Work-piece cutting and cooling system

A cooling system and workpiece technology, which is applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of reducing the working efficiency of the aluminum strip production system, increasing the manufacturing cost of aluminum strips, and affecting continuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

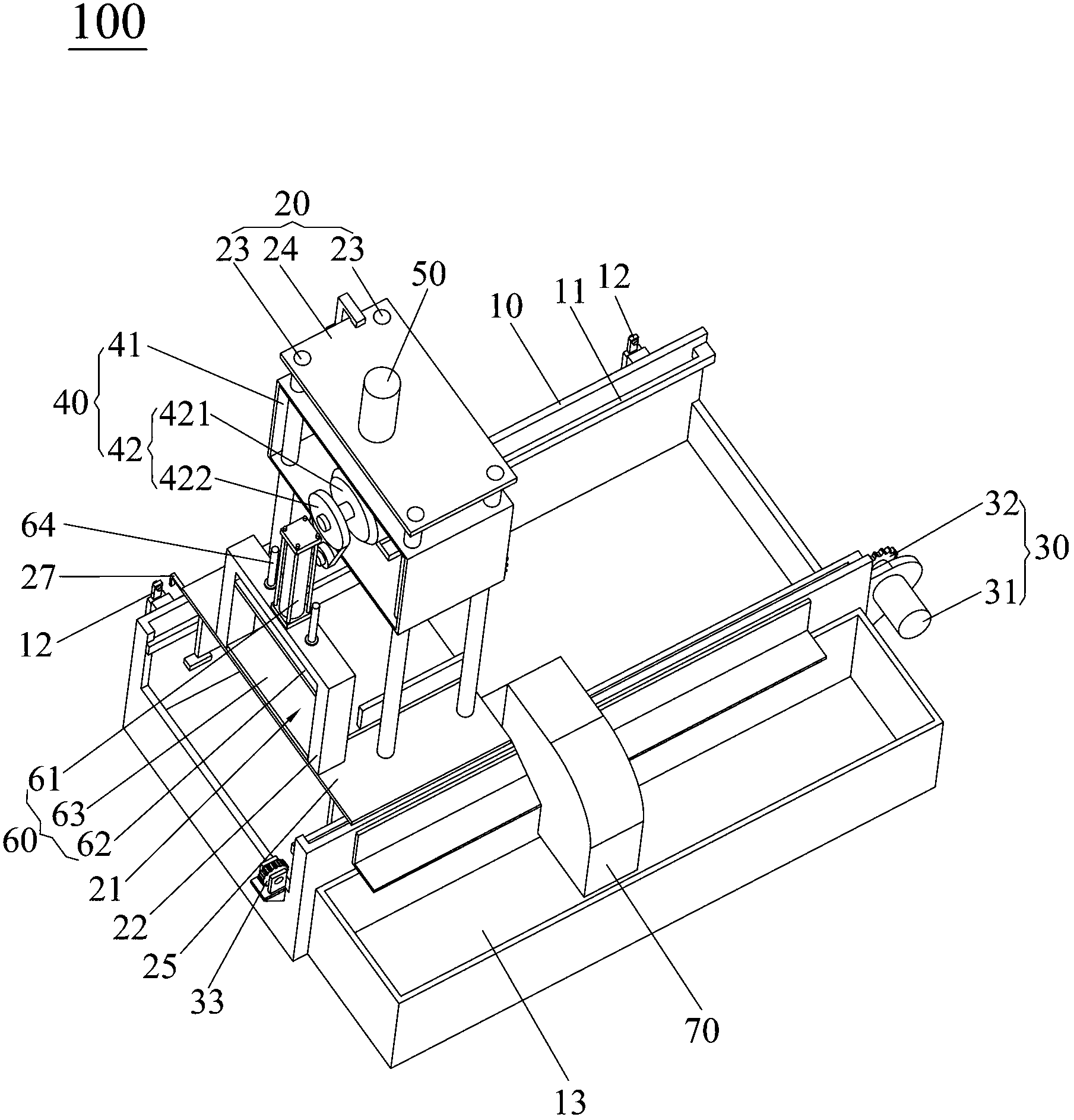

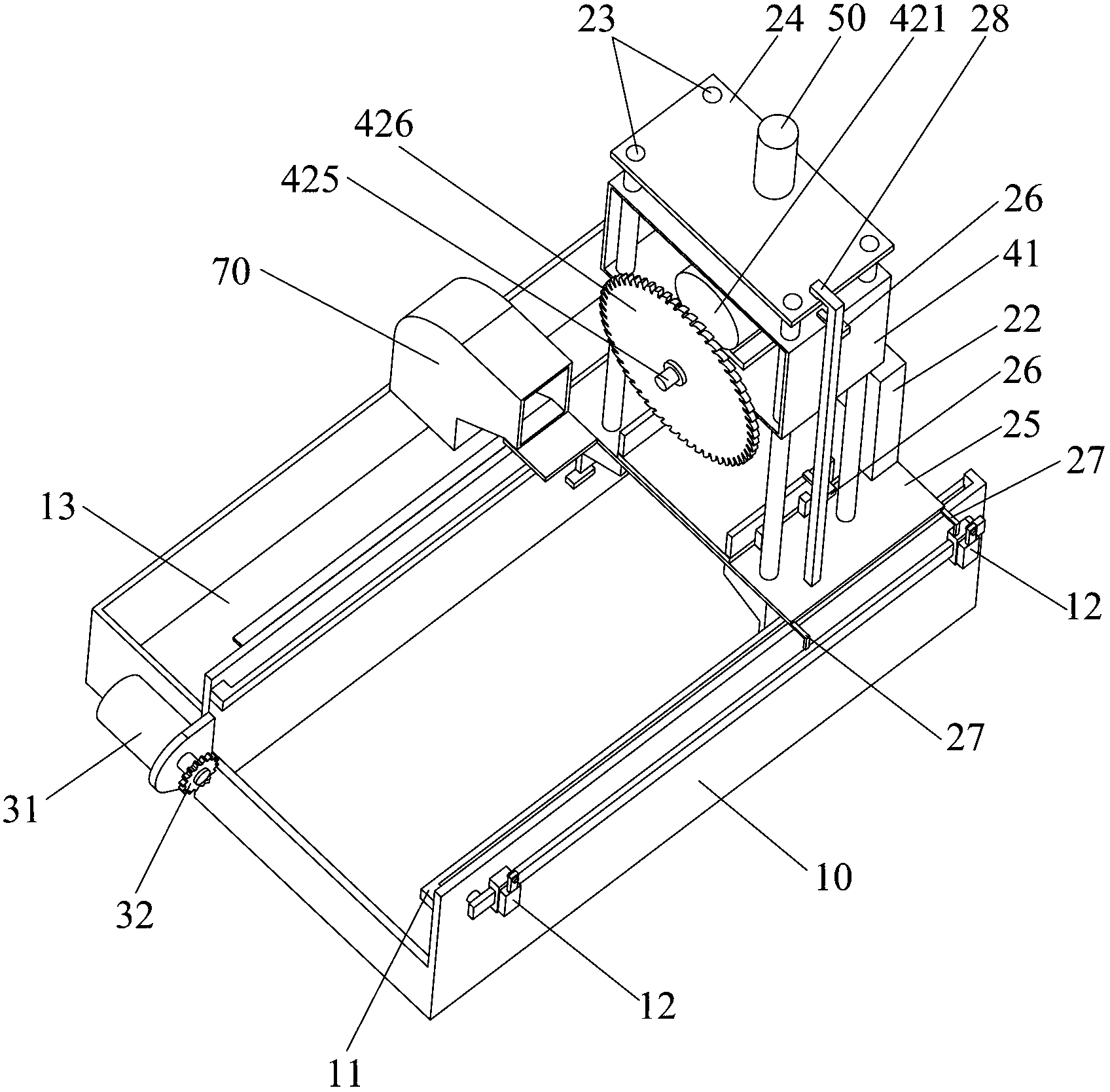

