Double-ridged horn antenna based on specially-shaped ridge loading

A ridged horn, special-shaped technology, applied in the direction of antenna, waveguide horn, antenna grounding switch structure connection, etc., can solve the problems of stiff transition and gain sag, and achieve the effect of smooth transition of impedance transformation and good impedance matching characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

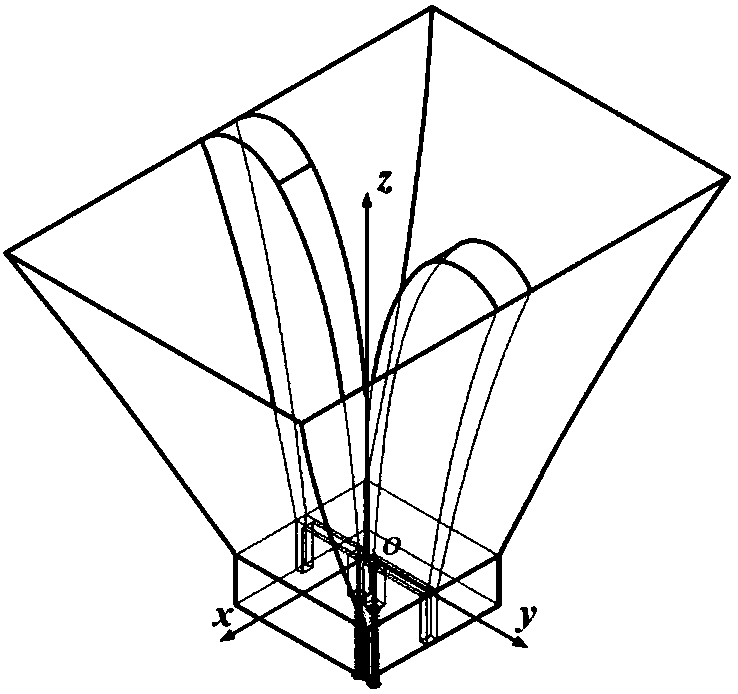

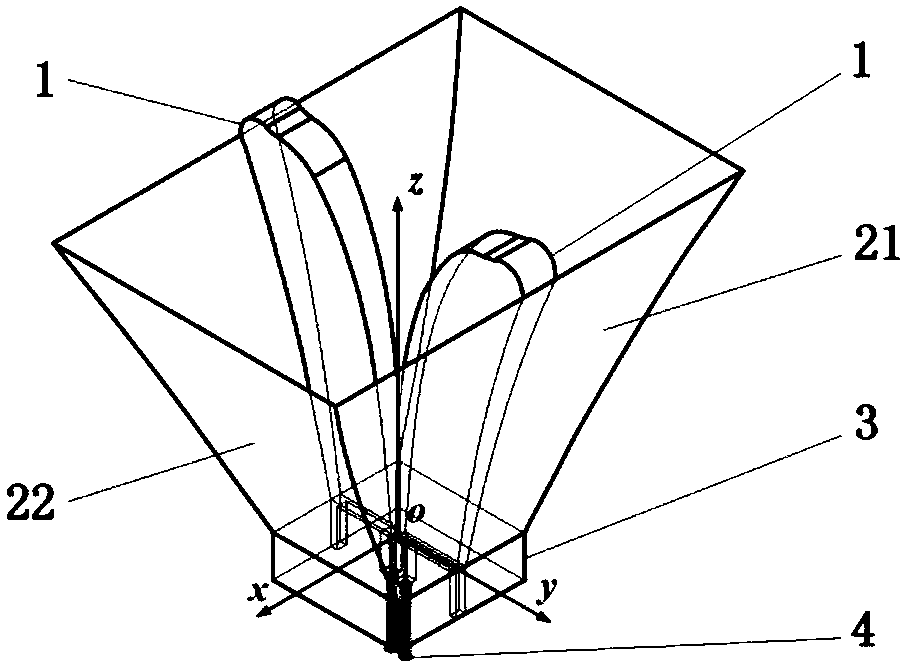

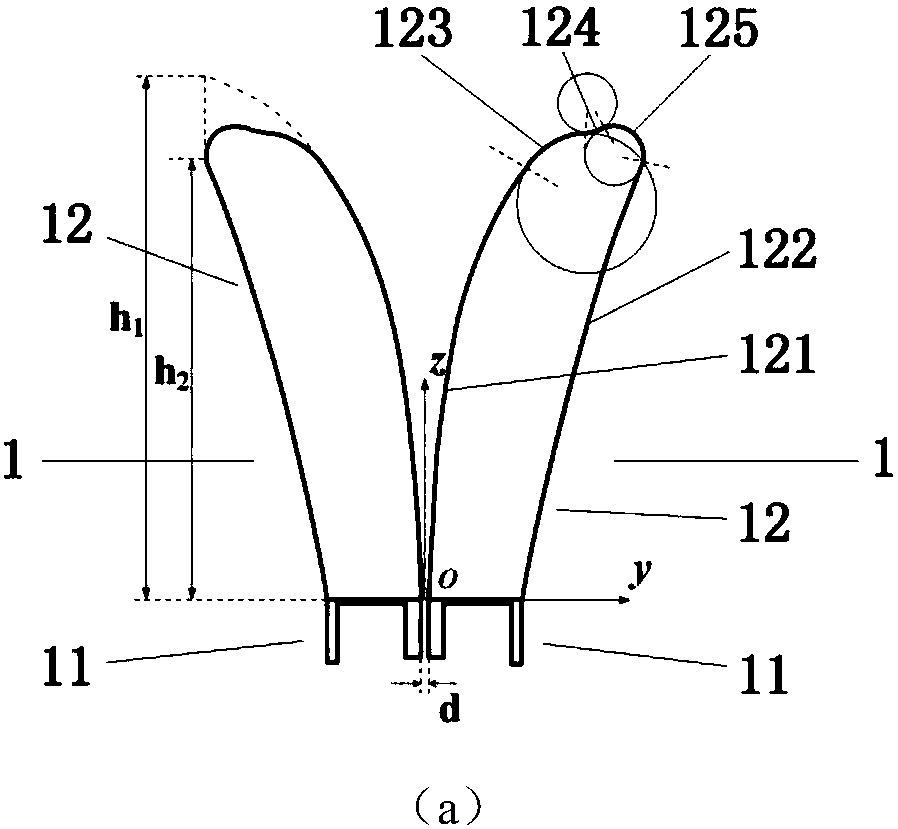

[0040] refer to figure 2 , a double-ridge horn antenna based on special-shaped ridge loading, including two oppositely arranged special-shaped ridge plates 1, a horn housing 2, a back cavity 3 and a feeding coaxial line 4, and the special-shaped ridge plate 1 includes a back cavity matching section 11 and The special-shaped transition section 12; the ridge line of the special-shaped transition section 12 is smoothly connected by two sections of exponential curves and three sections of arcs; A rectangular horn structure formed by splicing each other, wherein the curvature of the curved metal wall 21 is the same as that of the second exponential curve 122; 40mm×13mm cuboid structure; the open end of the back chamber 3 is connected to the bottom end of the speaker housing 2, and the two special-shaped ridge plates 1 are respectively loaded on different curved metal walls 21, and the feed coaxial line 4 The shielding layer is connected to the back cavity 3 , and the inner core p...

Embodiment 2

