Method for preparing low-aromatic transformer oil through medium-pressure hydrogenation of naphthenic base distillate oil

A technology for naphthenic distillate oil and transformer oil is applied in the field of medium-pressure hydrogenation of naphthenic distillate oil to produce low-aromatic transformer oil, and can solve the problem of heavy distillation range, poor coal tar quality, and no effective grading of catalysts in the hydrogenation stage. and other problems, to achieve the effect of low hydrogen consumption, safe operation, and good oxidation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

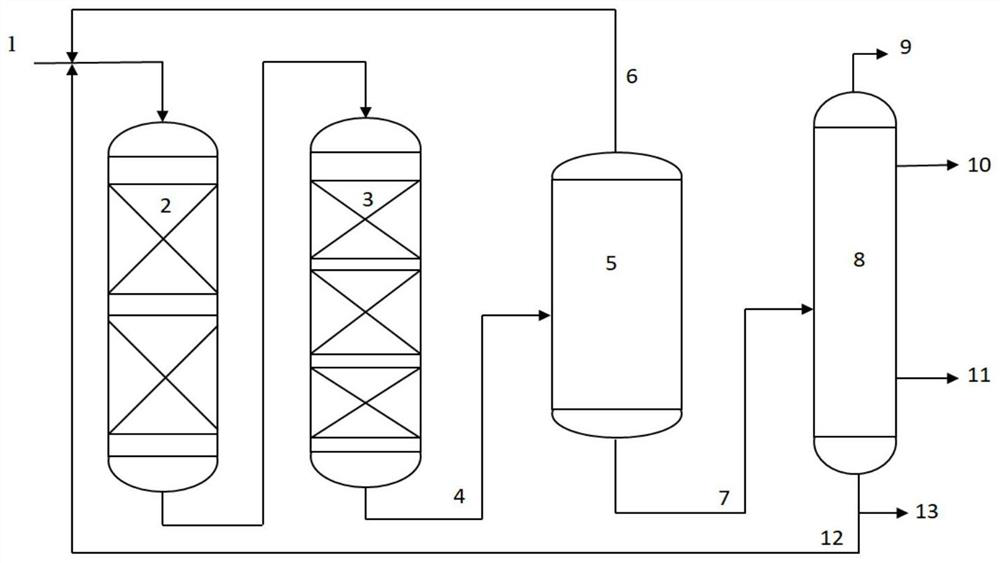

Method used

Image

Examples

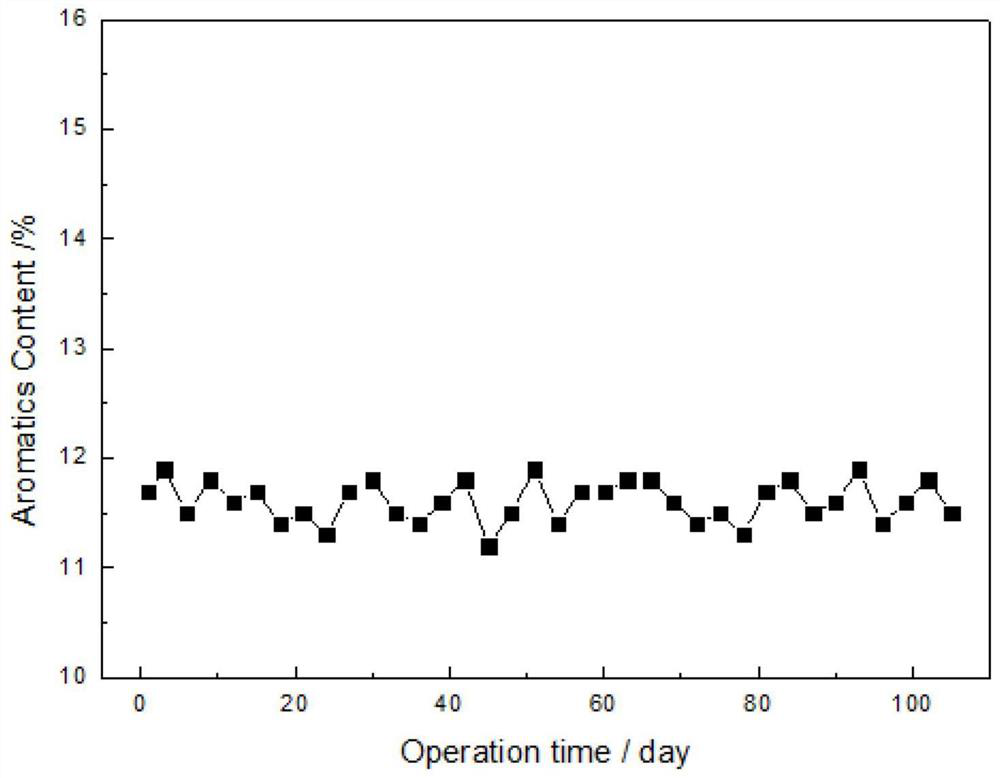

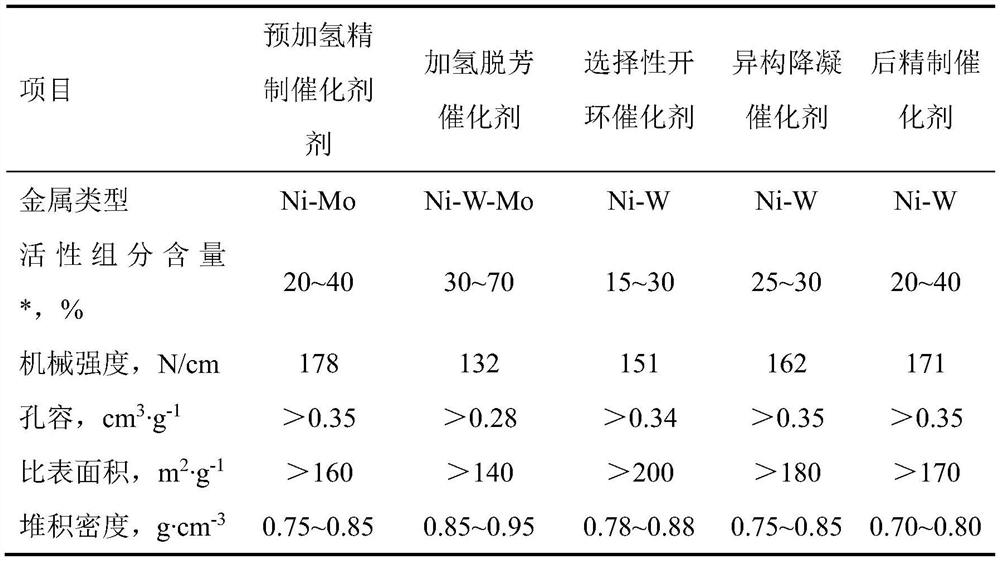

Embodiment 1

[0031] The normal second-line distillate produced by processing offshore naphthenic crude oil from a refinery's atmospheric and vacuum unit is used as the raw material. The properties of the raw material are shown in Table 2. After the raw material is mixed with hydrogen, it passes through the first hydrogenation reactor and the second hydrogenation reactor in sequence, and the volume space velocity of the feed is 1.0h -1 , the volume ratio of hydrogen to oil is 800:1, the hydrogen partial pressure of the system is 9.5MPa, wherein, the loading volume ratio of the pre-refining catalyst and the hydrodearomatization catalyst in the first reactor is 2:1, and the average reaction temperatures of the two catalysts are respectively 340°C and 350°C, the loading volume ratio of the selective ring-opening catalyst, isomerization decondensation catalyst and post-refining catalyst in the second reactor is 3:6:1, and the average reaction temperatures of the three catalysts are 350°C, 350°C,...

Embodiment 2

