Preparation method of porous titanium and titanium alloy

A technology of titanium alloy and porous titanium, which is applied in the field of preparation of porous titanium and titanium alloy, to achieve the effect of meeting the requirements of mechanical properties, simple preparation process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

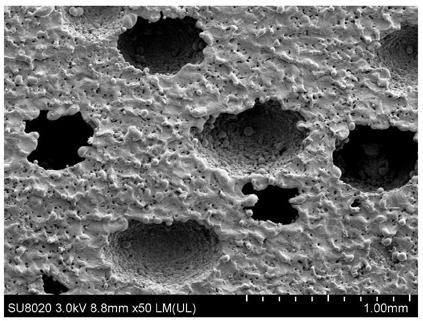

[0029] Concretely, the preparation method of porous titanium and titanium alloy comprises the following steps:

[0030] A, stearic acid, binding agent and titanium raw material are mixed uniformly to obtain a mixture; the titanium raw material is titanium powder, or a mixed powder of titanium and other metals;

[0031] B, the mixed material obtained in step A is compressed and molded, then dried to obtain a compact;

[0032] C. The compact is vacuum sintered and cooled to obtain porous titanium or porous titanium alloy.

[0033] The titanium raw material in the method of the present invention can adopt pure titanium powder, also can adopt the mixed powder of titanium and other metals; When it is the mixed powder of titanium and other metals, the mass content of other metals is no more than 20%, and other metals can be copper, molybdenum , iron, aluminum, silver, manganese, nickel, cobalt, niobium, zirconium, tantalum, etc. The present invention can adopt planetary ball mill ...

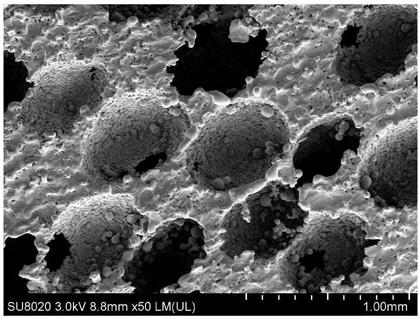

Embodiment 1

[0043] Weigh 50g of titanium powder, add absolute ethanol at 1.2mL / g of titanium powder, add grinding balls at a mass ratio of 10:1, mill on a planetary ball mill at 300 rpm for 2 hours, and dry to obtain titanium powder; 300-600μm spherical stearic acid and 0.08mL of 5% polyvinyl alcohol aqueous solution per gram of titanium powder are fully mixed, and pure titanium powder is added so that the mass ratio of stearic acid to titanium powder is 40%: 60% , and mix evenly; then put the mixture into a mold, press uniaxially at a pressure of 165 MPa, hold the pressure for 3 minutes, and then put it in a constant temperature drying oven at 60 ° C for 10 hours; put the dried compact into a vacuum In the sintering furnace, the vacuum degree is 10 -1 ~10 -3 Under Pa, heat up to 200°C at a rate of 5°C / min, hold for 1 hour, then heat up to 500°C at a rate of 5°C / min, hold for 2 hours, then heat up to 800°C at a rate of 5°C / min, and hold for 30 minutes. Finally, the temperature was raise...

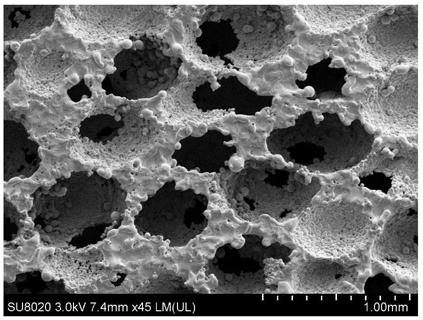

Embodiment 2

[0045] Weigh a total of 50g according to the mass percentage of copper powder and titanium powder as 5%: 95%, add absolute ethanol at 1.2mL / g powder, add grinding balls at a mass ratio of 10:1, and grind on a planetary ball mill at 300 rpm Min ball milling for 2 hours, and after drying, titanium-copper mixed powder was obtained; spherical stearic acid with a size of 300-600 μm was added to 0.08 mL of 5% polyvinyl alcohol aqueous solution per gram of titanium-copper mixed powder, and the titanium-copper mixed powder was added. Mix the powder so that the mass ratio of stearic acid and titanium-copper mixed powder is 40%: 60%, and mix evenly; then put the mixture into a mold, press it under a pressure of 165MPa through uniaxial pressing, keep the pressure for 3min, and then put Put it into a constant temperature drying oven and dry it at 60°C for 10 hours; put the dried compact into a vacuum sintering furnace, and put it in a vacuum degree of 10 -1 ~10 -3 Under Pa, heat up to 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com