Mica-reinforced polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of composite materials, can solve the problems of general electrical insulation performance, affecting the degree of warpage, insufficient rigidity index, etc., and achieve the effect of high withstand voltage data, good insulation performance, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

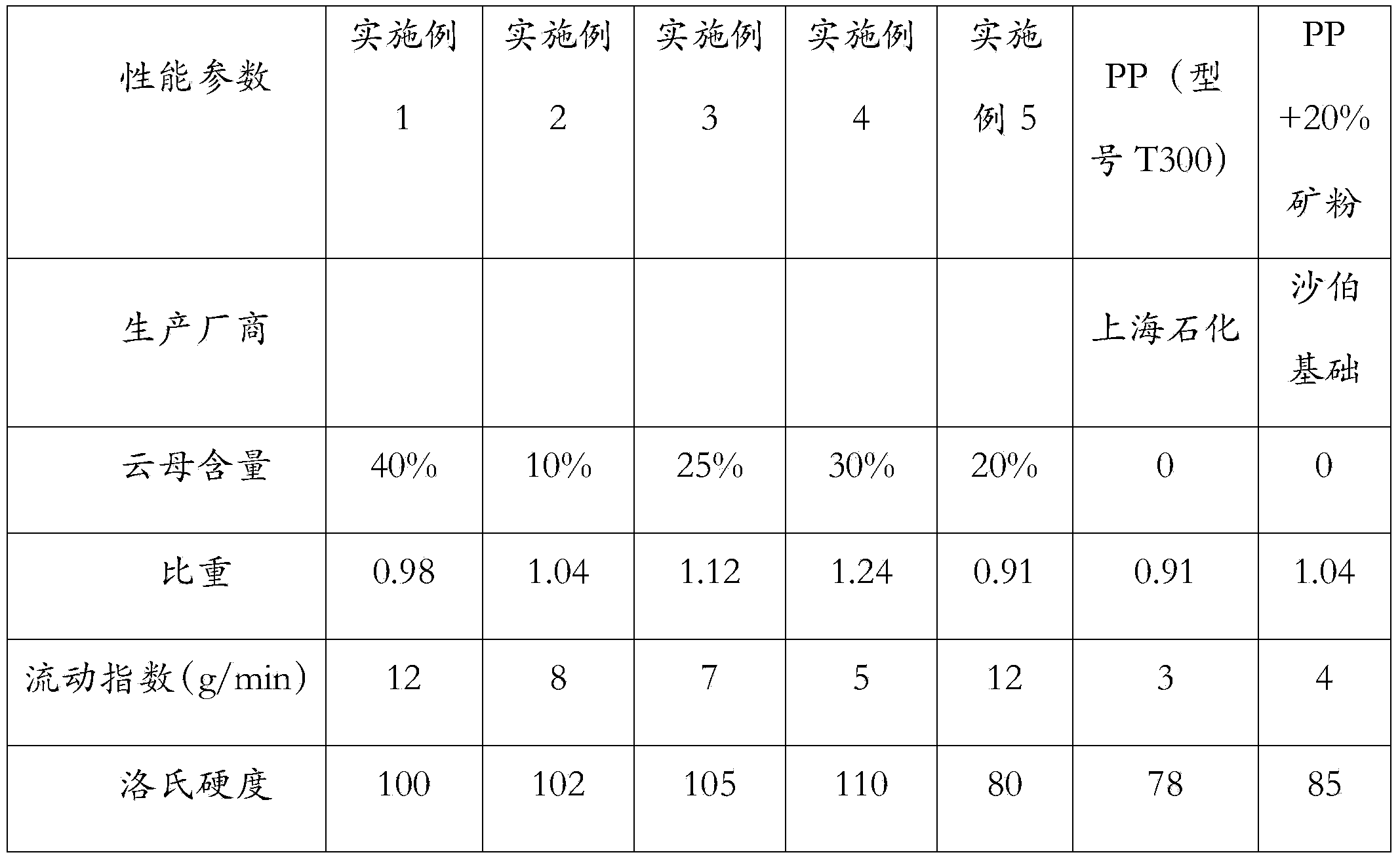

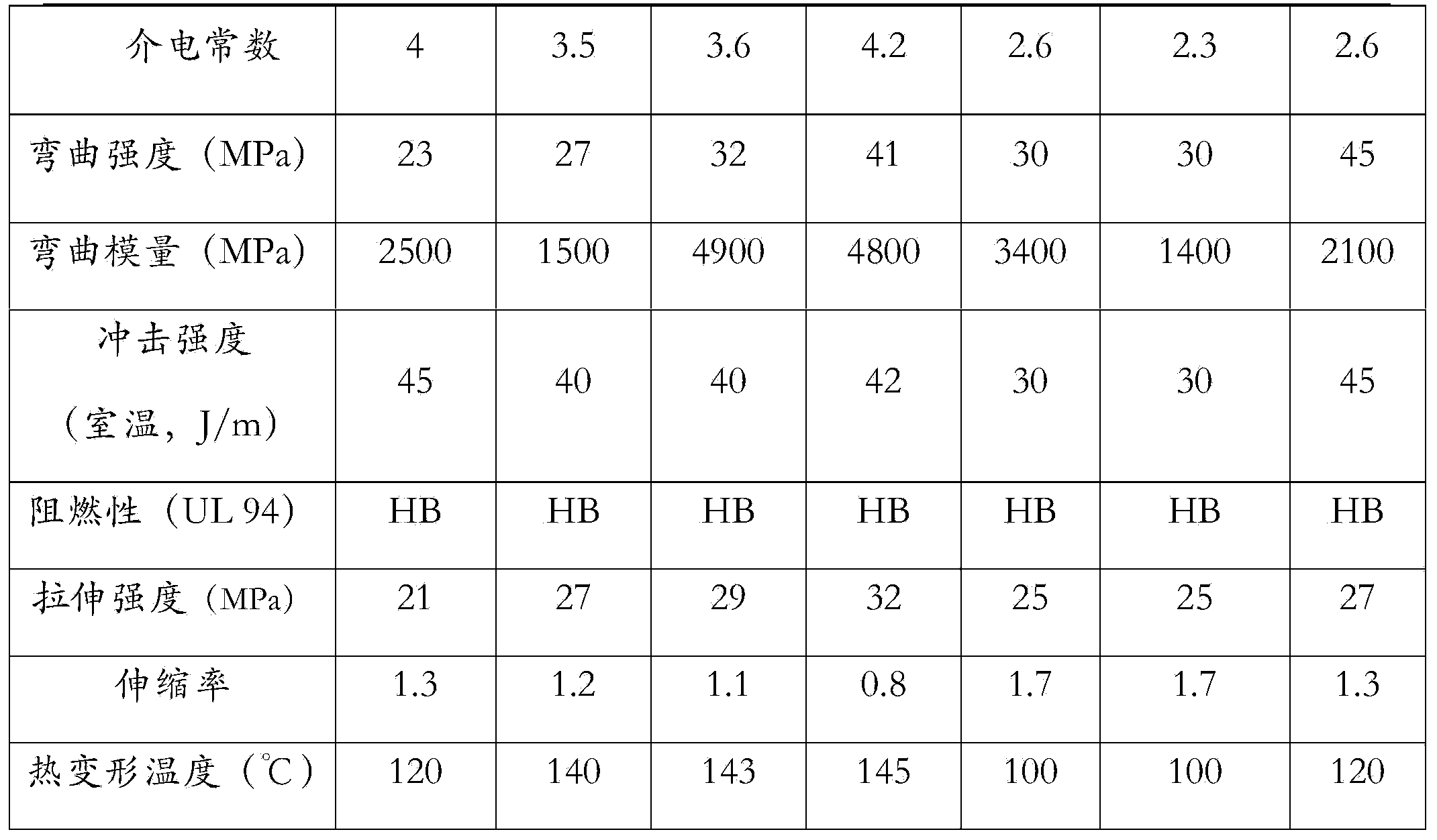

Examples

Embodiment 1

[0058] 1) Take 10kg of copolymerized polypropylene, 40kg of homopolypropylene, 40kg of mica powder, 9.5kg of compatibilizer and 0.5kg of antioxidant in a plastic cylinder and mix for 3 minutes, stirring and mixing evenly;

[0059] 2) Take out the raw material mixed in the above step 1), pour it into the feed port of the twin-screw extruder, extrude it at a temperature of 200°C and a speed of 330 rpm, and extrude it into a strip-shaped raw material ;

[0060] 3) The primary material obtained in the above step 2) is cooled in a water tank and in the air, and then cut into plastic particles by a pelletizer to obtain a mica-reinforced polypropylene composite material.

[0061] The color of the mica-reinforced polypropylene composite material obtained in the above step 3) is white or black.

Embodiment 2

[0063] 1) Mix 20kg of polypropylene copolymer, 65kg of homopolypropylene, 10kg of mica powder, 4.7kg of compatibilizer and 0.3kg of antioxidant in a plastic cylinder for 5 minutes, and mix well;

[0064] 2) Take out the raw materials mixed in the above step 1), pour them into the feed port of the twin-screw extruder, extrude them at a temperature of 220°C and a speed of 350 rpm, and extrude them into strip-shaped raw materials ;

[0065] 3) The primary material obtained in the above step 2) is cooled in a water tank and in the air, and then cut into plastic particles by a pelletizer to obtain a mica-reinforced polypropylene composite material.

[0066] The color of the mica-reinforced polypropylene composite material obtained in the above step 3) is white or black.

Embodiment 3

[0068] 1) Mix 15kg of polypropylene copolymer, 52.5kg of homopolypropylene, 25kg of mica powder, 7.1kg of compatibilizer and 0.4kg of antioxidant in a plastic cylinder for 7 minutes, and mix well;

[0069]2) Take out the raw materials mixed in the above step 1), pour them into the feed port of the twin-screw extruder, extrude them at a temperature of 240°C and a speed of 410 rpm, and extrude them into strip-shaped raw materials ;

[0070] 3) The primary material obtained in the above step 2) is cooled in a water tank and in the air, and then cut into plastic particles by a pelletizer to obtain a mica-reinforced polypropylene composite material.

[0071] The color of the mica-reinforced polypropylene composite material obtained in the above step 3) is white or black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com