Putty type silicone rubber composition and preparation method and application thereof

A silicone rubber composition, putty-type technology, applied in the field of polymer materials, can solve problems such as unfavorable application, catalyst poisoning, plasticizer carcinogenic risks, etc., achieve excellent mechanical strength, improve elongation at break and elasticity, and avoid material Hard and brittle and not resistant to acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

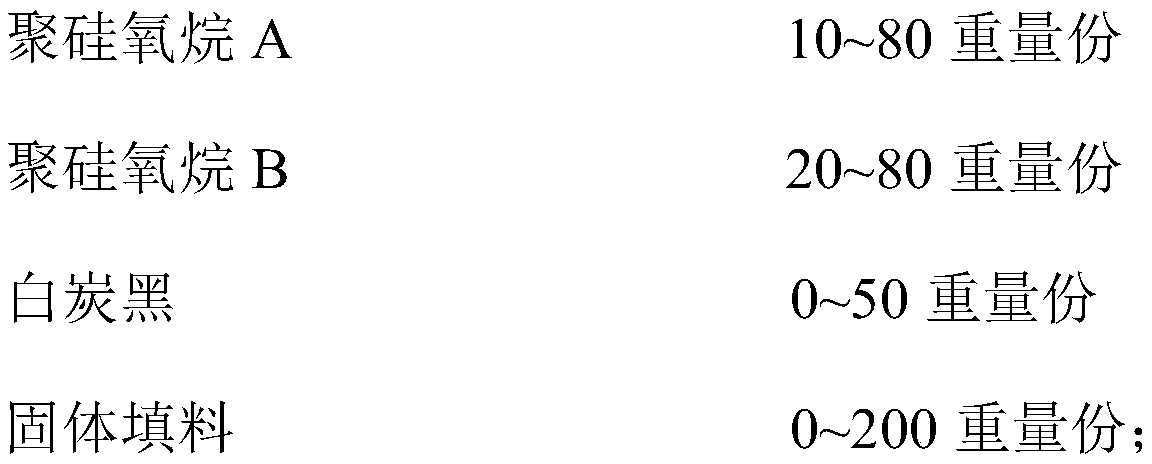

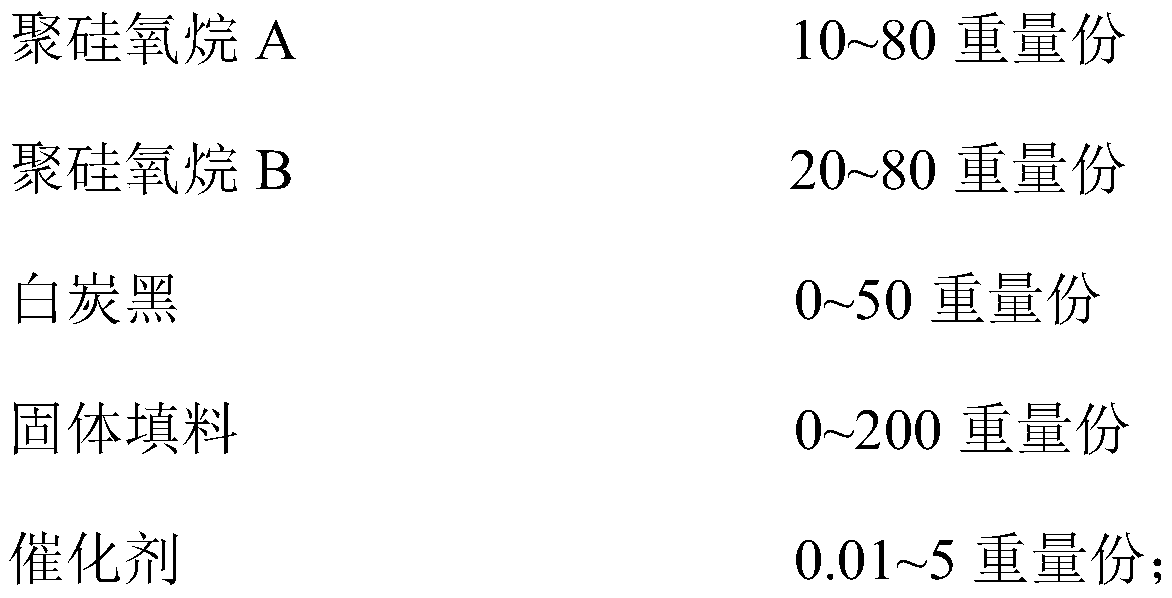

[0101] This embodiment provides a kind of putty type silicone rubber composition, and its preparation raw material comprises the components as shown in Table 1:

[0102] Table 1

[0103]

[0104]

[0105] Among them, polysiloxane A is vinyl silicone oil, the mass percentage of vinyl chains is 2wt%, and the dynamic viscosity is 200CPS; polysiloxane B is vinyl raw rubber, and the mass percentage of vinyl chains is is 0.03wt%, and the number-average molecular weight is 700000g / mol; polysiloxane C is hydrogen-containing silicone oil, the mass percentage of hydrogen is 0.2wt%, and the dynamic viscosity is 20CPS; polysiloxane D is methyl silicone oil, dynamic The viscosity is 50CPS; the silica is fumed silica; the solid filler is 3000 mesh talcum powder; the structure control agent is polyhydroxy silicone oil; the catalyst is platinum catalyst. The mass ratio of the crosslinking component and the catalytic component is 1:1.

[0106] The preparation method includes the follow...

Embodiment 2

[0114] This embodiment provides a kind of putty type silicone rubber composition, and its preparation raw material comprises the components as shown in Table 2:

[0115] Table 2

[0116] raw material Cross-linking component Catalytic component Polysiloxane A 20 parts by weight 20 parts by weight Polysiloxane B 25 parts by weight 25 parts by weight Polysiloxane C 7.5 parts by weight 0 Polysiloxane D 0.5 parts by weight 0.5 parts by weight Silica 10 parts by weight 10 parts by weight solid filler 50 parts by weight 50 parts by weight structured control agent 1 part by weight 1 part by weight Auxiliary 0.1 parts by weight 0.1 parts by weight catalyst 0 0.05 parts by weight

[0117] Among them, polysiloxane A is vinyl silicone oil, the mass percentage of vinyl chain link is 1.1wt%, and the dynamic viscosity is 500CPS; Polysiloxane B is vinyl raw rubber, and the mass percentage of vinyl cha...

Embodiment 3

[0126] This embodiment provides a putty type silicone rubber composition, and its preparation raw materials include components as shown in Table 3:

[0127] table 3

[0128] raw material Cross-linking component Catalytic component Polysiloxane A 15 parts by weight 15 parts by weight Polysiloxane B 30 parts by weight 30 parts by weight Polysiloxane C 5 parts by weight 0 Silica 30 parts by weight 30 parts by weight structured control agent 7.5 parts by weight 7.5 parts by weight catalyst 0 0.1 parts by weight

[0129] Among them, polysiloxane A is vinyl silicone oil, the mass percentage of vinyl chain link is 1.1wt%, and the dynamic viscosity is 500CPS; Polysiloxane B is vinyl raw rubber, and the mass percentage of vinyl chain link is The content is 0.5wt%, the number-average molecular weight is 550000g / mol; the polysiloxane C is mercaptopropyl silicone oil, the mole percentage of mercapto chain link is 50%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com