Dual-frequency rotary joint used capable of realizing S single-frequency and X single-frequency transmission

A rotary joint, single-frequency technology, applied in the direction of electrical components, circuits, waveguide devices, etc., to achieve the effect of strong bearing capacity, low signal transmission loss, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

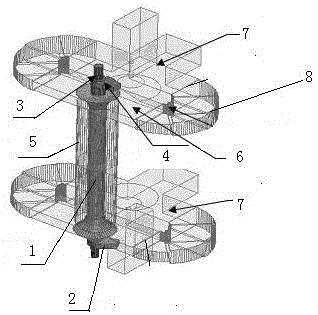

[0031] In this embodiment, a dual-frequency rotary joint for S single-frequency and X single-frequency transmission transmits radio frequency signals of S and X frequency bands at the same time in one joint, and two channels are designed for the joint to transmit S frequency band and X frequency band respectively the emission signal. During the design, the two-way rotary joints are designed separately. After the design of each joint is completed, the two-way joints are combined together, so that the whole rotary joint has the ability to transmit S and X frequency bands at the same time. Joint diagram as in figure 1 shown.

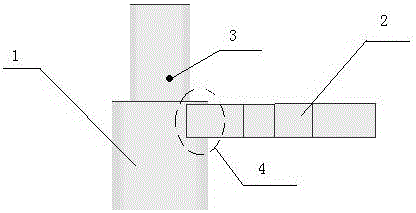

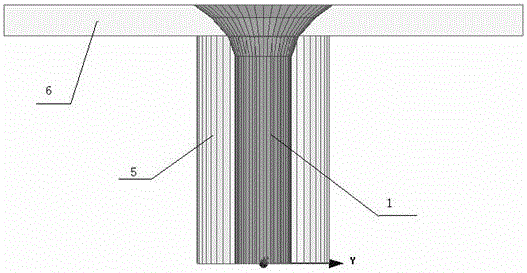

[0032] (1) Design and simulation of X-band rotary joints

[0033] The composition of the X-band joint mainly includes a circular waveguide 1, a rectangular waveguide 2, a short-circuit tube 3, and a coupling hole 4 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com