Substrate integrated waveguide-based loaded type Ka-band horn antenna

A substrate integrated waveguide and horn antenna technology, applied in the directions of waveguide horns, antennas, antenna arrays, etc., can solve the problem of low gain of horn antennas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

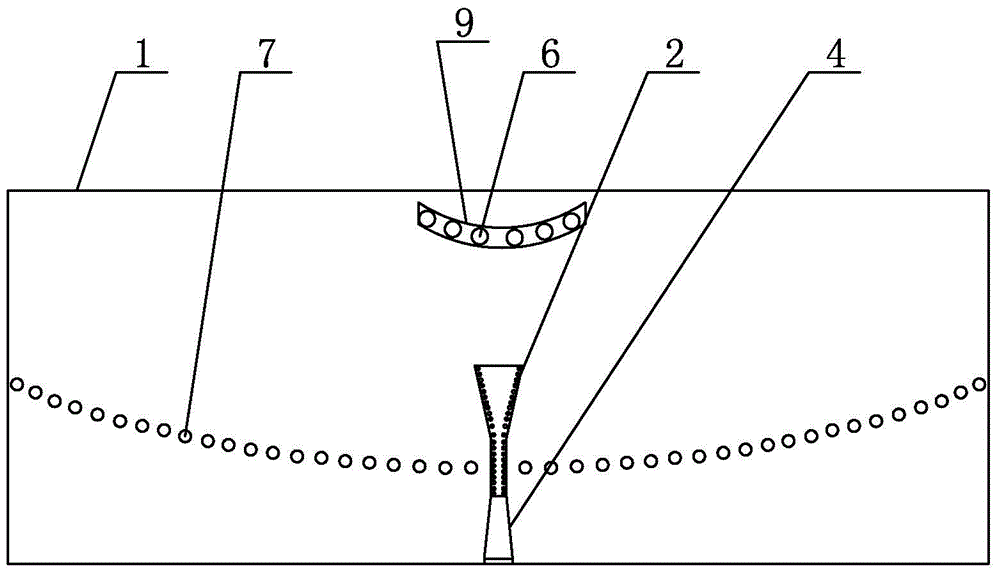

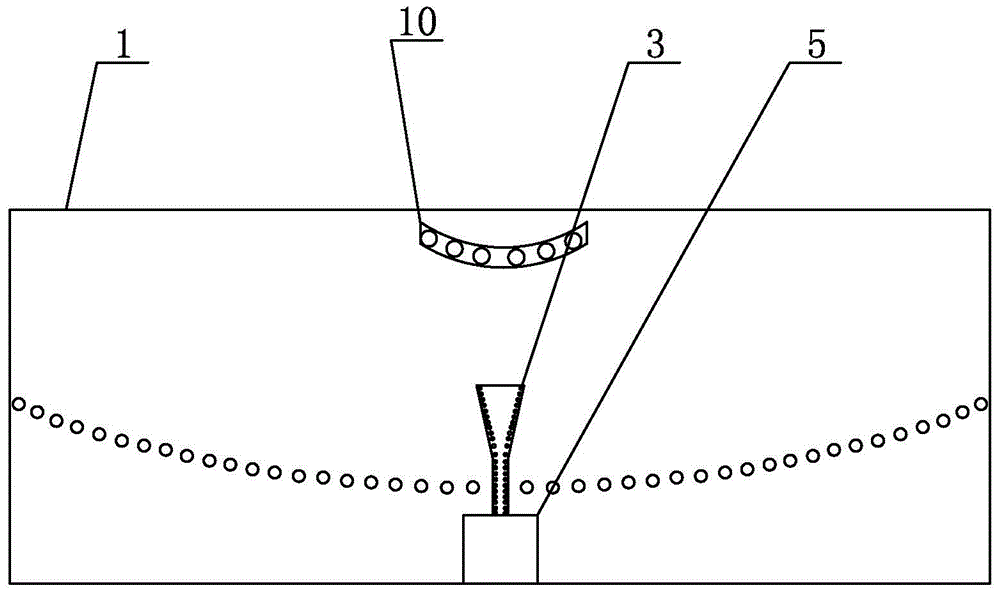

[0007] Specific implementation mode one: combine Figure 1 to Figure 4 This embodiment is described. The substrate-integrated waveguide-loaded Ka-band horn antenna described in this embodiment includes a dielectric substrate 1, a front horn structure 2, a rear horn structure 3, a front microstrip line 4, and a rear microstrip line 5. The dielectric substrate 1 is a rectangular plate. The upper metal layer 9 and the lower metal layer 10 are printed on the front and back of the dielectric substrate 1 respectively. The front speaker structure 2 is arranged in the middle and lower part of the front of the dielectric substrate 1, and the front speaker structure 2 is along the length direction. The center line of the dielectric substrate 1 is perpendicular to the center line along the length direction of the dielectric substrate 1, the lower end of the front speaker structure 2 is connected to the lower long side of the front surface of the dielectric substrate 1 through the front mi...

specific Embodiment approach 2

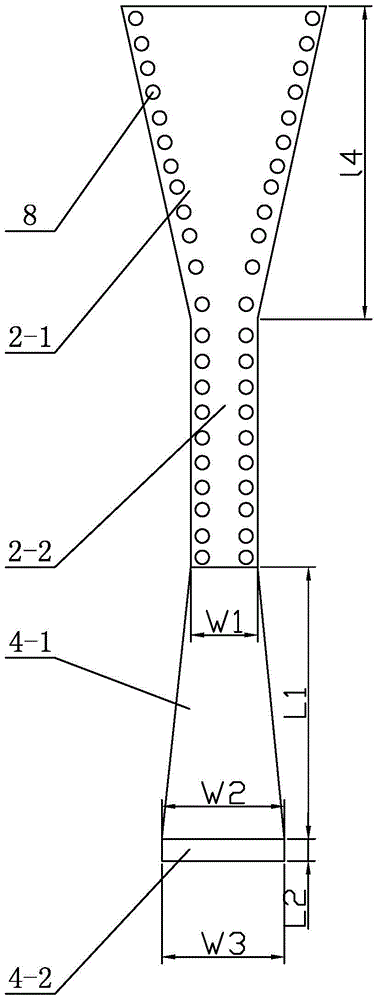

