Aluminum material cutting device for hardware machining

A technology for cutting devices and aluminum materials, applied in the direction of shearing devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of slow cutting speed, high production cost, and the inability to adjust the cutting length of aluminum materials, etc., and achieve fast cutting speed , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

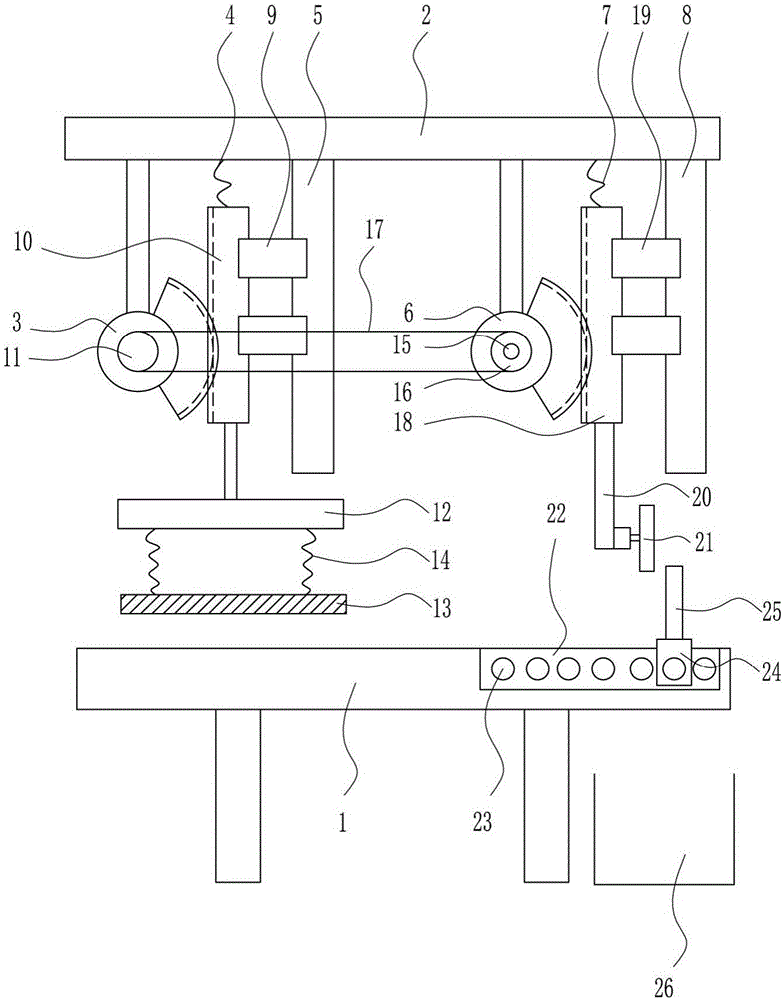

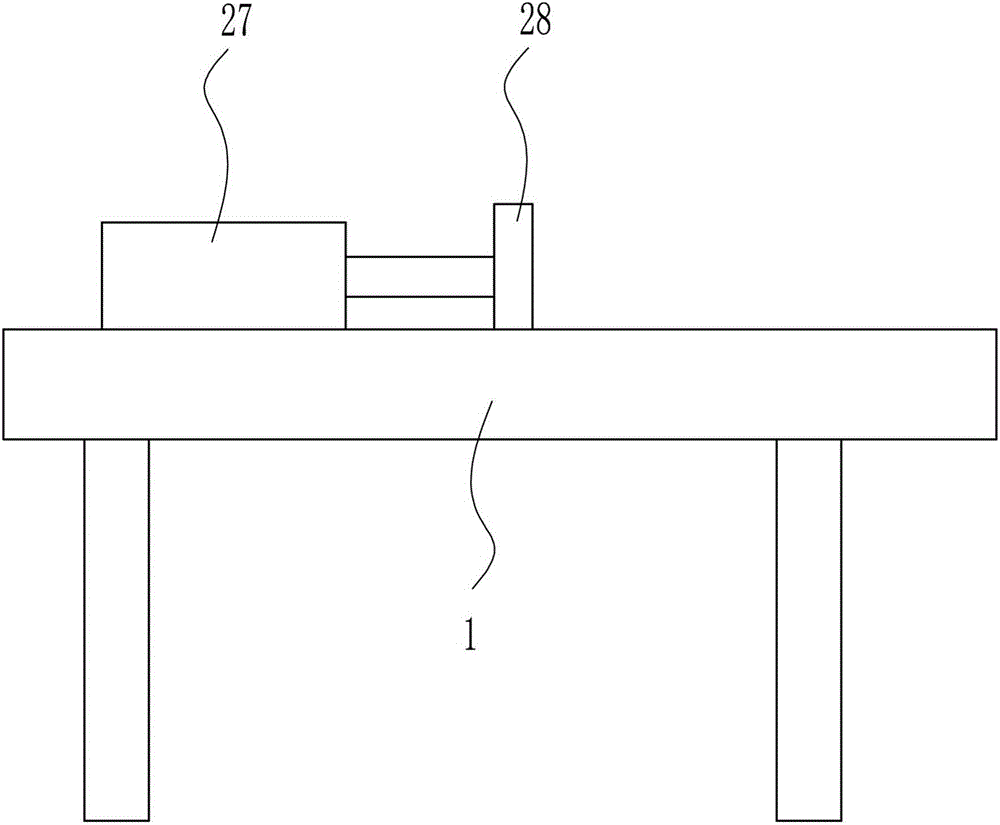

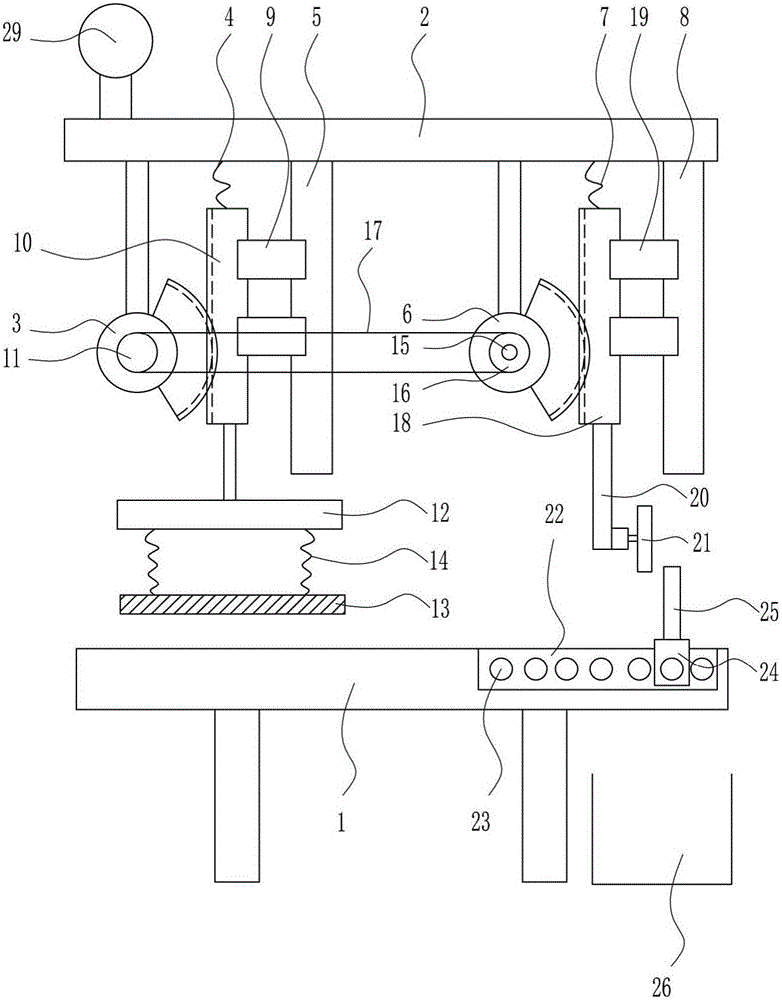

[0028] An aluminum material cutting device for metal processing, such as Figure 1-4 As shown, it includes workbench 1, top plate 2, first sector gear 3, first spring 4, first slide rail 5, second sector gear 6, second spring 7, second slide rail 8, first slider 9. The first rack 10, the first pulley 11, the fixed plate 12, the rubber plate 13, the third spring 14, the motor 15, the second pulley 16, the flat belt 17, the second rack 18, the second slider 19, Strut 20, cutting machine 21, the 3rd slide rail 22, the 3rd slide block 24, baffle plate 25, collection box 26, cylinder 27 and push plate 28, be provided with top plate 2 directly above workbench 1, top plate 2 bottom is from left To the right, the first sector gear 3, the first spring 4, the first slide rail 5, the second sector gear 6, the second spring 7 and the second slide rail 8 are arranged successively, and the first slide rail 5 is slidably connected with The first slider 9, the left end of the first slider 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com