-knitted biaxial fabrics as the upper and lower layers, this fabric and 2 layers of straw core material and polypropylene short fibers are hot-pressed according to the ratio of mass ratio 1: 1.5 to prepare light-weight composite material plates, The temperature range of hot pressing is 60°C-195°C.

[0030] The jute weft-knitted biaxially knitted fabric and the straw core material are laminated with polypropylene staple fibers at intervals, and each layer of jute fabric and straw layer are covered with a layer of polypropylene staple fibers on both sides; the hot press is heated to 60 ° C, Place the jute fabric, straw and polypropylene staple fiber laid at intervals above on a hot press, raise the temperature to 100°C, pressurize to 3MPa, keep the pressure and raise the temperature to 160°C, heat it for 10 minutes, then heat it up to 195°C, keep it warm and hold the pressure for 30 minutes After that, let it cool down to room tempe...

Embodiment 3

[0031] Embodiment 3: take 2 layers of jute weft-knitted biaxial fabrics as the upper and lower layers, this fabric and 2 layers of straw core material and polypropylene short fibers are hot-pressed according to the ratio of mass ratio 1: 2.3 to prepare lightweight composite material boards, The temperature range of hot pressing is 60°C-195°C.

[0032] The jute weft-knitted biaxially knitted fabric and the straw core material are laminated with polypropylene staple fibers at intervals, and each layer of jute fabric and straw layer are covered with a layer of polypropylene staple fibers on both sides; the hot press is heated to 60 ° C, Place the jute fabric, straw and polypropylene staple fiber laid at intervals above on a hot press, raise the temperature to 100°C, pressurize to 3MPa, keep the pressure and raise the temperature to 160°C, heat it for 10 minutes, then heat it up to 195°C, keep it warm and hold the pressure for 30 minutes After that, let it cool down to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com