Greasy filth treatment process

A treatment process and oil sludge technology, applied in sludge treatment, water/sludge/sewage treatment, petroleum industry, etc., can solve the problems of waste of limited resources, secondary pollution, high cost of sludge concentration and incineration process, and realize Efficiency and effect, the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further set forth below in conjunction with embodiment. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

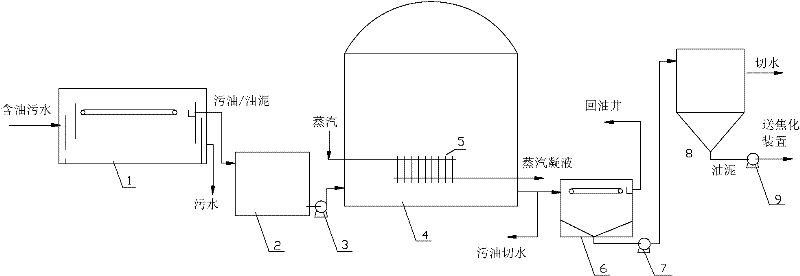

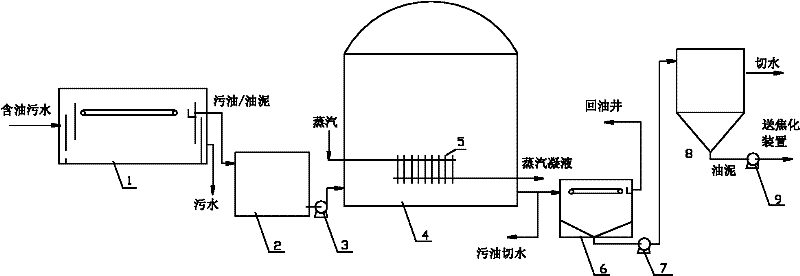

[0036] Such as figure 1 As shown, the present invention is illustrated by taking the oil sludge treatment engineering example of the sewage treatment plant of an oil refinery as an example. Refinery 350m 3 / h The oily sewage first enters the grid well, and the floating and larger suspended matter are intercepted by the thick and thin grid. The oil separation system 1 is composed of an advection type oil separation tank and a sloping plate type oil separation tank connected in series. The water from the grid well first flows into the advection grease trap, and the oily sewage flows in from one end of the advection grease trap, and flows through the pool at a relatively small horizontal velocity (2-5mm / s). During the flow, the density Oil partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com