Micro-nano bubble enhanced plasma polishing method

A technology of micro-nano bubbles and plasma, which is applied in the field of plasma polishing, can solve problems such as hard and brittle materials that are difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

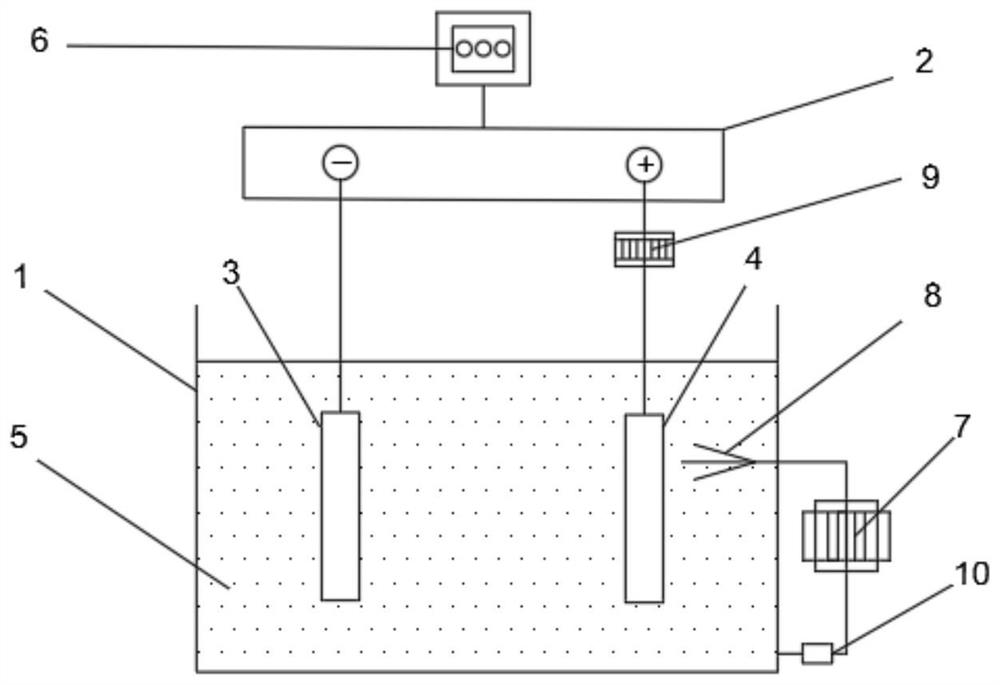

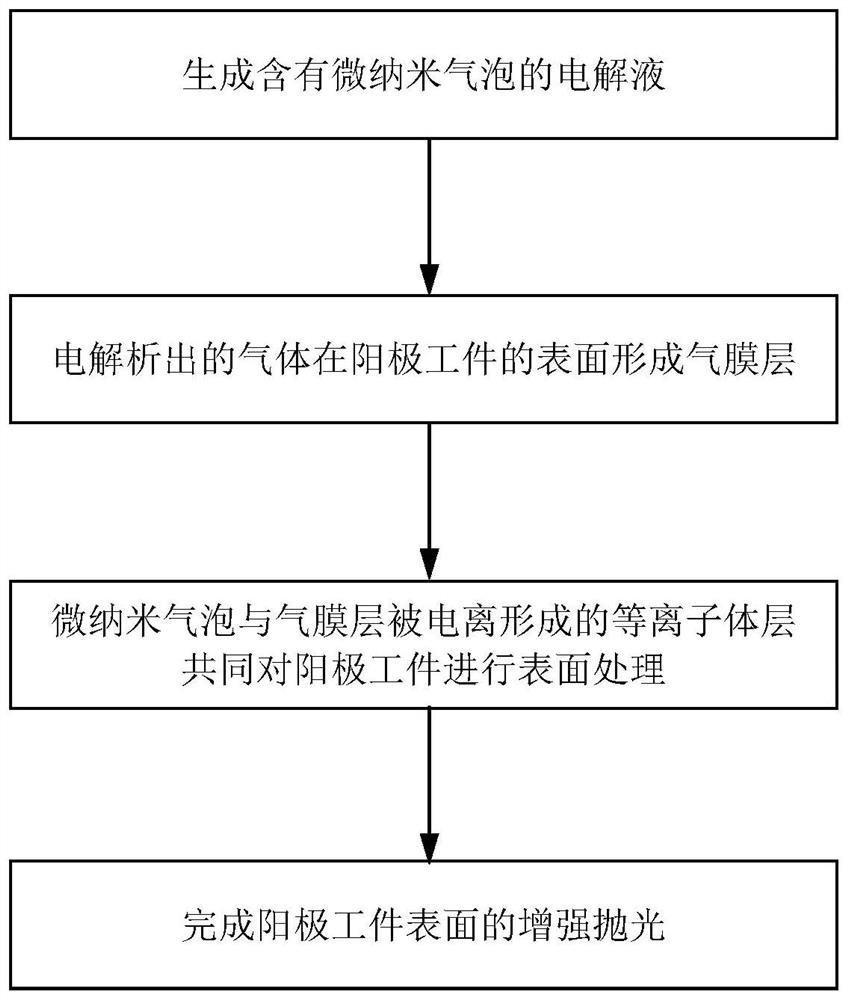

Method used

Image

Examples

Embodiment 1

[0071] Implementation conditions: The processed workpiece is a SUS316L stainless steel cylinder with a length of 50mm and a diameter of 50mm with an original roughness of 12μm.

[0072] Step 1: Configure an appropriate amount of electrolyte 5 in the working tank 1, start the control system 6, set the electrolyte preheating temperature to 55°C, and start processing after confirming that the preheating temperature has reached. The electrolytic solution is a 2wt% water-soluble solution with a pH of 5-7.

[0073]Step 2: Connect the cathode tool 3 and the anode workpiece 4 to the cathode and anode of the power supply system 2 respectively to ensure that the anode workpiece 4 is in close contact with the power supply system 2 and the workpiece movement mechanism 9 and has good conductivity. And the anode workpiece 4 is fixed in a proper position in the working tank 1, and rotates around the axis of the workpiece at a rotation speed of 50 rpm.

[0074] Step 3: Start the micro-nano b...

Embodiment 2

[0080] Implementation conditions: The workpiece to be processed is an In718 plate with a length of 200mm, a width of 20mm, a thickness of 2mm, and an original roughness of 2μm.

