0.5THz corrugated horn antenna and preparation method using MEMS technology

A technology of corrugated horns and antennas, applied in waveguide horns, optical waveguide coupling, TV system components, etc., can solve the problems of difficult frequency coverage and high cost, and achieve the effect of easy array formation, low cost, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

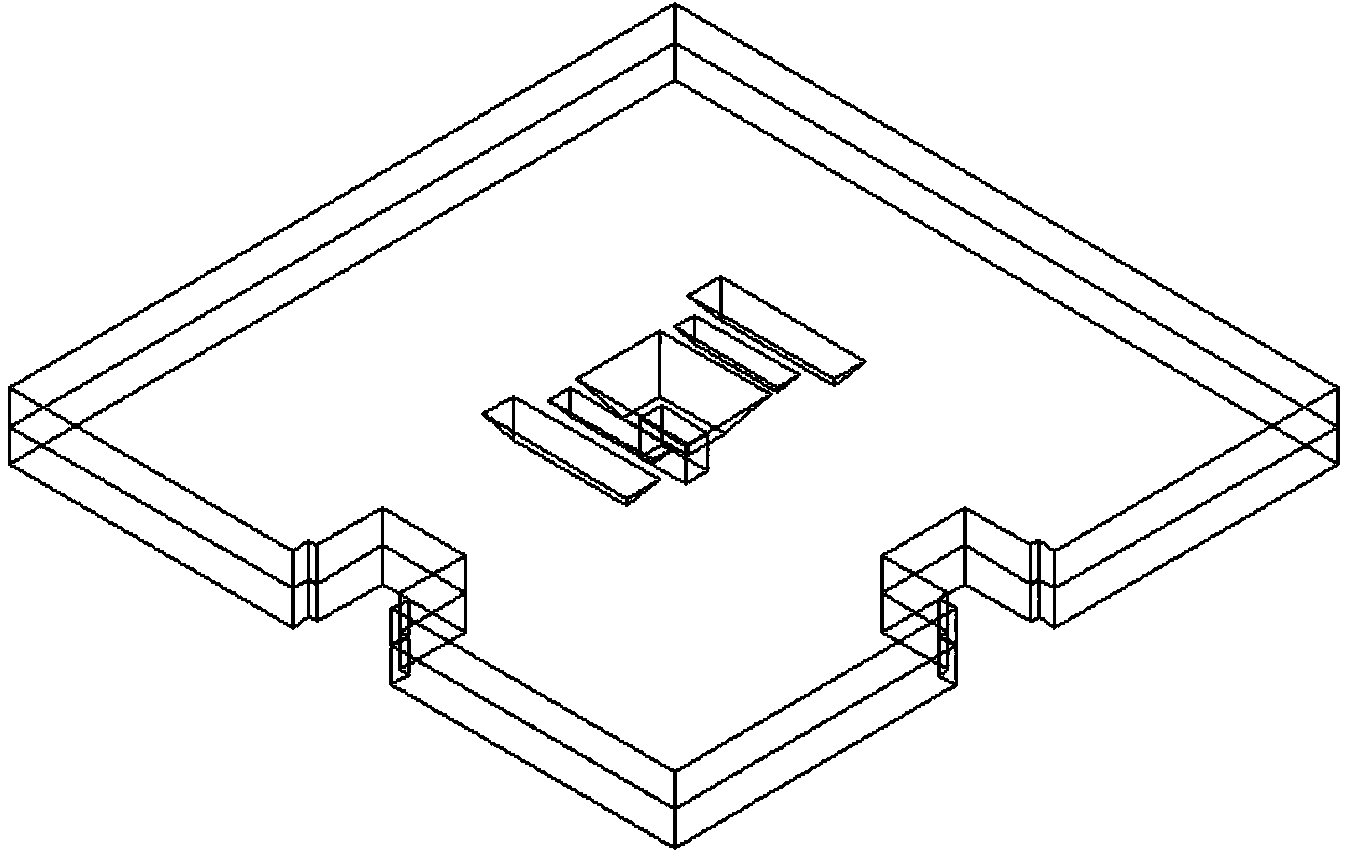

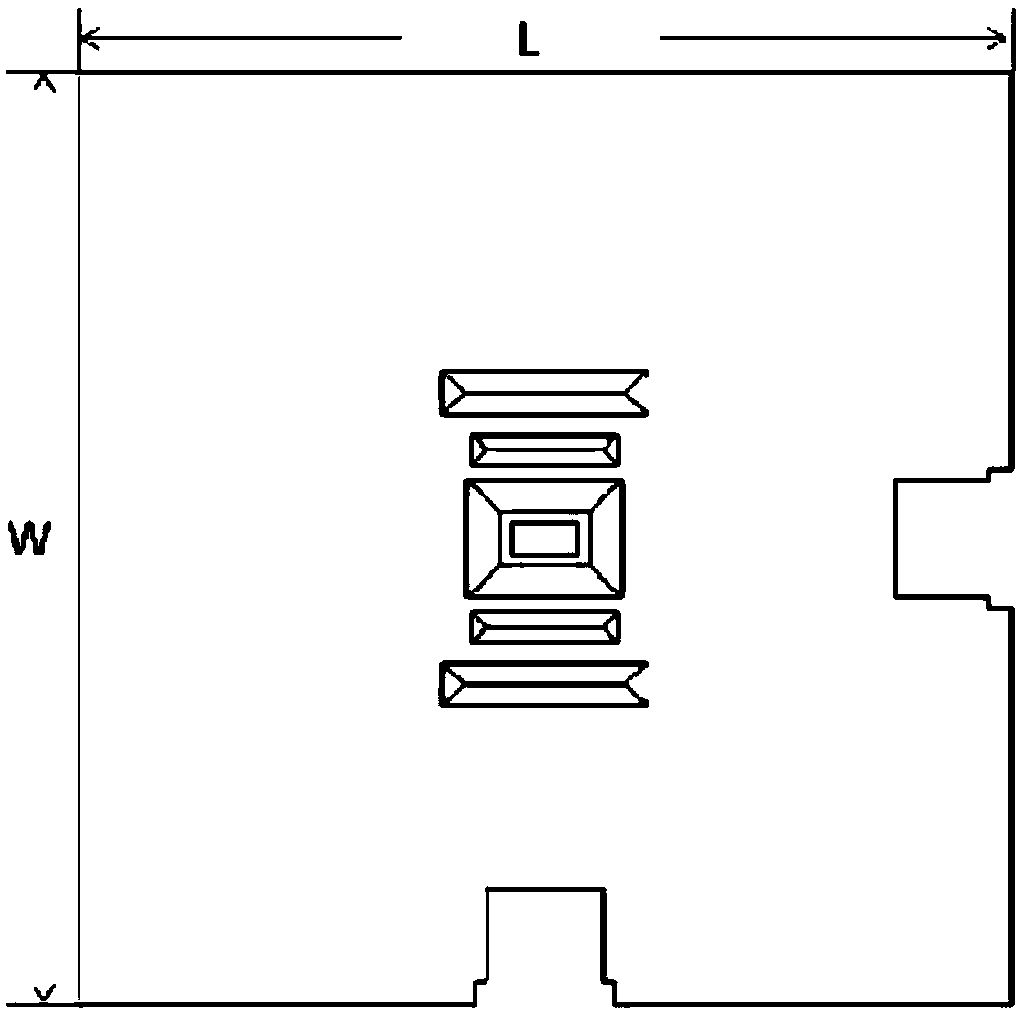

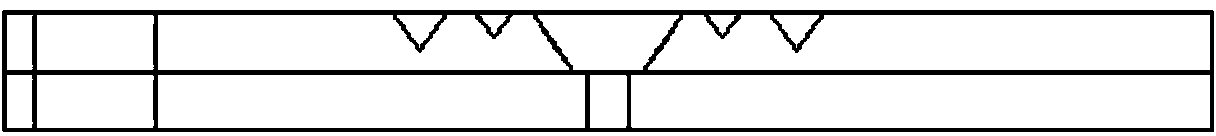

[0031] like figure 1 , figure 2 , image 3 As shown, a 0.5THz corrugated horn antenna, the antenna is a cuboid (8mm×8mm×0.8mm), and there is a positioning groove on the two adjacent sides of the cuboid, which is mainly used for pre-processing under the integrated process. There is a fixed card slot for the antenna fixture; there is a horn structure at the center of the upper surface of the cuboid. The size of the horn mouth is 1.34mm×1.02mm, shrinking at an angle of 54.7° with the silicon wafer plane, and the length of the horn is 0.4 mm; below the horn structure is a waveguide, the waveguide model WR2.2, the cross-sectional size is 0.56mm×0.28mm), and the length is 0.4mm; the horn structure and the waveguide are connected by steps, and there are two on both sides of the horn structure. A V-shaped corrugated groove, the notch dimensions are 1.25mm×0.25mm and 1.75mm×0.375mm respectively, shrinking at an angle of 54.7° with the silicon wafer plane.

[0032] A method for prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com