Enhanced bi-component nanofiber porous membrane and preparation method thereof

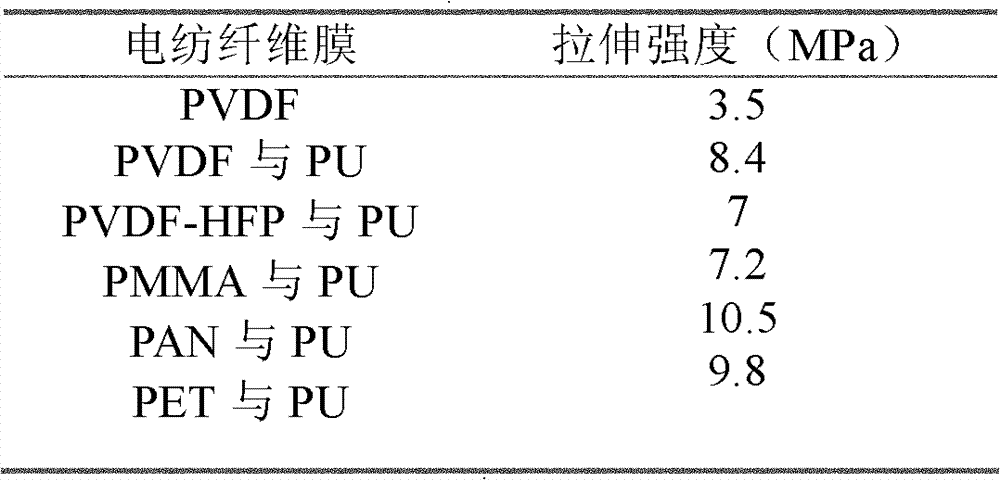

A nanofiber and bi-component fiber technology, applied in fiber processing, battery pack parts, filament/wire forming, etc., can solve the problems of insufficient battery strength, poor mechanical properties of nanofiber porous membrane, and battery self-closing performance Decrease and other issues, to achieve performance improvement, improve mechanical strength, improve ion permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

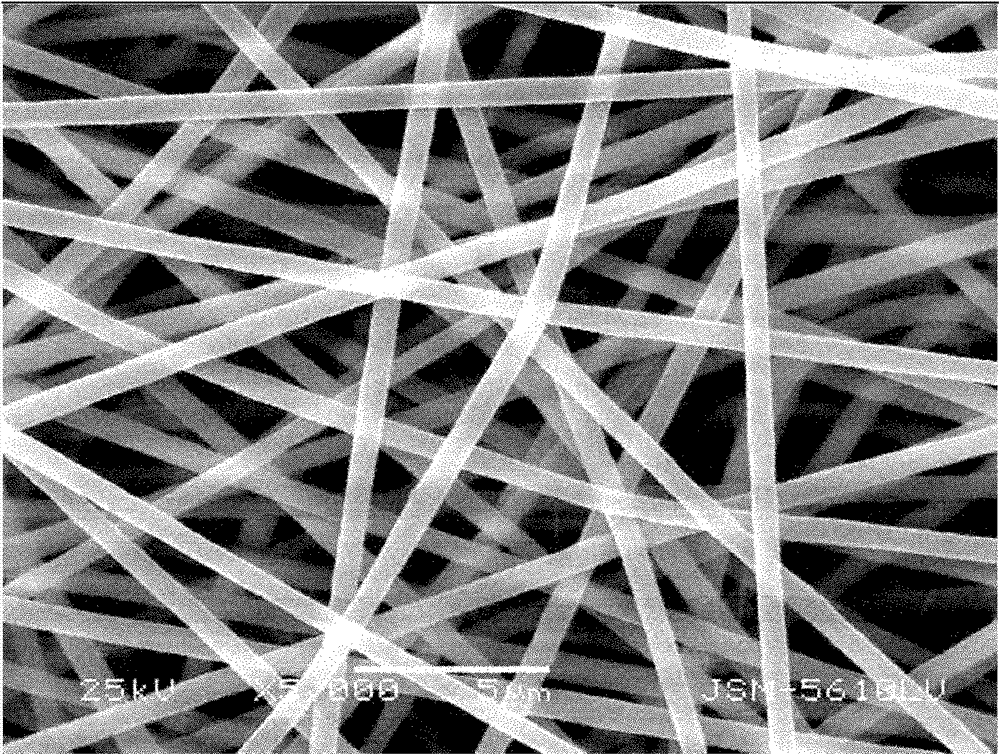

[0032] 1. Preparation of PVDF and PUR two-component fiber membrane

[0033] Dissolve polyvinylidene fluoride (PVDF) and PUR in a mixed solvent with a mass ratio of 92:8 of N,N-dimethylformamide (DMF) and acetone at a mass ratio of 5:5, and prepare a concentration of 12 wt%. solution, heated and stirred at 50-60°C for 10-20 minutes to achieve full dissolution. Inject the obtained solution into a syringe pump with an 8# flat needle, the needle is connected to the high-voltage output end, and the other end 15 cm away from the syringe pump is a metal roller electrode grounded with a high-voltage power supply as a collection device. Adjust the injection speed of the syringe pump to 0.3ml / h, and slowly increase the voltage to 15kv. The solution is sprayed from the needle of the syringe pump under the action of high pressure, and the film in the form of non-woven fabric is collected on the metal collecting device, and the obtained non-woven film is placed in a vacuum drying oven, an...

