Novel gasification combustion device

A combustion device and a new type of technology, applied in the field of coal-fired furnaces, new gasification combustion devices, and boilers, can solve the problems of high manufacturing cost, troublesome maintenance and repair of gasification furnaces, and serious environmental pollution, etc., and improve energy utilization. , high environmental protection performance, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

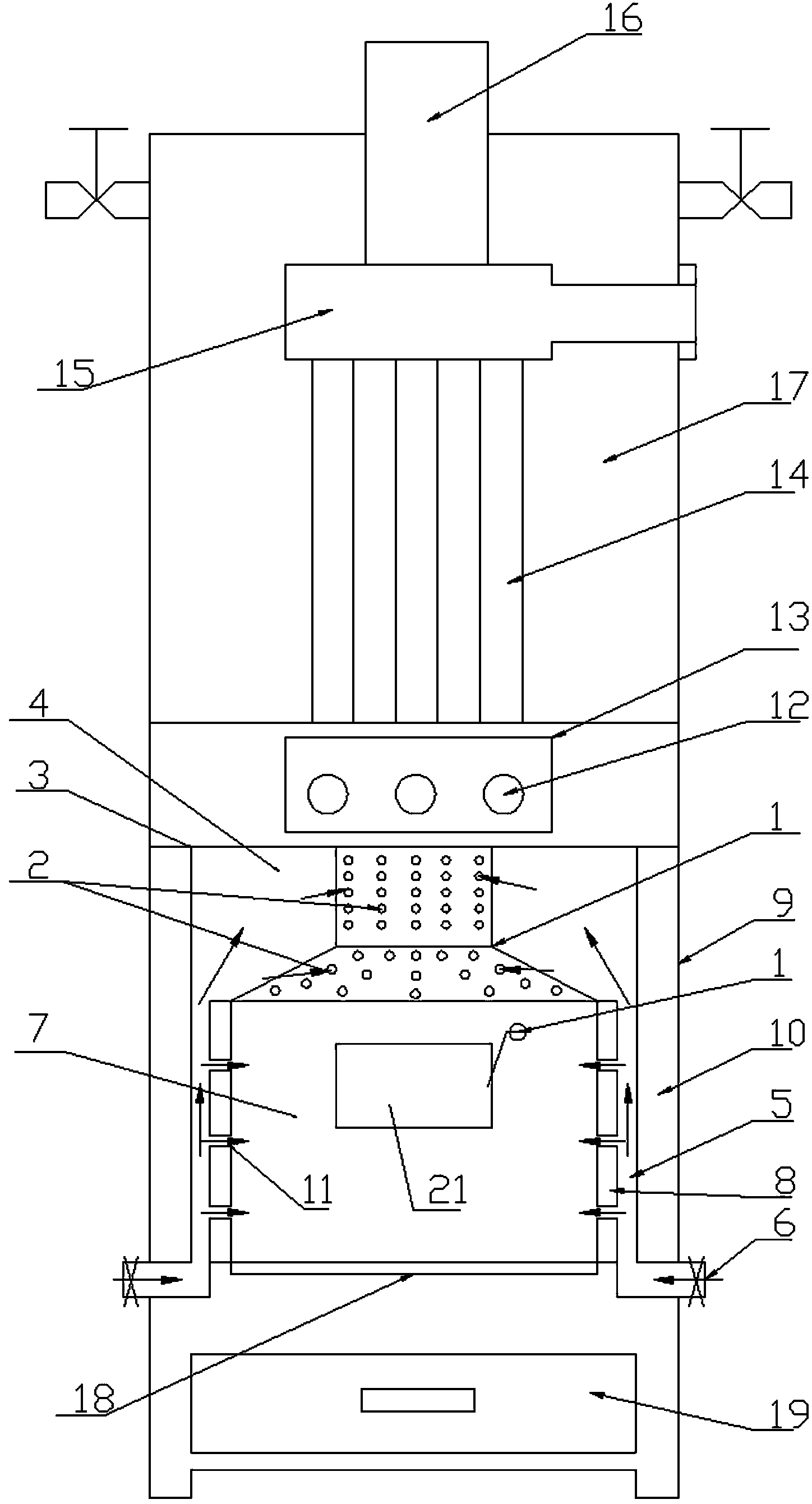

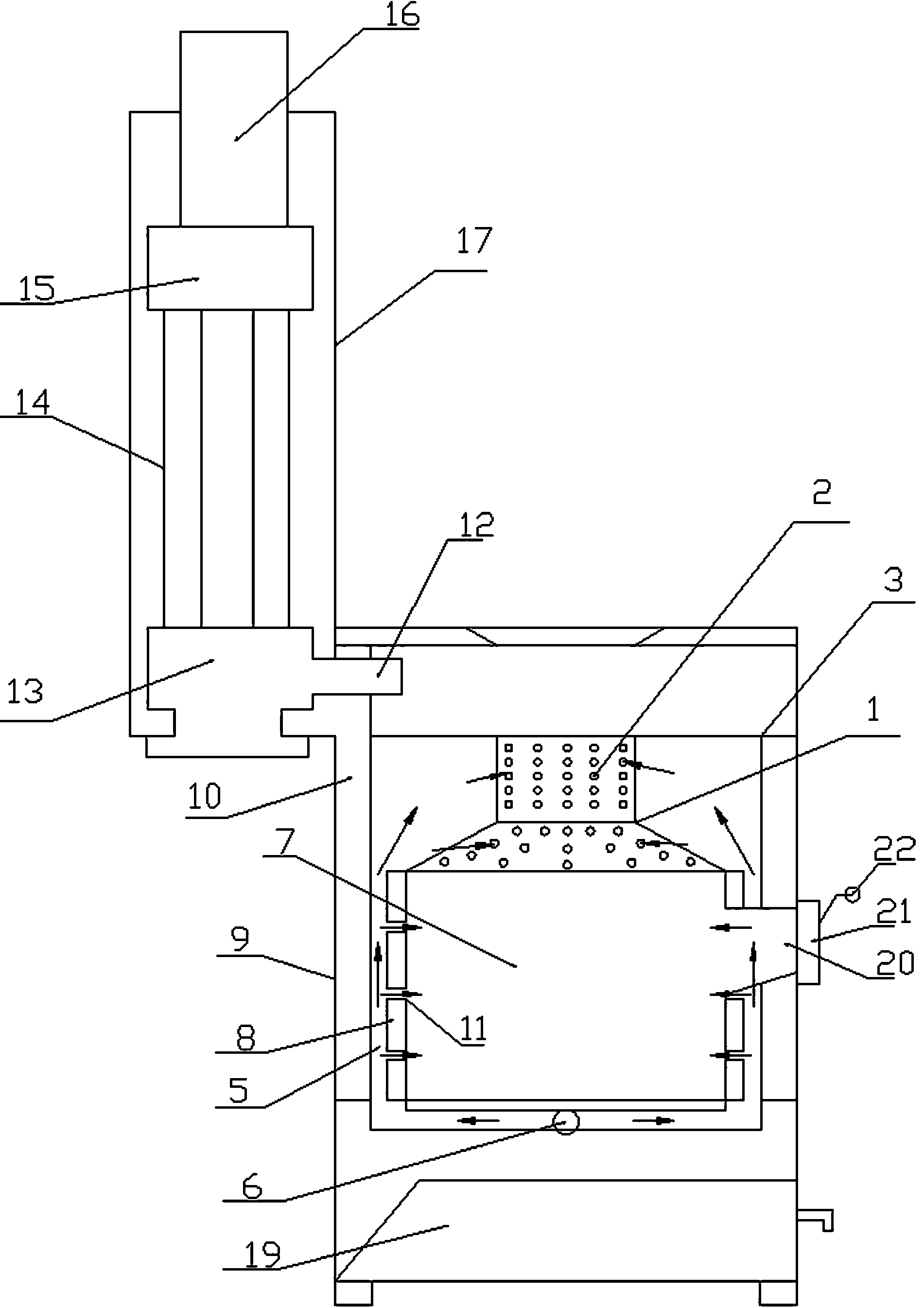

