Nozzle of bladeless fan

A bladeless fan and nozzle technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve the problems of large use area, difficult mixing, and affecting air volume, so as to increase the air supply distance, double the airflow velocity, The effect of reducing the number of motor revolutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

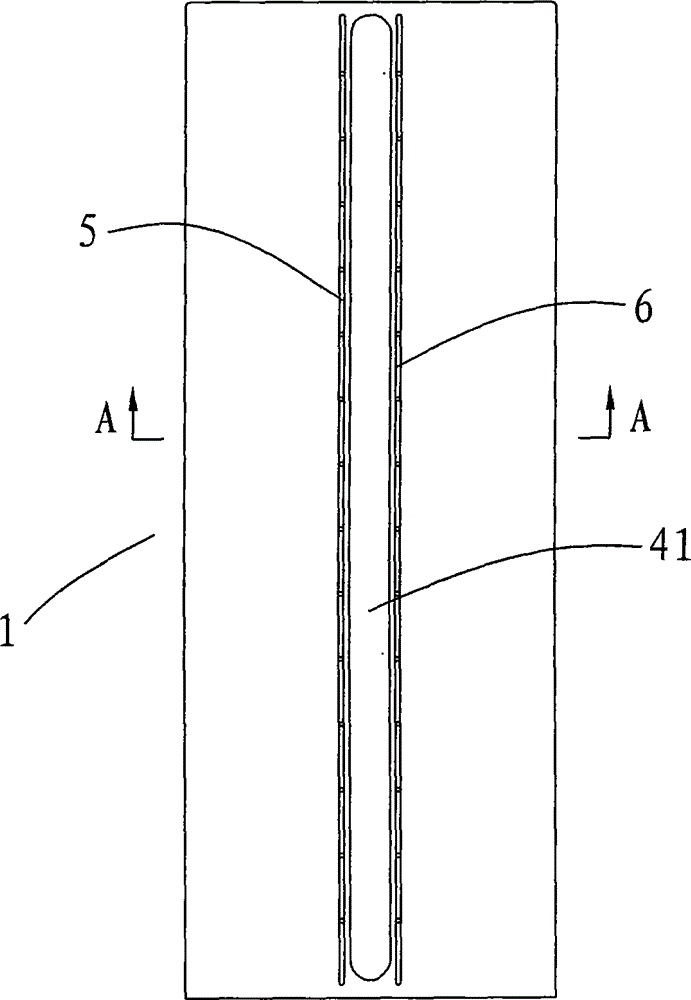

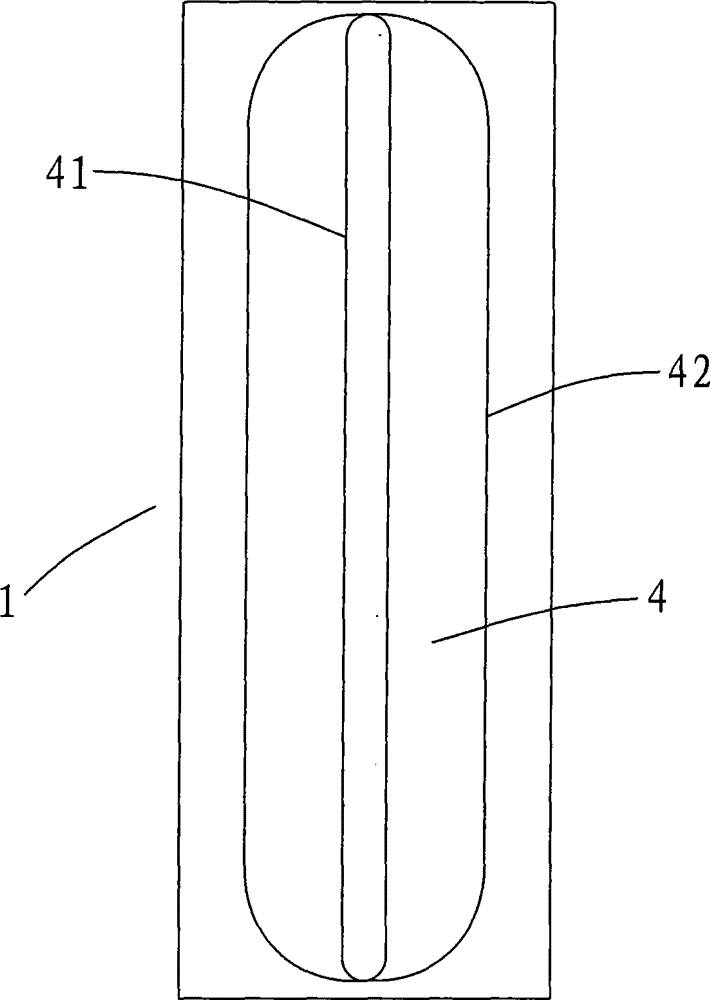

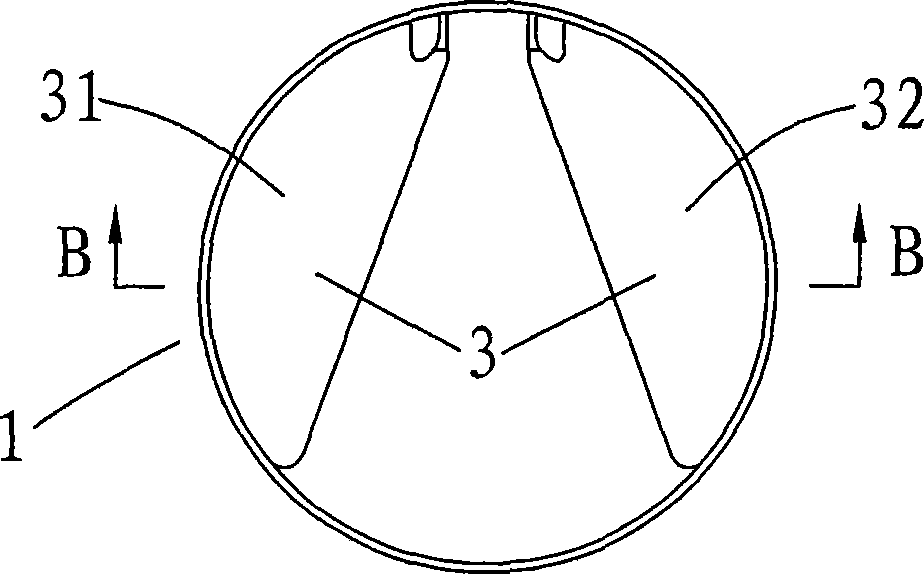

[0031] like Figure 1 to Figure 7 As shown, as a preferred embodiment of the present invention, the bladeless fan nozzle is used in conjunction with the fan assembly that generates the basic airflow, which includes a nozzle body 1, and the nozzle body 1 is provided with a receiving port 2 and an internal passage for receiving the basic airflow 3. The nozzle body 1 is also provided with an air guide port 4 for guiding external air to pass through. The front end of the air guide port 4 is provided with a strip-shaped narrow opening 41, and the rear end of the air guide port 4 is provided with a wide opening 42 whose width is greater than the strip-shaped narrow opening 41. The wide opening 42 can be a waist-shaped opening or a rectangular opening. The definition of the strip-shaped narrow opening 41 means: the opening is made up of two opposite long sides and two opposite short sides, the length of the two long sides is far greater than the width of the two short sides, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com