Small frequency scanning horn antenna based on microstrip array feed

A technology of microstrip array and horn antenna, applied in the fields of microwave antenna, radar and wireless communication, can solve the problems of large antenna size and reduce the size of the horn antenna, and achieve the effect of reducing the size, shortening the length of the horn, and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

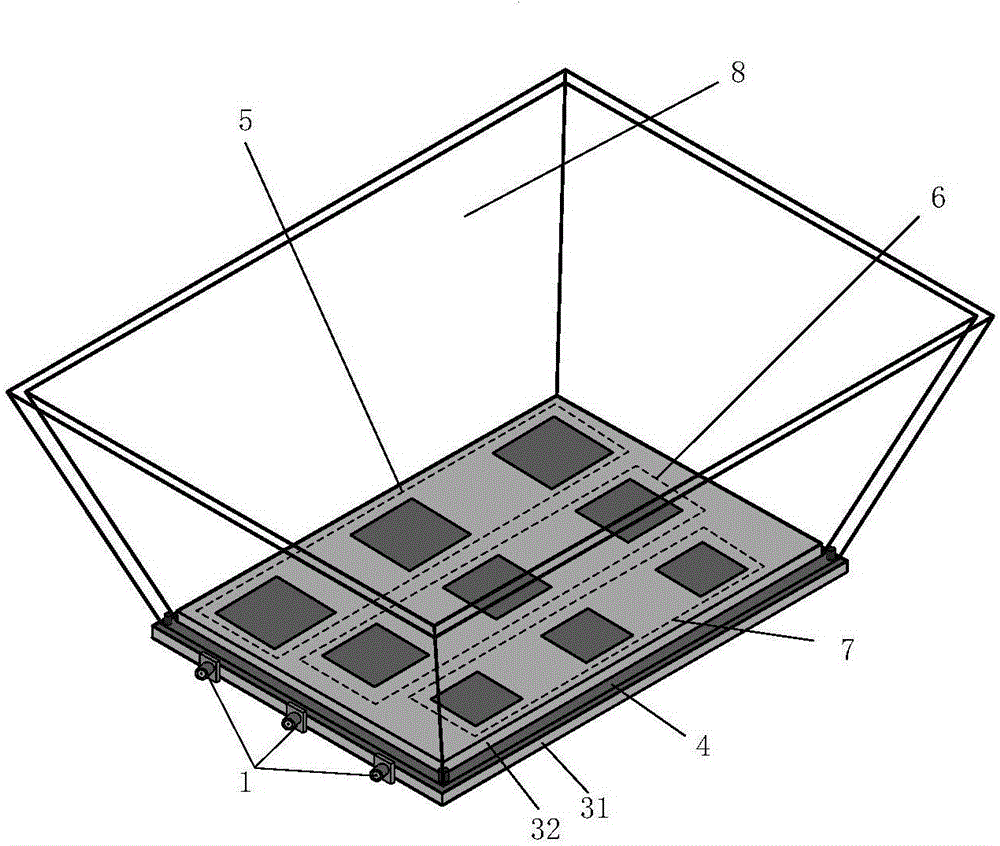

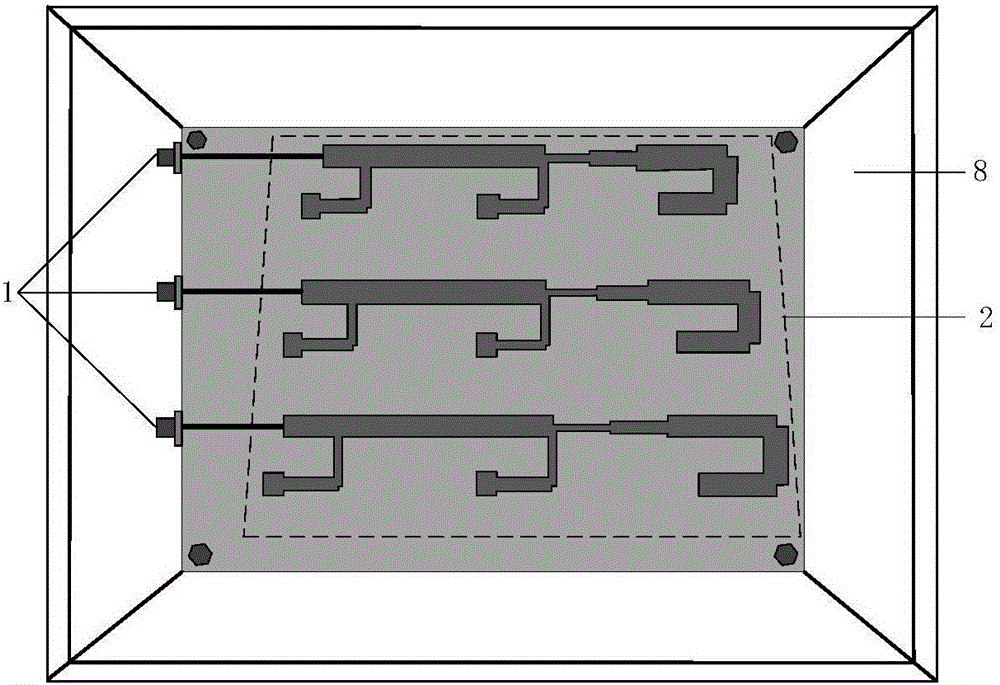

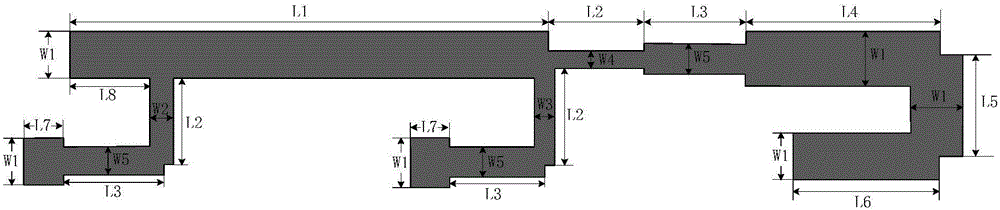

[0021] In the prior art, the design of the horn antenna is more complicated by the design of the loaded dielectric lens structure, which cannot effectively reduce the volume of the horn antenna structurally. Therefore, the present invention proposes a microstrip array-based feeding Miniaturized frequency-swept horn antenna. see figure 1 , a dielectric substrate is installed at the bottom of the rectangular horn 8, the dielectric substrate is divided into a lower dielectric substrate 31 and an upper dielectric substrate 32, the middle of the lower dielectric substrate 31 and the upper dielectric substrate 32 is a radiation floor 4, wherein the lower dielectric substrate 31 and the radiation floor 4 have the same length and width, the lower surface of the lower dielectric substrate 31 is etched with the feed network 2, and one side of the lower dielectric substrate 31 is equipped with a coaxial feed connector 1 for connecting to an external power supply. The upper dielectric su...

Embodiment 2