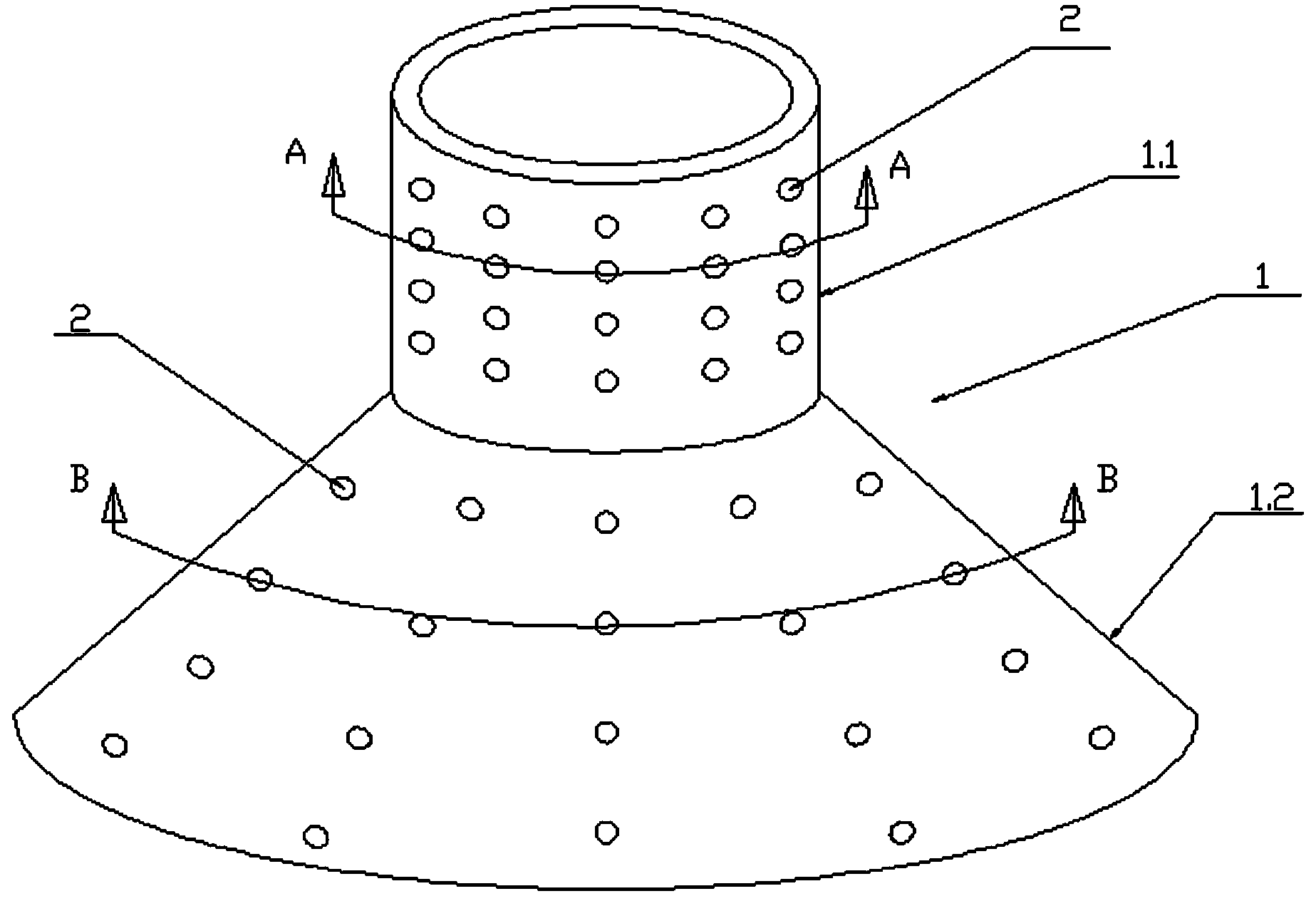

[0023] For ease of description, the novel gasification combustion device of the invention will be described in detail below in conjunction with the accompanying drawings.

[0024] like Figure 1 to Figure 5 As shown in , a new type of gasification combustion device includes a gasification cylinder 1, the surface of the gasification cylinder 1 is provided with a gasification hole 2, and the direction of the gasification hole 2 can form a gasification cylinder 1 inside. Swirling air flow; the gasification cylinder 1 includes a first part 1.1 and a second part 1.2, the first part 1.1 is a straight cylindrical structure, the second part 1.2 is a trumpet-shaped structure with a large lower end and a small top end, and the top of the second part 1.2 is connected to the first part 1.1 Connected, the gasification cylinder has a small top and a large bottom structure, which is convenient to form an upward self-suction force. In addition, the size of the upper part becomes smaller, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com