[0008] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, the front horn structure 2 of a loaded Ka-band horn antenna based on a substrate integrated waveguide described in this embodiment consists of a first inverted isosceles trapezoidal segment 2-1 and a first rectangular segment 2-2. It is connected sequentially from bottom to bottom, the short base of the first inverted isosceles trapezoidal segment 2-1 is connected to one short side of the first rectangular segment 2-2, and the other short side of the first rectangular segment 2-2 is connected to the front microstrip The upper end of the line 4 is connected, and the back speaker structure 3 is composed of the second inverted isosceles trapezoidal segment 3-1 and the second rectangular segment 3-2 sequentially connected from top to bottom, and the short bottom of the second inverted isosceles trapezoidal segment 3-1 The side is connected with a short side of the second recta...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the length of the dielectric substrate 1 of the loaded Ka-band horn antenna based on the substrate integrated waveguide described in this embodiment is 190 mm, the width of the dielectric substrate 1 is 74.5 mm, and the thickness of the dielectric substrate 1 is 3 mm. The relative dielectric constant of the dielectric substrate 1 is 4.4-4.6.

[0011] The technical effect of this embodiment is that: with such arrangement, the designed antenna can have a smaller structural size while satisfying the electrical specification. Other components and connections are the same as those in the first embodiment.

[0012] Specifically, the fourth method: combining Figure 1 to Figure 4 Describe this embodiment, the length L1 of the upper section 4-1 of the front microstrip line 4 of the loaded Ka-band horn antenna based on the substrate integrated waveguide described in this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com