Three-dimensional-structured silk fibroin/hydroxyapatite composite stent and preparation method thereof

A technology of hydroxyapatite and silk fibroin, which is applied in medical science, prosthesis, additive processing, etc., can solve the problems of low pore connectivity of scaffolds, difficult to control the shape and structure, and difficult to remove pore-forming materials. Beneficial for osteogenic induction, good pore connectivity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

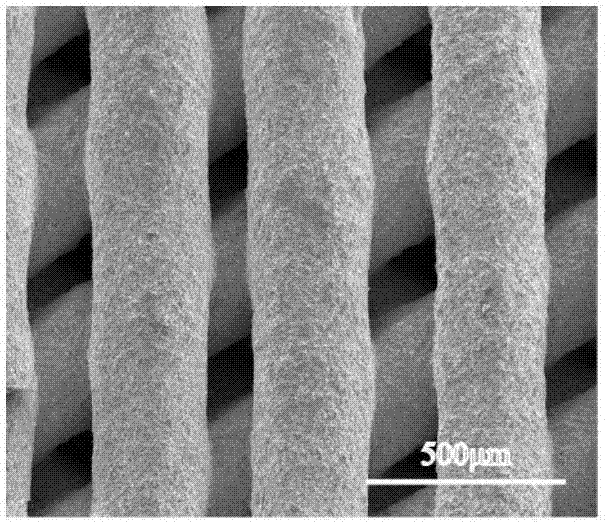

Embodiment 1

[0045] A silk fibroin / hydroxyapatite composite scaffold with a three-dimensional structure is prepared by a method comprising the following steps:

[0046] (1) Remove silkworm chrysalis from silkworm cocoons and clean up debris on the surface of silkworm cocoons

[0047] Dip 4.3g silkworm cocoons into 500ml of Na with a concentration of 0.5g / L 2 CO 3 In the aqueous solution, degumming was carried out by boiling in water at 100°C for 60 minutes, the silk obtained after degumming was taken out, washed 3 times with deionized water, and then vacuum-dried at 60°C for 24 hours to obtain silk, which was dried and stored at room temperature for later use;

[0048] (2), preparation of silk solution

[0049] First, 11.10g CaCl 2 , 9.20gCH 3 CH 2 OH and 14.4g deionized water are calculated by molar ratio, that is, CaCl 2 :CH 3 CH 2 OH: Deionized water is mixed at a ratio of 1:2:8 to obtain a ternary mixed solution;

[0050] Then dissolve all the silk obtained in step (1) in the ...

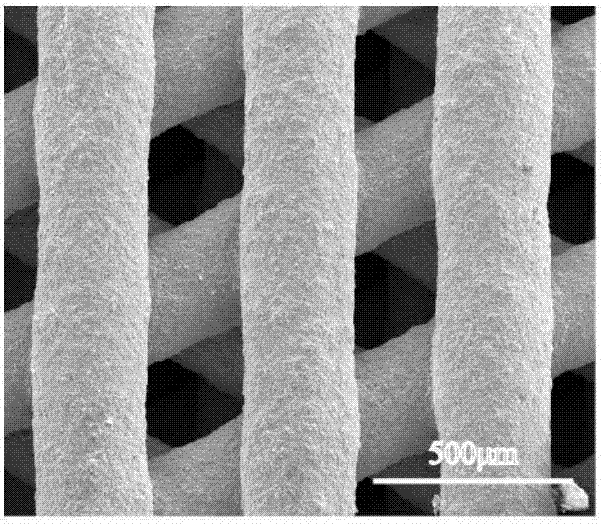

Embodiment 2

[0066] A silk fibroin / hydroxyapatite composite scaffold with a three-dimensional structure is prepared by a method comprising the following steps:

[0067] (1) Remove silkworm chrysalis from silkworm cocoons and clean up debris on the surface of silkworm cocoons

[0068] Dip 4.3g silkworm cocoons into 500ml of Na with a concentration of 0.5g / L 2 CO 3 In the aqueous solution, degumming was carried out by boiling in water at 100°C for 60 minutes, the silk obtained after degumming was taken out, washed 3 times with deionized water, and then vacuum-dried at 60°C for 24 hours to obtain silk, which was dried and stored at room temperature for later use;

[0069] (2), preparation of silk solution

[0070] First, 11.10g CaCl 2 , 9.20gCH 3 CH 2 OH and 14.4g deionized water are calculated by molar ratio, that is, CaCl 2 :CH 3 CH 2 OH: Deionized water is mixed at a ratio of 1:2:8 to obtain a ternary mixed solution;

[0071] Then dissolve all the silk obtained in step (1) in the ...

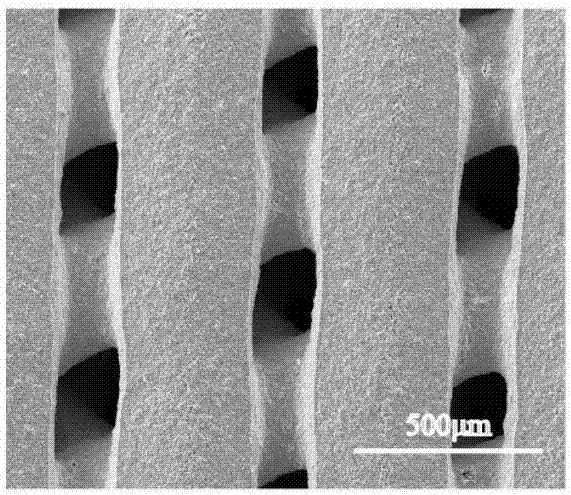

Embodiment 3

[0087] A silk fibroin / hydroxyapatite composite scaffold with a three-dimensional structure is prepared by a method comprising the following steps:

[0088] (1) Remove silkworm chrysalis from silkworm cocoons and clean up debris on the surface of silkworm cocoons

[0089] Dip 4.3g silkworm cocoons into 500ml of Na with a concentration of 0.5g / L 2 CO 3 In the aqueous solution, degumming was carried out by boiling in water at 100°C for 60 minutes, the silk obtained after degumming was taken out, washed 3 times with deionized water, and then vacuum-dried at 60°C for 24 hours to obtain silk, which was dried and stored at room temperature for later use;

[0090] (2), preparation of silk solution

[0091] First, 11.10g CaCl 2 , 9.20gCH 3 CH 2 OH and 14.4g deionized water are calculated by molar ratio, that is, CaCl 2 :CH 3 CH 2 OH: Deionized water is mixed at a ratio of 1:2:8 to obtain a ternary mixed solution;

[0092] Then dissolve all the silk obtained in step (1) in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com