Laser sleeving-nesting type composite processing method

A technology of compound processing and processing scheme, which is applied in the field of laser nested compound processing, can solve problems such as not applicable to the field of micro-nano manufacturing, complex process steps, clamping errors, etc., to improve processing quality, simplify processing flow, and reduce position effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

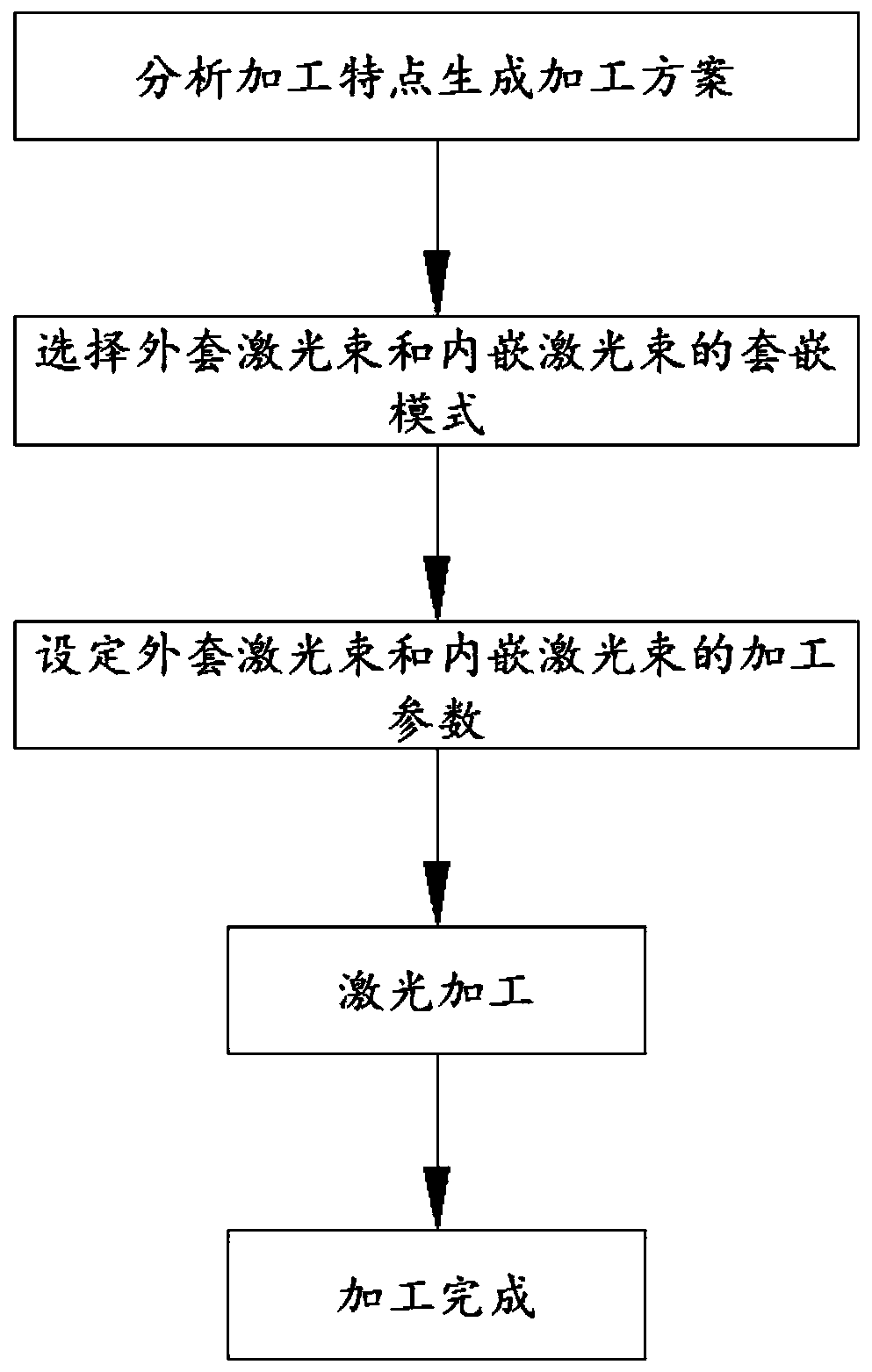

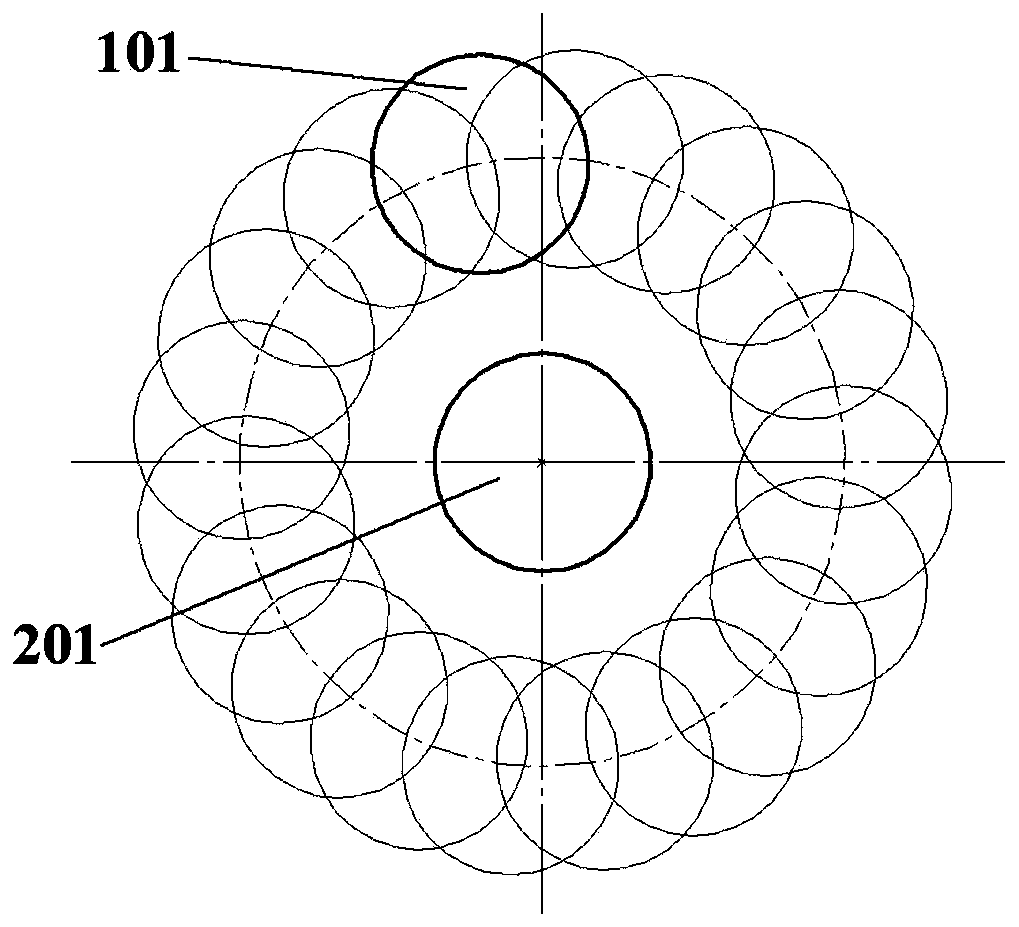

[0051] Such as figure 1 and 2 As shown, a laser nested compound processing method comprises the following steps:

[0052] (1) Analysis of the workpiece: the workpiece is copper metal, and the workpiece must be processed with high efficiency and high quality of small-diameter circular through-holes, and the copper has a low absorption rate for the laser with a wavelength of 10.6 μm;

[0053] (2) Processing mode setting: select the nesting mode of the outer laser beam and the embedded laser beam;

[0054] (3) Processing parameter setting: the processing parameters of the selected jacket laser beam 101 are the wavelength of 10.6 μm, the pulse width range of 100 ns, the output energy power adjustment range of 15 W, the repetition frequency range of 100 kHz, the defocus amount of 0 mm, and the processing method It is circular processing; the processing parameters of the embedded laser beam 201 are selected as wavelength 10.6μm, pulse width range is 20fs, output energy power adjus...

