Method for preparing enhanced GaN field effect device

A gallium nitride field and enhanced technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as lattice damage, damage barrier layer surface current, and difficult precise control, so as to improve device reliability. performance, improve current collapse, and reduce gate leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

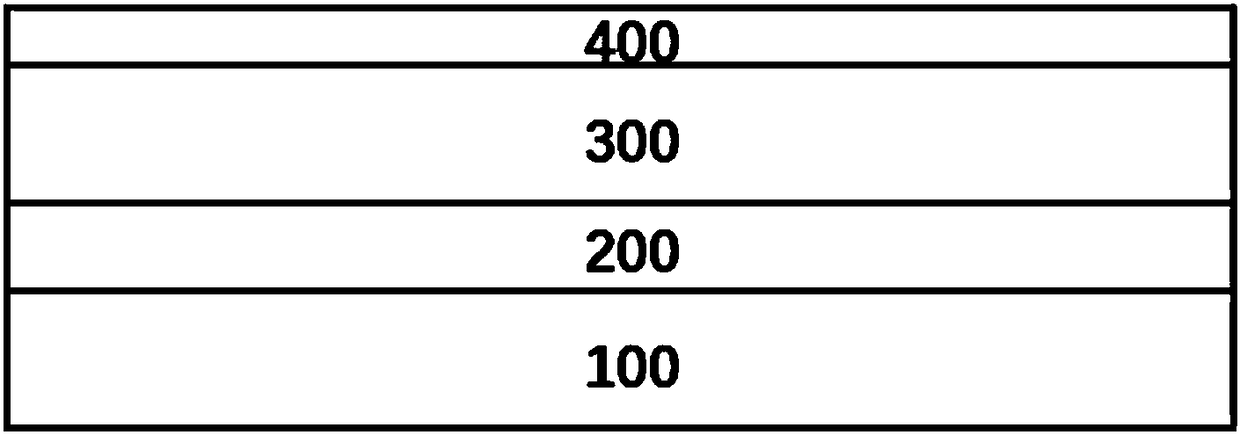

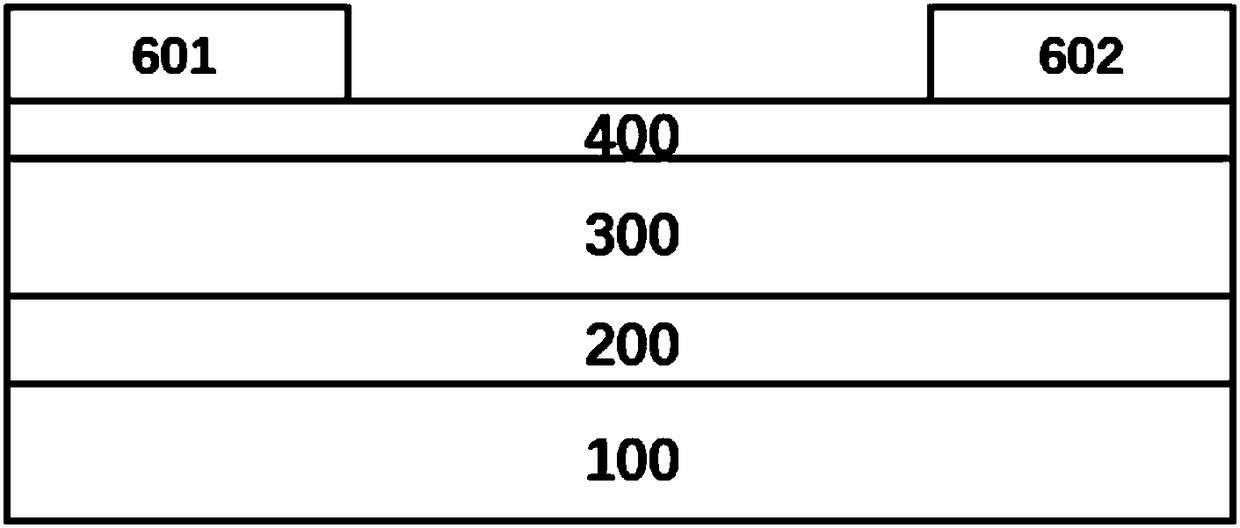

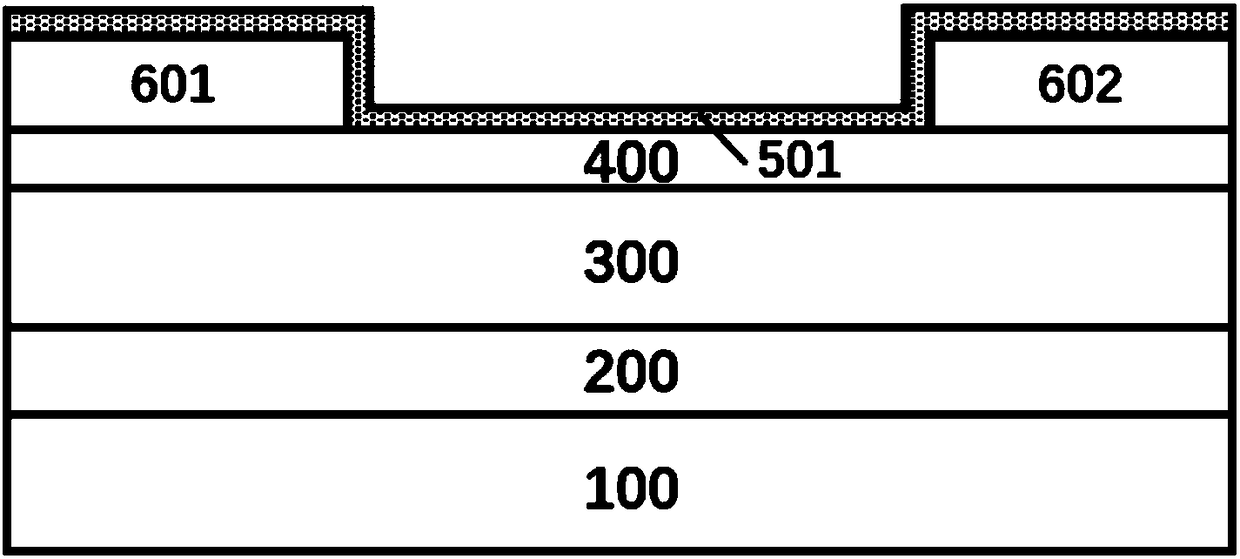

[0038] The device structure finally prepared by the method for manufacturing an enhancement mode gallium nitride field effect device according to an embodiment of the present invention. Such as Figure 7 As shown, the enhanced gallium nitride field effect device is mainly composed of the following parts: single crystal substrate 100, buffer layer 200, channel layer 300, barrier layer 400, two-dimensional material gate 501, source and drain metal electrodes 601 / 602 , a W gate metal electrode 603 , and a dielectric passivation layer 701 .

[0039] Figure 1 to Figure 7 It is a schematic diagram of the device structure according to various implementation steps of the manufacturing method of the enhancement mode GaN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com