Vector microphone with horn structure

A microphone and vector technology, which is used in the measurement of propagation velocity, ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems such as the difficulty of miniaturizing the size of the measuring device and the limited measurement range, so as to improve the sensitivity and improve the signal-to-noise ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings and embodiments

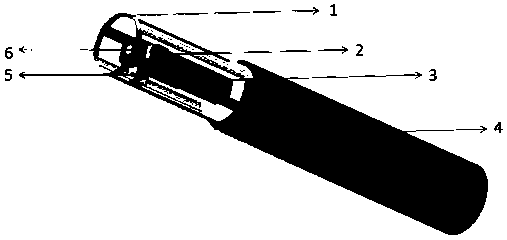

[0022] Such as figure 1 Shown: the present invention includes a support rod 3, in the upper end of the support rod is embedded MSM262S4737Z0A sound pressure microphone sensor 6 produced by MEMSensing company, on the adjacent two sides of the support rod are attached with x-directional bell mouth sensitive elements 2 and y respectively To the bell-mouth sensitive component 5, on the outside of the support rod is a protective cover 1 with protective effect, and under the protective cover is a circuit board compartment 4 where circuit components are placed.

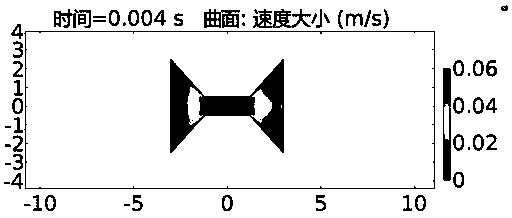

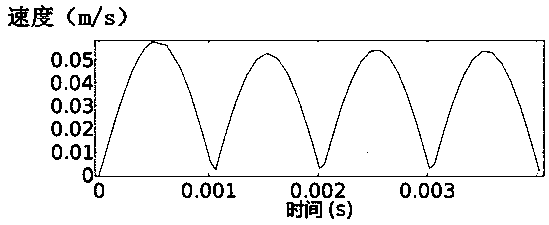

[0023] When measuring, when sound waves act on the MEMS sound pressure microphone sensor, the sound pressure information can be directly measured through the circuit connection. When sound waves pass through the bell mouth and act on the sensitive components, the bell mouth sensitization structure will increase the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com