[0033] The first-line distillate oil obtained from the atmospheric and vacuum unit of a refinery processing offshore naphthenic crude oil is used as the raw material. The properties of the raw material are shown in Table 2. After the raw material is mixed with hydrogen, it passes through the first hydrogenation reactor and the second hydrogenation reactor in sequence, and the volume space velocity of the feed is 1.0h -1 , the volume ratio of hydrogen to oil is 800:1, the hydrogen partial pressure of the system is 9.5MPa, wherein, the loading volume ratio of the pre-refining catalyst and the hydrodearomatization catalyst in the first reactor is 1:1, and the average reaction temperatures of the two catalysts are respectively 350°C and 360°C, the loading volume ratio of selective ring-opening catalyst, isomerization decondensation catalyst and post-refining catalyst in the second reactor is 4:5:1, and the average reaction temperatures of the three catalysts are 350°C, 360°C and 3...

Embodiment 3

[0035] The raw material is the distillate of heavy diesel oil from coal liquefaction processed by the direct coal liquefaction unit of a certain enterprise. The properties of the raw material are shown in Table 2. After the raw material is mixed with hydrogen, it passes through the first hydrogenation reactor and the second hydrogenation reactor in sequence, and the volume space velocity of the feed is 0.5h -1 , the volume ratio of hydrogen to oil is 1200:1, the hydrogen partial pressure of the system is 9.5MPa, wherein, the loading volume ratio of the pre-refining catalyst and the hydrodearomatization catalyst in the first reactor is 1:2, and the average reaction temperatures of the two catalysts are respectively 360°C and 370°C, the loading volume ratio of the selective ring-opening catalyst, isomerization decondensation catalyst and post-refining catalyst in the second reactor is 5:4:1, and the average reaction temperatures of the three catalysts are 360°C, 365°C and 375°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com