Intelligent manufacturing technique for printed circuit board

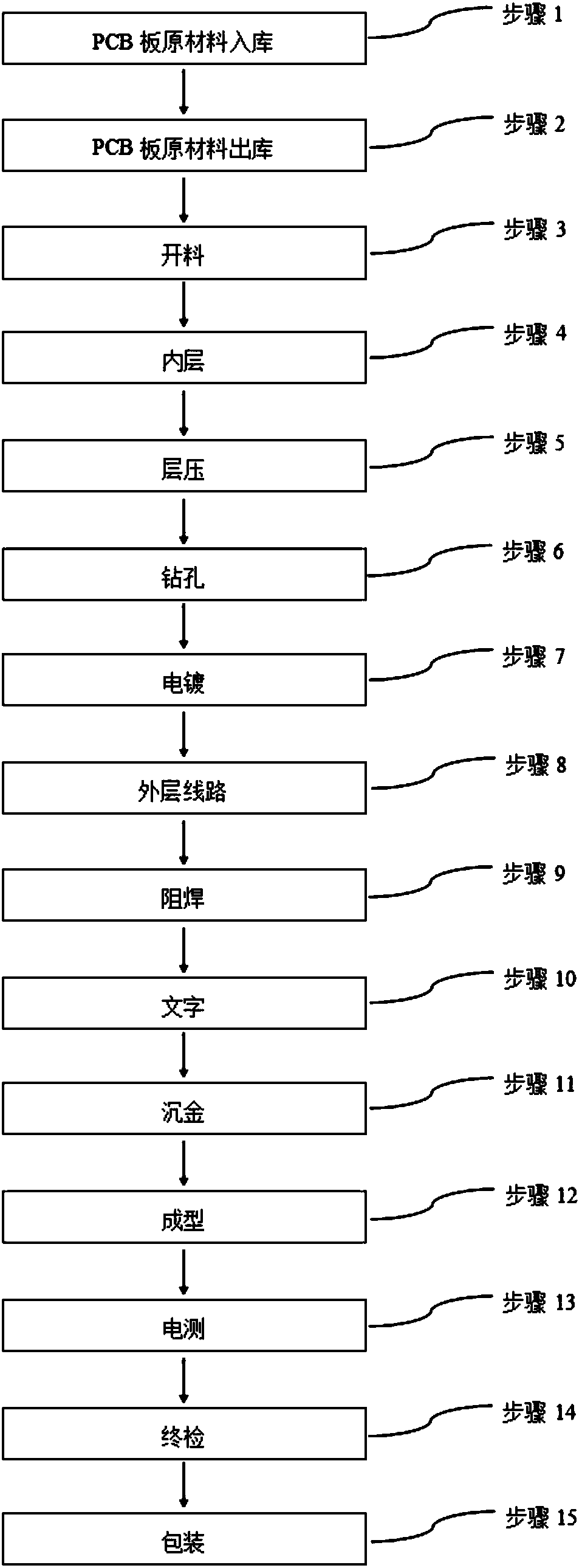

A printed circuit board, intelligent manufacturing technology, applied in the direction of printed circuit manufacturing, printed circuit, program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A model order information: where 1PNL=4SET=8PCS, a PCB board raw material can be opened 4PNL.

[0082] (1) Storage of PCB board raw materials:

[0083] According to the delivery volume of A-type orders received by the marketing department, the ERP system automatically counts 25 required A-type PCB board raw materials, and forms a form and sends them to the purchasing department. After checking, the purchasing department purchases A-type PCB boards as needed. raw materials. A-type PCB board raw materials are shipped by suppliers to the PCB raw material inspection area of the factory. The intelligent storage system automatically detects the quality of A-type PCB board raw materials. The purchased A-type PCB raw materials are stored on three-dimensional shelves according to the number required by the intelligent storage system, and the production information of the A-type PCB raw materials stored in the ERP system is input into the intelligent storage system; unqualifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com