Embodiment 2

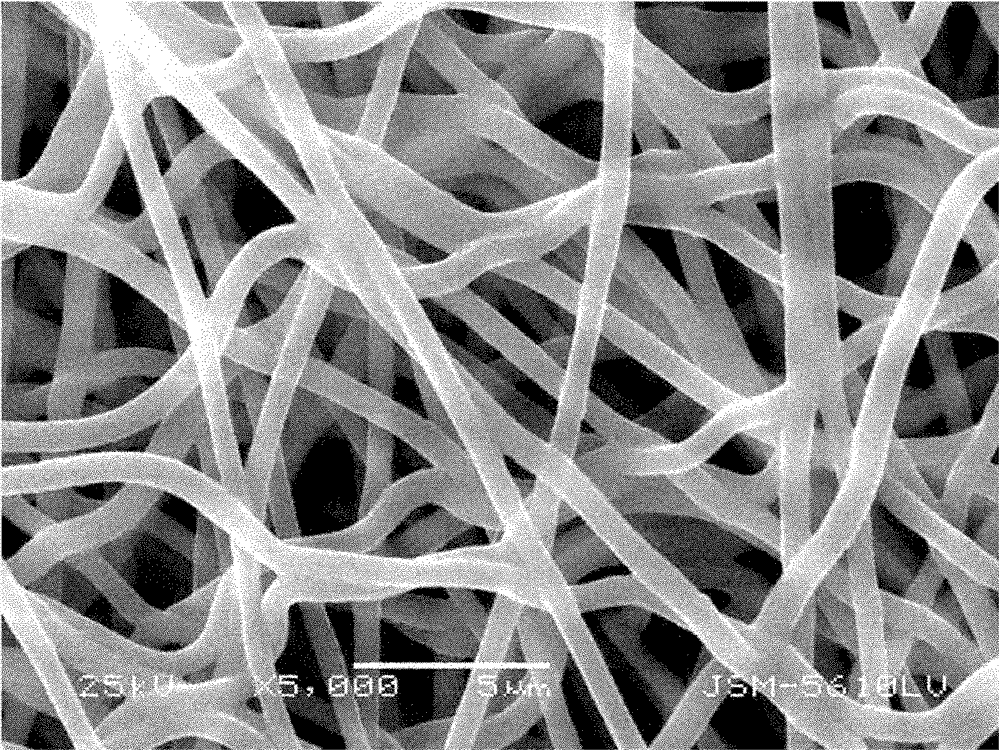

[0041] 1. Preparation of PVDF-HFP and PUR bicomponent fiber membrane

[0042] Polyvinylidene fluoride-hexachloropropylene (PVDF-HFP) and PUR were dissolved in a mixed solvent of N, N-dimethylformamide (DMF) and acetone with a mass ratio of = 8: 2 at a mass ratio of 92:8, Prepare a solution with a concentration of 16 wt%, and heat and stir at 50-60° C. for 10-20 minutes to achieve full dissolution. Inject the solution into a syringe pump with an 8# flat needle, the needle is connected to the high-voltage output end, and the other end 15cm away from the syringe pump is a metal roller electrode that is grounded to the high-voltage power supply as a collection device. Adjust the injection speed of the syringe pump to 0.47ml / h, and slowly increase the voltage to 15kv. The solution is sprayed from the needle of the syringe pump under the action of high pressure, and the film in the form of non-woven fabric is collected on the metal collecting device, and the obtained non-woven film...

Embodiment 3

[0050] 1. Preparation of PMMA and PUR two-component fiber membrane

[0051] Polymethyl methacrylate (PMMA) and PUR are dissolved in the mixed solvent of N, N-dimethylformamide (DMF) and toluene mass ratio = 6: 4 according to the mass ratio = 92: 8, and the concentration is prepared as 20wt% solution was stirred at room temperature for 24 hours to achieve full dissolution. Inject the solution into a syringe pump with an 8# flat needle, the needle is connected to the high-voltage output end, and the other end 18cm away from the syringe pump is a metal roller electrode grounded with a high-voltage power supply as a collection device. Adjust the injection speed of the syringe pump to 0.2ml / h, and slowly increase the voltage to 15kv. The solution is sprayed from the needle of the syringe pump under the action of high pressure, and the film in the form of non-woven fabric is collected on the metal collecting device, and the obtained non-woven film is placed in a vacuum drying oven,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com