Granular quicklime fixed bed dehydration and deodorization system and operation method thereof

A technology of quicklime and fixed bed, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve the problems of inability to provide aerobic biological reactions, dehydration and deodorization, extensive temperature control methods, and poor temperature control effects To achieve the maximum utilization of resources, improve the effect of combined use, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

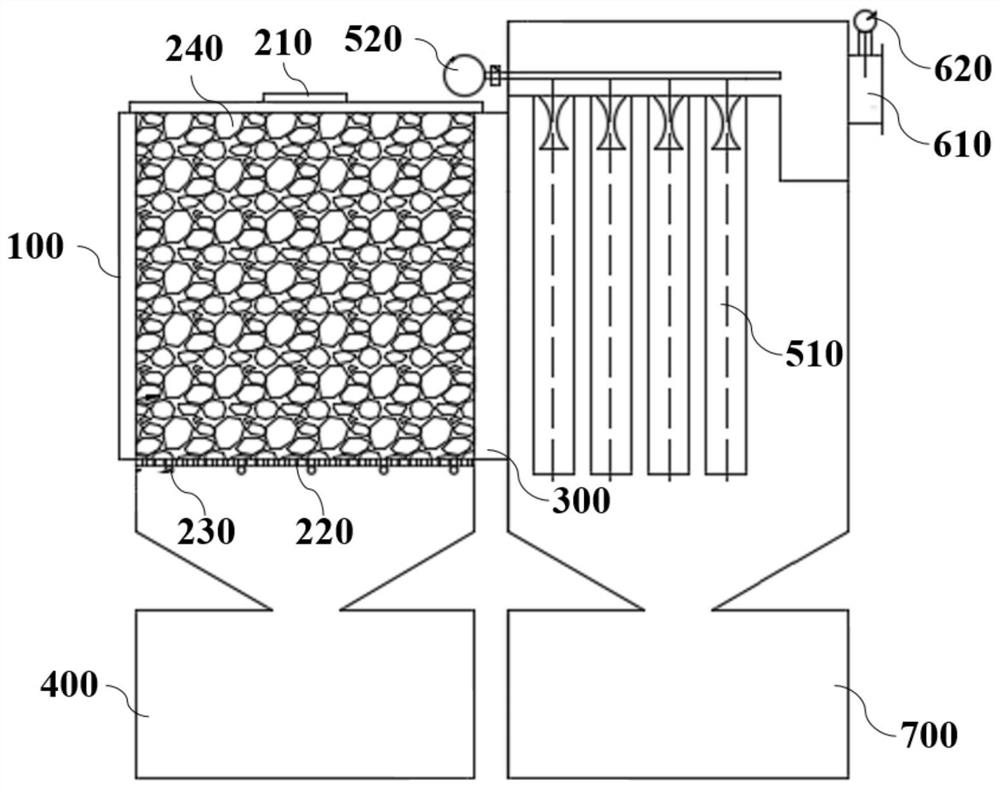

Embodiment 1

[0066] In actual use, the present invention needs to be used in combination with an external material reaction system, and the external material reaction system is generally an aerobic composting reactor. The aerobic composting reactor is provided with a heat exchanger, and the composting temperature of the aerobic composting reactor is controlled at about 40°C. The circulating air transported to the aerobic composting reactor in the present invention takes the water vapor, ammonia, carbon dioxide and other substances produced by the compost out of the aerobic composting reactor, enters the lye absorption tower, and removes ammonia and vulcanization through the lye absorption tower Hydrogen, carbon dioxide and other gases and part of the water vapor, and then use the quicklime fixed bed to remove the remaining moisture in the circulating air and increase the temperature of the circulating air, so that the dry circulating air enters the aerobic composting reactor again to bring ...

Embodiment 2

[0081] The basic content of this embodiment is the same as that of Embodiment 1, except that: in this embodiment, the material quality in the aerobic composting reactor is 10 kg, and the moisture content is 50%. According to the treatment process, the mass of water to be removed from the material is 1kg. Maintain the temperature of the aerobic composting reactor at 40°C, then the outlet air temperature T of the aerobic composting reactor 1 = 40°C. The volume of air required to remove 1kg of water is 20m 3 , the air density is 1.29kg / m 3 ,but:

[0082]

[0083] When the detection temperature T 3 = At 42°C, T 4 =40.5°C, adjust the speed of the metering pump so that the total mass of circulating water flowing through the circulating water heat exchange module m 水 =1139.33kg. Through the precise temperature control in this embodiment, the temperature of the composting reactor can be maintained at about 40° C., providing a good composting reaction environment. After 7 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com