[0025] The overall composition and specific structure of the miniaturized frequency-swept horn antenna based on microstrip array feeding are the same as in Embodiment 1, see figure 1 , the patch array of the present invention is n groups of sub-arrays of different sizes arranged in parallel, the square radiation patch in each component array is placed parallel to the H plane direction of the rectangular horn 8, and the n component arrays are along the E plane of the rectangular horn 8 The directions are arranged from large to small or from small to large, and n is an odd number greater than 1, which can be 3, 5, 7..., and the specific value depends on the size of the bottom port of the horn antenna in the project. In this example, n is 5, that is to say, there are 5 component arrays to form the overall patch array. In this example, the sub-arrays are arranged in parallel along the E-plane direction of the rectangular horn 8 from small to large, and work in 12GHz, 11GHz, 10GHz,...

Embodiment 3

[0027] The overall composition and specific structure of the miniaturized frequency-swept horn antenna based on microstrip array feeding are the same as those in Embodiment 1-2. In the present invention, n-component arrays of different sizes correspond to square radiation patch arrays at different operating frequencies, see figure 1, the sub-arrays work at different frequencies in a one-to-one correspondence, and each sub-array works at a fixed frequency. The effect of the horn wall is used to make the pattern of the left and right sub-arrays deviate from the main direction. The degree of deviation of the pattern is the same as that of the sub-array The distance to the horn wall on that side is inversely proportional, with the pattern of the centrally located sub-array facing the main direction. In this example, the main direction is the direction facing the horn radiation port, the sub-array located on the left side relative to the center position, the pattern is biased to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com