Preparation method of grid enhanced gallium nitride field effect device with P type 2D material

A two-dimensional material and gallium nitride field technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as lattice damage, difficulty in precise control, and surface current of damaged barrier layers, so as to improve device performance. Reliability, reducing gate leakage, improving the effect of current collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0033] Figure 1-Figure 7 It is a flowchart of a method for manufacturing a P-type two-dimensional material gate-enhanced gallium nitride field effect device according to an embodiment of the present invention, which specifically includes the following steps:

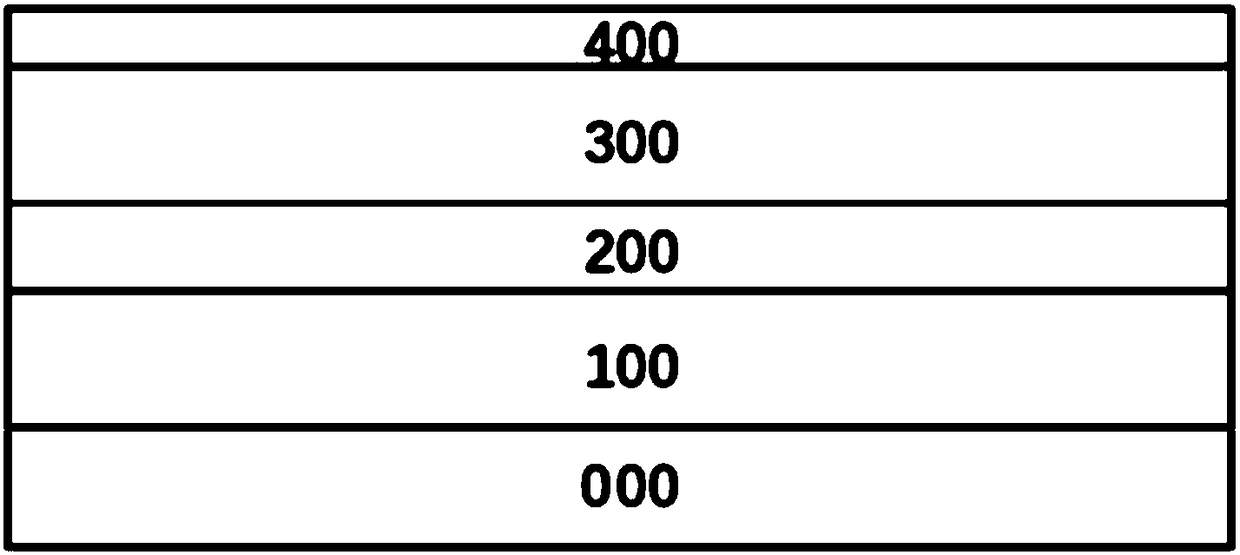

[0034] Step 1) epitaxy the AlGaN buffer layer 100, the GaN channel layer 200, the AlGaN barrier layer 300, and the GaN interface control layer 400 sequentially on the single crystal substrate 000, such as figure 1 shown.