[0046] The structure of this embodiment is the same as that of Embodiment 1, only the distance d between the two ridges of the two oppositely arranged special-shaped ridges 1 and the thickness t of the special-shaped gradual change section 12 1 and t 2 , the first exponential curve 121 gradient curvature control variable h 1 , second exponential curve 122 gradient curvature control variable h 2 and the parameters of the three arcs have been adjusted:

[0047] The double-ridge spacing d=1mm of the special-shaped ridge plate 1; the thickness of the special-shaped gradual change section 12 is from bottom to top by t 1 = 1mm uniform gradient to t 2 =5mm; its first exponential curve expression is h 1 =80mm, the expression of the second exponential curve is h 2 =75mm, (y of the center control point coordinates corresponding to the first arc segment 123 1 ,z 1 ) is (27.1mm, 65mm), and its radius is r 1 =11mm, (y of the center control point coordinates corresponding to the...

Embodiment 3

[0049] The structure of this embodiment is the same as that of Embodiment 1, only the distance d between the two ridges of the two oppositely arranged special-shaped ridges 1 and the thickness t of the special-shaped gradual change section 12 1 and t 2 , the first exponential curve 121 gradient curvature control variable h 1 , second exponential curve 122 gradient curvature control variable h 2 and the parameters of the three arcs have been adjusted:

[0050] The double-ridge spacing d=3mm of the special-shaped ridge plate 1; the thickness of the special-shaped gradual change section 12 is from bottom to top by t 1 = 4mm uniform gradient to t 2 =50mm; its first exponential curve expression is h 1 =120mm, the expression of the second exponential curve is h 2 =95mm; (y of the center control point coordinates corresponding to the first arc segment 123 1 ,z 1 ) is (42.3mm, 96mm), and its radius is r 1 =16mm, (y of the center control point coordinates corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com