Method for preparing mesoporous carbon having iron oxide nanoparticles

A technology of iron oxide nanometer and mesoporous carbon, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of reducing adhesion ability, catalytic ability, blocking pores of nanoparticles, and restricting effective use, so as to ensure economical Performance and convenience, and the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A specific example of the method for preparing mesoporous carbon containing iron oxide nanoparticles of the present invention includes the following steps: step 1), dispersing and saturating iron oxide nanoparticles on the surface of the mesoporous carbon; step 2), calcining the above-mentioned mesoporous carbon .

[0022] In the preparation method of mesoporous carbon containing iron oxide nanoparticles of the present invention, the iron oxide nanoparticles in the above step 1) contain Fe 2 o 3 and Fe 3 o 4 More than one of the groups formed.

[0023] In the method for preparing mesoporous carbon containing iron oxide nanoparticles of the present invention, the above step 1) can be performed by a dipping method. The above-mentioned impregnation method is a method for separately synthesizing and attaching nanoparticles, and refers to a method of synthesizing a carrier with nanoparticles attached by adhering dispersed nanoparticles to the surface of a carrier after s...

Embodiment 1

[0034] Example 1: Preparation of mesoporous carbon with iron oxide nanoparticles attached

[0035] Tetraethyl orthosilicate (TEOS, tetraethyl orthosilicate) was used as a silica template material, and mesoporous carbon was prepared by a hard-template method (kim et al., 2004).