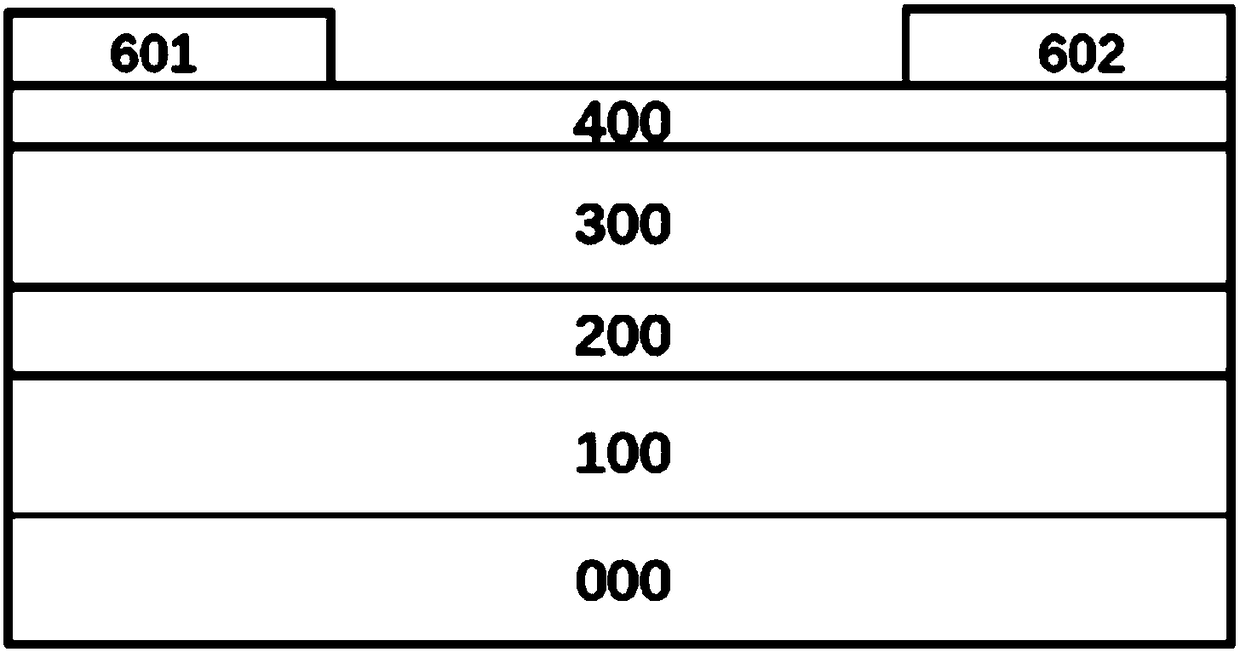

[0035] Step 2) Deposit Ti / TiN / Al source and drain metals 601, 602 to form ohmic contacts through superalloys, such as figure 2 shown.

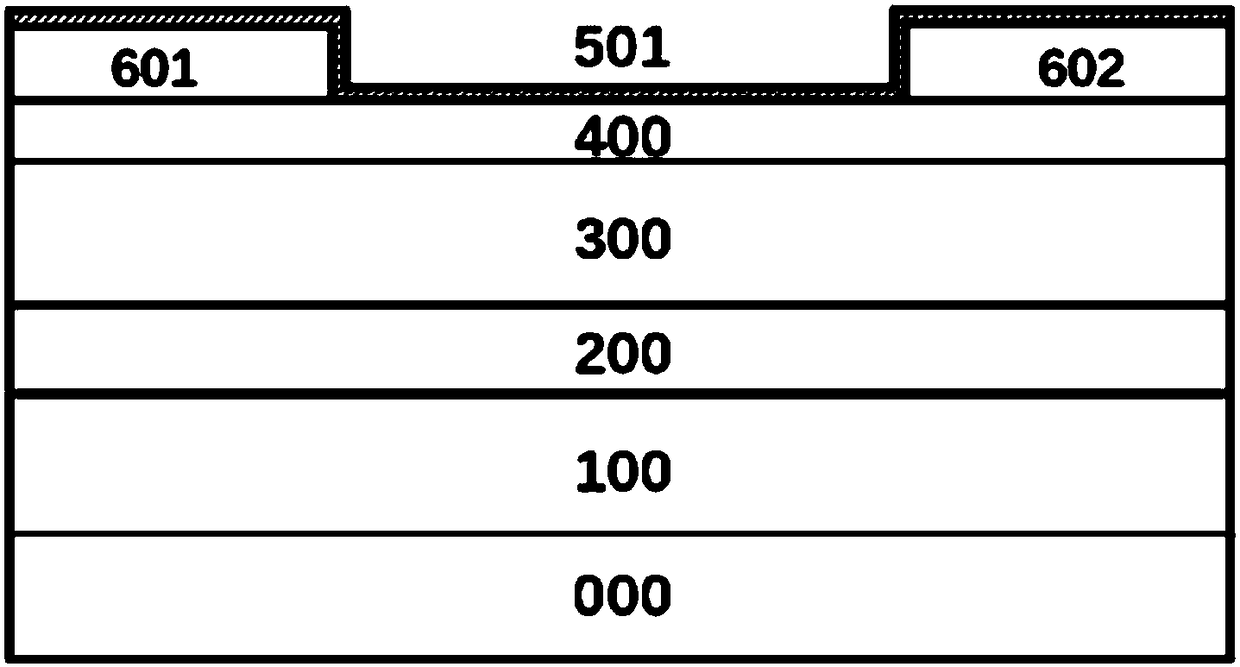

[0036] Step 3) epitaxy the P-type WSe by CVD above the GaN interface control layer 2 Layer 501, such as image 3 shown.

[0037] Step 4) Defining the gate metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com