[0081] Step 1: Configure an appropriate amount of electrolyte 5 in the working tank 1, start the control system 6, set the electrolyte preheating temperature to 70°C, and start processing after confirming that the preheating temperature has reached. The electrolytic solution is a 4wt% water-soluble solution with a pH of 6-8.

[0082] Step 2: Connect the cathode tool 3 and the anode workpiece 4 to the cathode and anode of the power supply system 2 respectively to ensure that the anode workpiece 4 is in close contact with the power supply system 2 and the workpiece movement mechanism 9 and has good conductivity. And the anode workpiece 4 is vertically fixed in an appropriate position in the working tank 1, and the rotation speed of the workpiece is set at 5 rpm.

[0083] Step 3: Start the micro-nano bu...

Embodiment 3

[0089] Implementation conditions: The processed workpiece is a TC4 cylinder with a length of 30mm and a diameter of 60mm. There is a circular groove with a depth of 20mm and a width of 10mm in the center of the cylinder length. The original roughness of the entire workpiece surface is 3μm.

[0090] Step 1: Configure an appropriate amount of electrolyte 5 in the working tank 1, start the control system 6, set the electrolyte preheating temperature to 55°C, and start processing after confirming that the preheating temperature has reached. The electrolytic solution is a 5wt% water-soluble solution with a pH of 6-7.

[0091] Step 2: Connect the cathode tool 3 and the anode workpiece 4 to the cathode and anode of the power supply system 2 respectively to ensure that the anode workpiece 4 is in close contact with the power supply system 2 and the workpiece movement mechanism 9 and has good conductivity. And the anode workpiece 4 is vertically fixed in a proper position in the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com