Method for preparing cross-linked collagen/chitosan tissue engineering porous support in one-step freeze-drying mode

A porous scaffold and tissue engineering technology, which is applied in the field of preparing cross-linked collagen/chitosan tissue engineering porous scaffold by one-time freeze-drying, can solve the problem of unfavorable collagen/chitosan porous scaffold large-scale preparation process stabilization, unfavorable collagen /The industrial production of chitosan porous scaffolds, large batch quality differences and other issues, to achieve the effect of large-scale preparation, avoiding scaffold collapse and microstructure damage, and stable scaffold performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] A method for preparing a cross-linked collagen / chitosan tissue engineering porous scaffold by freeze-drying once, comprising the following steps:

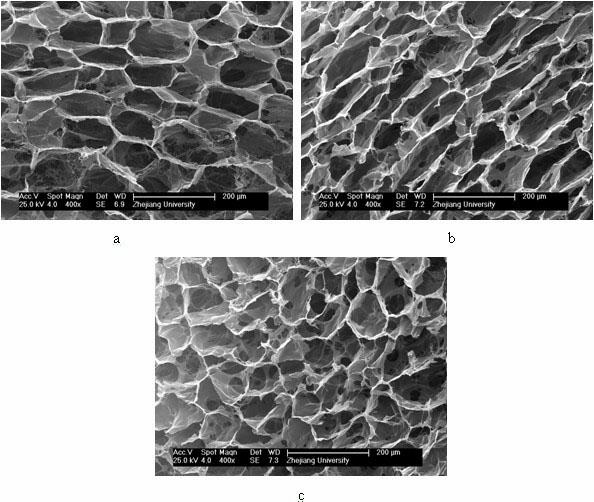

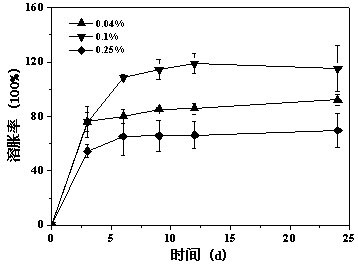

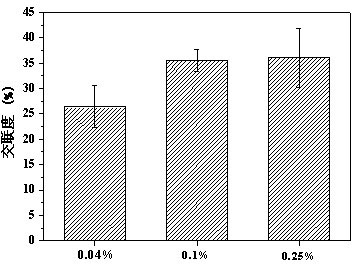

[0026] (1) Prepare beef tendon collagen solution and chitosan solution with a mass concentration of 0.5% in acetic acid solution, mix the beef tendon collagen solution and chitosan solution at a volume ratio of 9:1, and stir evenly to obtain beef tendon collagen / chitosan mixed swelling solution. Inject glutaraldehyde (GA) solution with a mass concentration of 2.5% into the mixed swelling solution to make the cross-linking concentrations respectively 0.04%, 0.1%, and 0.25%, and then at 37 oC The reaction was stirred for 4 hours. Inject the reacted bovine tendon collagen / chitosan mixed swelling solution into the mold at -20 oC After freezing for 2 hours, lyophilize to obtain a cross-linked bovine tendon collagen / chitosan porous scaffold. The cross-linking concentration refers to the mass concentration of glutaraldehyde i...

example 2

[0033] A method for preparing a cross-linked collagen / chitosan tissue engineering porous scaffold by freeze-drying once, comprising the following steps:

[0034] (1) Prepare collagen solution and chitosan solution with a mass concentration of 0.5% in acetic acid solution, mix the collagen solution and chitosan solution at a volume ratio of 9:1, and stir evenly to obtain collagen / chitosan Sugar mixed swelling solution. Inject the glutaraldehyde solution of mass concentration 2.5% in this mixed swelling liquid, make cross-linking concentration be 0.04%, then at 37 oC The reaction was stirred for 4 hours. Inject the reacted collagen / chitosan mixed swelling solution into the mold at -20 oC After freezing for 2 hours, lyophilize to obtain a cross-linked collagen / chitosan porous scaffold. The cross-linking concentration refers to the mass concentration of glutaraldehyde in the mixed swelling solution, using the formula 2.5% × V GA = C×(V GA +V 1 ) calculation, where V GA Re...

example 3

[0037] A method for preparing a cross-linked collagen / chitosan tissue engineering porous scaffold by freeze-drying once, comprising the following steps:

[0038] (1) Prepare fish skin collagen solution and chitosan solution with a mass concentration of 0.5% in hydrochloric acid solution, mix the fish skin collagen solution and chitosan solution at a volume ratio of 9:1, and stir evenly to obtain fish skin collagen / chitosan mixed swelling solution. Inject the glutaraldehyde solution of mass concentration 2.5% in this mixed swelling liquid, make cross-linking concentration be 0.1%, then in 37 oC The reaction was stirred for 4 hours. Inject the reacted fish skin collagen / chitosan mixed swelling solution into the mold at -20 oC After freezing for 3 hours, freeze-dry to obtain a cross-linked fish skin collagen / chitosan porous scaffold. The cross-linking concentration refers to the mass concentration of glutaraldehyde in the mixed swelling solution, using the formula 2.5% × V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com