Horn structure with internal bracket

A technology of inner brackets and speakers, which is applied in the direction of electrical components, sensors, etc., can solve the problems of not being able to take into account the dual enjoyment of vision and hearing, lowering the minimum resonance frequency, and large combined volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

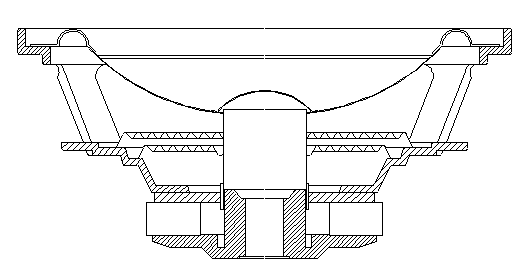

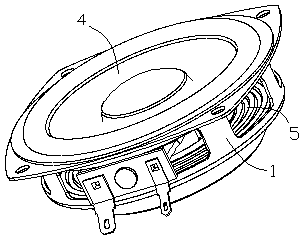

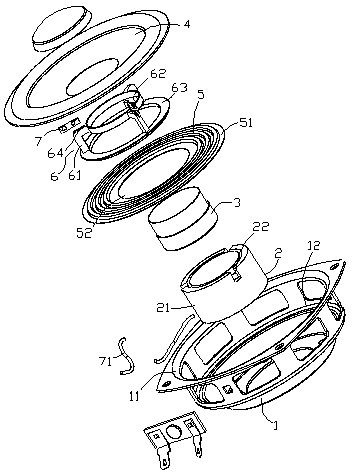

[0025] In order to make a further understanding of the structural composition of the present invention and its operational functions, now cooperate with the drawings to explain as follows; as Figure 2~4 Shown, a kind of inner bracket loudspeaker structure provided by the present invention mainly comprises:

[0026] A housing 1 with an enlarged opening 11 at the front and a magnetic return 2 at the rear;

[0027] a voice coil 3, placed in the middle of the magnetic loop 2, and;

[0028] A vibrating membrane 4, which is placed on the enlarged opening 11 of the casing, and its inner diameter is glued to the voice coil 3;

[0029] Its improved features are:

[0030] A spring wave plate 5, the outer edge 51 is set on the inner step 12 of the shell 1, the inner hole 52 is sleeved on the side wall 21 of the magnetic loop 2, and a plurality of slots 22 are axially spaced above the magnetic loop 2, as well as;

[0031] An inner bracket 6, the upper part is arranged on the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com