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

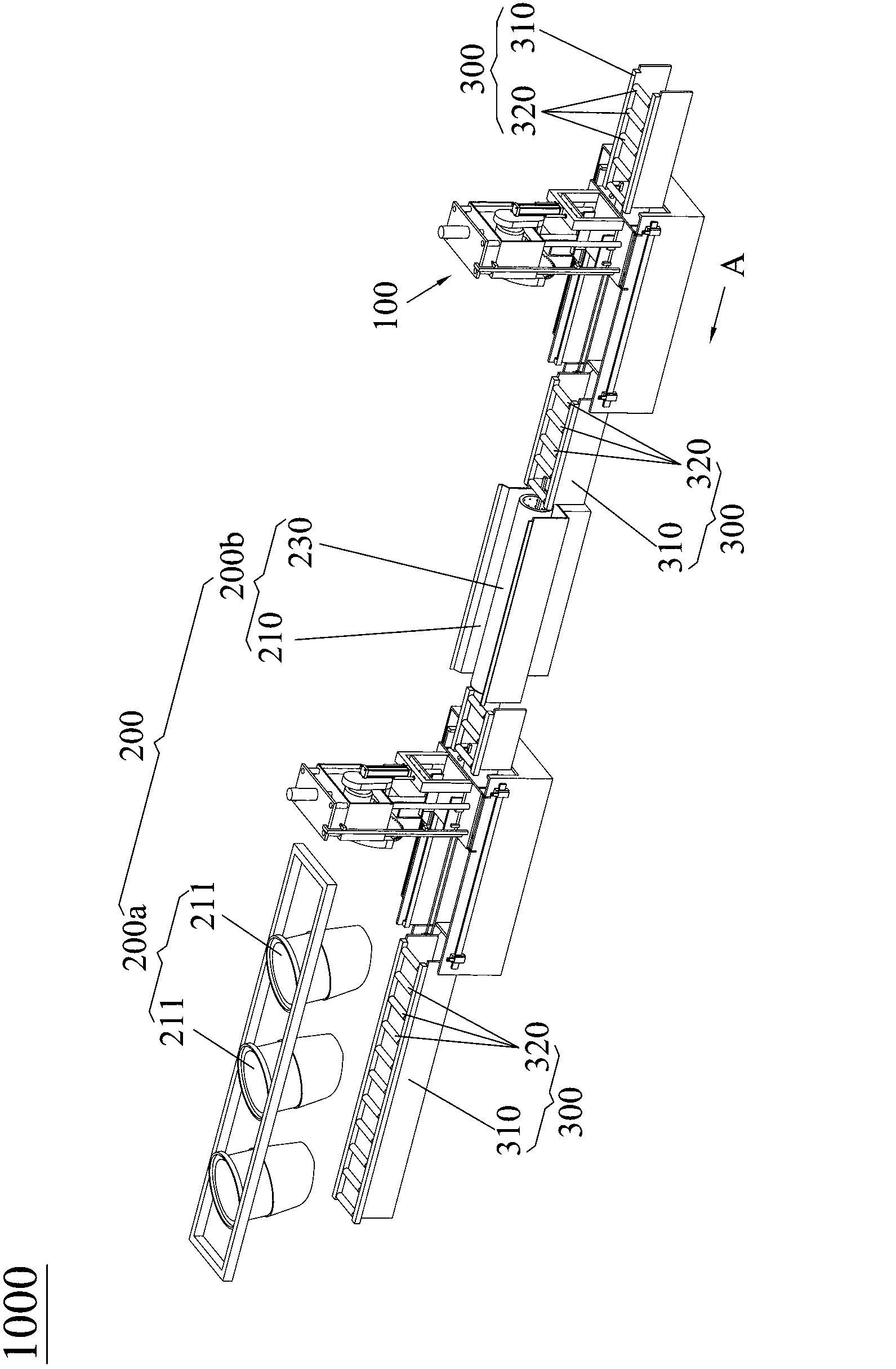

[0027] see Figure 1 to Figure 4 , the workpiece cutting cooling system 1000 of the present invention is electrically connected with the controller, the workpiece cutting cooling system 1000 is arranged on the production line 300 and cuts and cools the workpieces conveyed by the production line 300, and the production line 300 has a track 310 pivotally connected to the track The rolling element 320 on the track 310 and drives the workpiece to be transported, and the driving assembly (not shown in the figure) arranged on the track 310 and driving the rolling element 320 to rotate.

[0028]The workpiece cutting cooling system 1000 of the present invention includes a workpiece cutting device 100 for cutting workpieces conveyed by the production line 300 into workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com