Embodiment 2

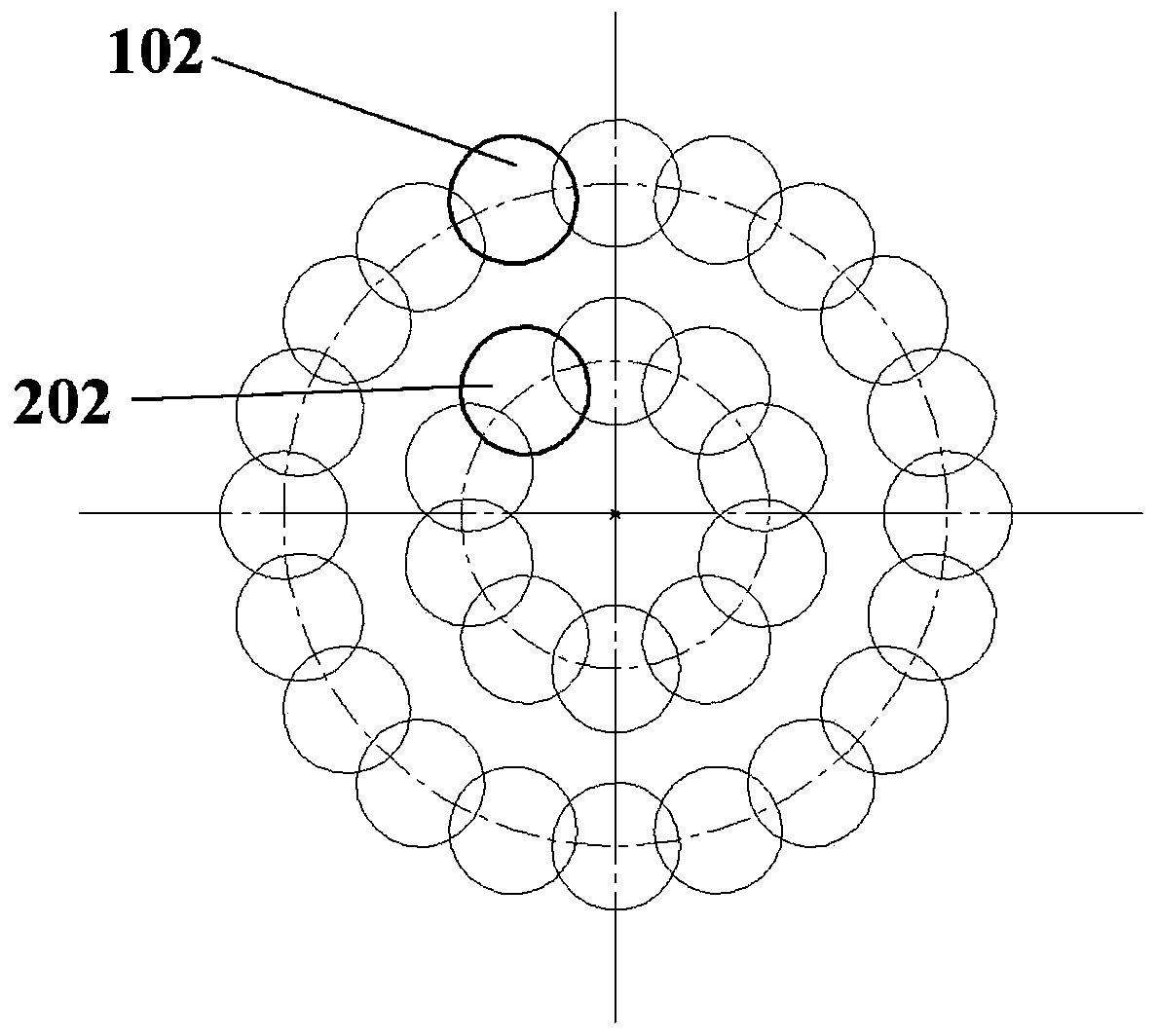

[0057] Such as figure 1 and 3 As shown, a laser nested compound processing method comprises the following steps:

[0058] (1) Workpiece analysis: The workpiece is made of aluminum alloy metal material, and the workpiece must realize efficient and high-quality processing of large-diameter circular blind holes;

[0059] (2) Processing mode setting: select the nesting mode of the outer laser beam and the embedded laser beam;

[0060] (3) Processing parameter setting: Therefore, the processing parameters of the selected jacket laser beam 102 are wavelength 1064nm, pulse width range is 80fs, output energy power adjustment range is 2W, repetition frequency range is 100kHz, defocusing amount is 0mm, processing method It is ring processing; the processing parameters of the embedded laser beam 202 are selected as wavelength 532nm, pulse width range is 40ns, output energy power adjustment range is 8W, repetition frequency range is 100kHz, defocus amount is 0mm, and the processing meth...

Embodiment 3

[0063] Such as figure 1 and 4 As shown, a laser nested compound processing method comprises the following steps:

[0064] (1) Workpiece analysis: The workpiece is made of ceramic material, because the workpiece needs to realize efficient processing of small diameter circular blind holes;

[0065] (2) Processing mode setting: select the nesting mode of the outer laser beam and the embedded laser beam;

[0066] (3) Processing parameter setting: Therefore, the processing parameters of the selected jacket laser beam 103 are wavelength 355nm, pulse width range is 80fs, output energy power adjustment range is 5W, repetition frequency range is 100kHz, defocusing amount is 0mm, processing method For percussion processing, and carry out airspace shaping to form an annular spot; the processing parameters of the selected embedded laser beam 203 are wavelength 1064nm, pulse width range 200ns, output energy power adjustment range 20W, repetition frequency range 100kHz, defocus amount is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com