Porous elastic polyvinyl alcohol/bacterial nano-cellulose composite hydrogel tube, as well as preparation method and application of composite hydrogel tube

A technology of nanocellulose and composite hydrogel, which is applied in medical science, prosthesis, surgery, etc., can solve the problems of restricting the application of medical materials and the lack of elasticity of tubular materials, and achieve the advantages of adhesion and proliferation, low cost, and good quality. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

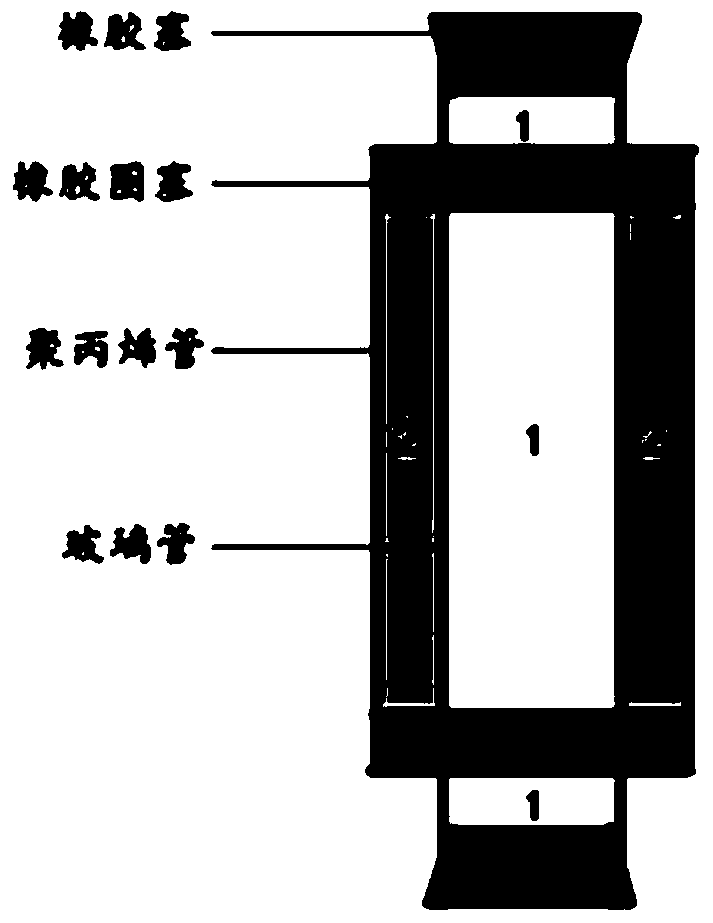

[0037] (1) Bacterial nanocellulose hydrogel tube pretreatment

[0038] Fix a bacterial nanocellulose hydrogel tube with an inner diameter of 3mm, an outer diameter of 5mm, and a length of 50mm to the outer wall of a glass tube with an inner diameter of 2mm and an outer diameter of 3mm, soak it in a solution with a NaOH concentration of 1% at 80°C for 4h, and then use it repeatedly Wash with ultrapure water until the endotoxin content is below 0.25 EU / g.

[0039] (2) Preparation of polyvinyl alcohol solution

[0040] Weigh 10g of polyvinyl alcohol (Mw=1750±50) into a blue-capped bottle filled with 70g of ultrapure water, tighten the cap and place in a shaking water bath at 95°C until completely dissolved, then add 20g of absolute ethanol, and tighten the bottle Cover and continue shaking in a water bath until a uniform solution is formed, take it out and let it cool down to room temperature for later use.

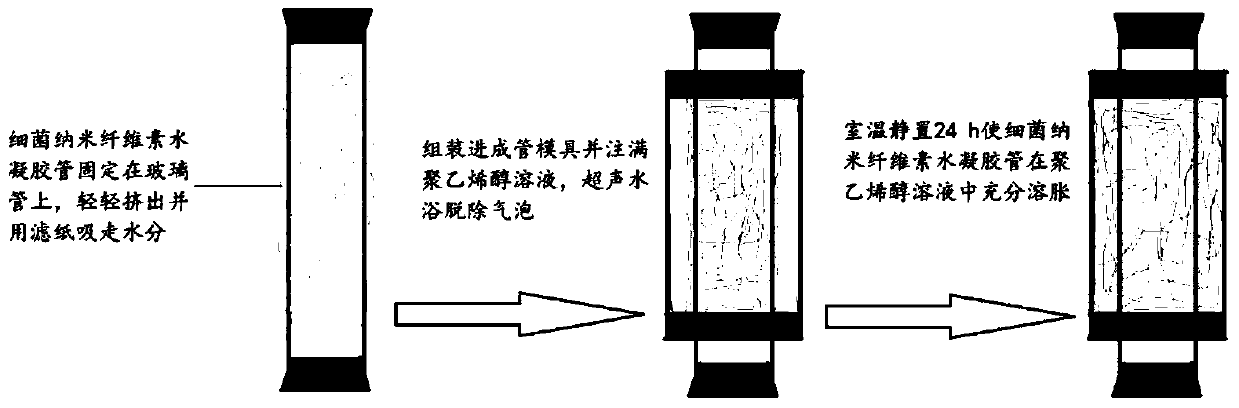

[0041] (3) Bacterial nanocellulose hydrogel tube combined with polyvi...

Embodiment 2

[0046] (1) Bacterial nanocellulose hydrogel tube pretreatment

[0047] Fix a bacterial nanocellulose hydrogel tube with an inner diameter of 6mm, an outer diameter of 8mm, and a length of 50mm to the outer wall of a glass tube with an inner diameter of 5mm and an outer diameter of 6mm, soak it in a 1% NaOH solution at 80°C for 4h, and then repeatedly wash it with a supernatant. Wash with pure water until the endotoxin content is below 0.25 EU / g.

[0048] (2) Preparation of polyvinyl alcohol solution

[0049] Weigh 10g of polyvinyl alcohol (Mw=1750±50) and 10g of NaCl into a blue cap bottle filled with 60g of ultrapure water, tighten the cap and place in a shaking water bath at 95°C until completely dissolved, then add 20g of absolute ethanol, Tighten the bottle cap and continue shaking in the water bath until a uniform solution is formed, take it out and let it cool down to room temperature for later use.

[0050] (3) Bacterial nanocellulose hydrogel tube combined with polyv...

Embodiment 3

[0055] (1) Bacterial nanocellulose hydrogel tube pretreatment

[0056] Fix a bacterial nanocellulose hydrogel tube with an inner diameter of 6 mm, an outer diameter of 8 mm, and a length of 50 mm on the outer wall of the glass tube, soak it in 1% NaOH solution at 80°C for 4 hours, and then wash it repeatedly with ultrapure water until the endotoxin content is reached. Below 0.25EU / g. (2) Preparation of polyvinyl alcohol solution

[0057] Weigh 15g of polyvinyl alcohol (1750±50) into a blue cap bottle filled with 65g of ultrapure water, tighten the cap and place in a 95°C shaking water bath until completely dissolved, then add 20g of absolute ethanol, tighten the cap to continue Shake in a water bath until a uniform solution is formed, take it out and let it cool down to room temperature for later use.

[0058] (3) Preparation of polyvinyl alcohol hydrogel tubes

[0059] Fill the inner cavity of a glass tube with an outer diameter of 6 mm and a wall thickness of 1 mm with ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com