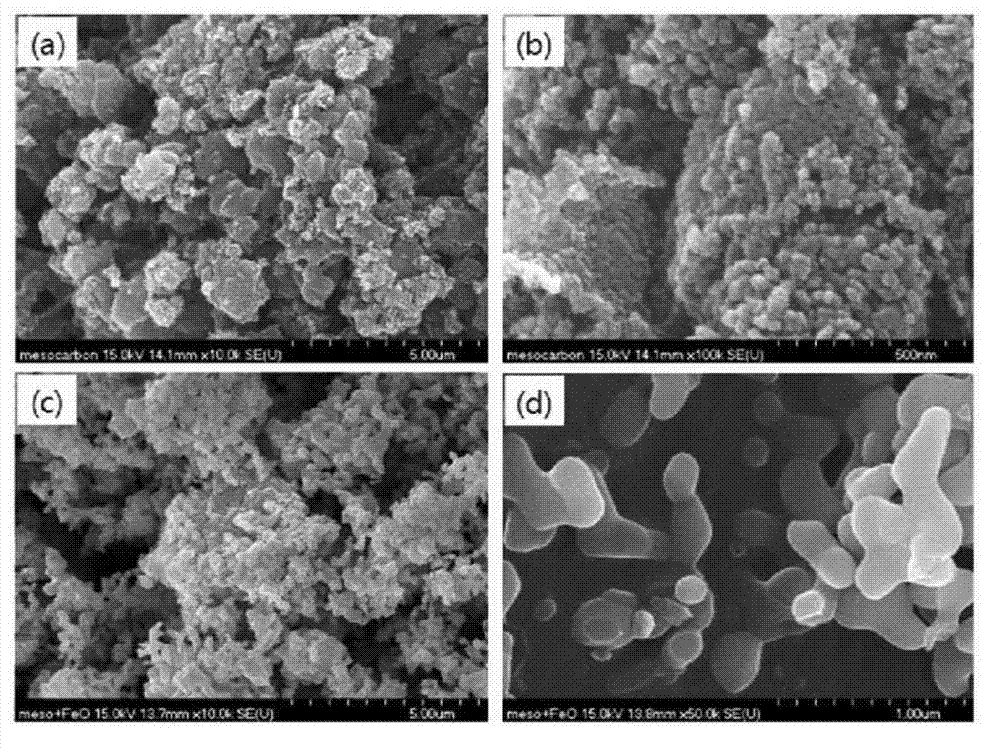

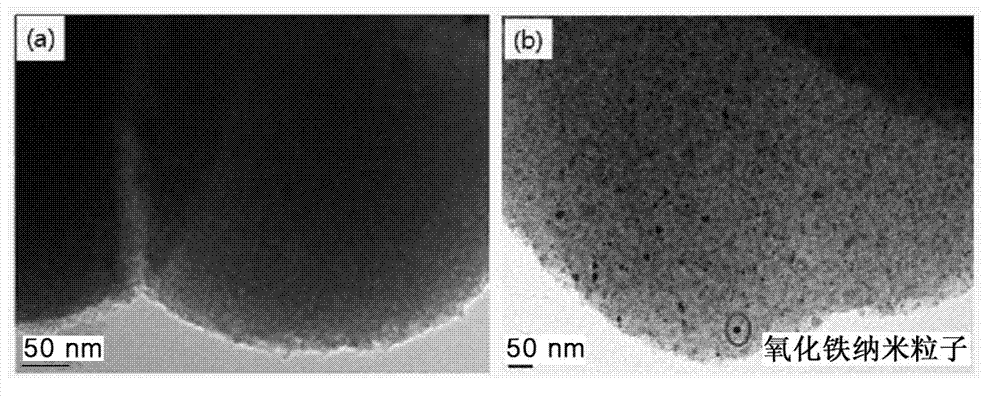

[0036] In addition, the iron oxide nanoparticles purchased from Sigma-Aldrich Corporation had iron oxide nanoparticles (Iron Oxide Nano Particles) with a particle size of 50 nm or less.

[0037] Iron oxide nanoparticles were attached to the surface of the prepared mesoporous carbon by an impregnation method.

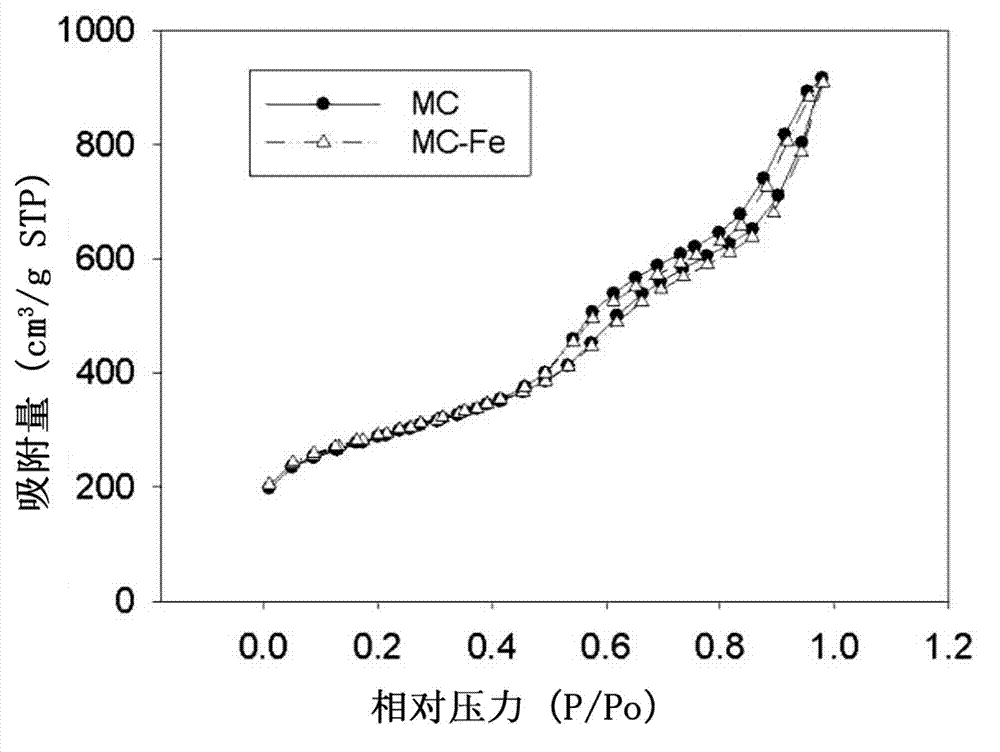

[0038] A Sonicator is used to uniformly disperse the iron oxide nanoparticles on the surface of the mesoporous carbon to reduce the aggregation of the nanoparticles and the phenomenon that the pores of the carrier are blocked by the nanoparticles. By repeating this process, iron oxide nanoparticles are efficiently attached. After drying at 100°C, it was calcined at 900°C under nitrogen.

experiment example

[0040] 1) The reaction of mesoporous carbon adsorption to remove natural organic matter

[0041] For the evaluation of adsorption experiments, natural organic matter was selected as the experimental object. This is because natural organic matter is composed of molecules of different sizes (1 to 1,000,000 Daltons), and iron oxide nanoparticles also have adsorption capacity in addition to mesoporous carbon. For performance comparison, a granular activated carbon (GAC) material representative of water treatment processes was selected as a control group. Natural organic matter (IHSS (International Humic Substance Society), Suwannee River) was put into 50 ml of a solution having an initial concentration of 10 mg / l, and 10 mg of each adsorbent was put into a reactor, and the adsorption test was performed in a batch manner. The pH value of the solution was fixed at 7, and the stirring was continued at a speed of 200 rpm at 25°C. The solution is sampled in order to analyze the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com