Copper foil plate shearing machine for bimetallic material plate

A material plate and bimetallic technology, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of inability to adjust the cutting length of copper foil conveniently and stably, inability to classify and recycle residual materials and waste slag, and achieve convenience The effect of stabilizing the cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

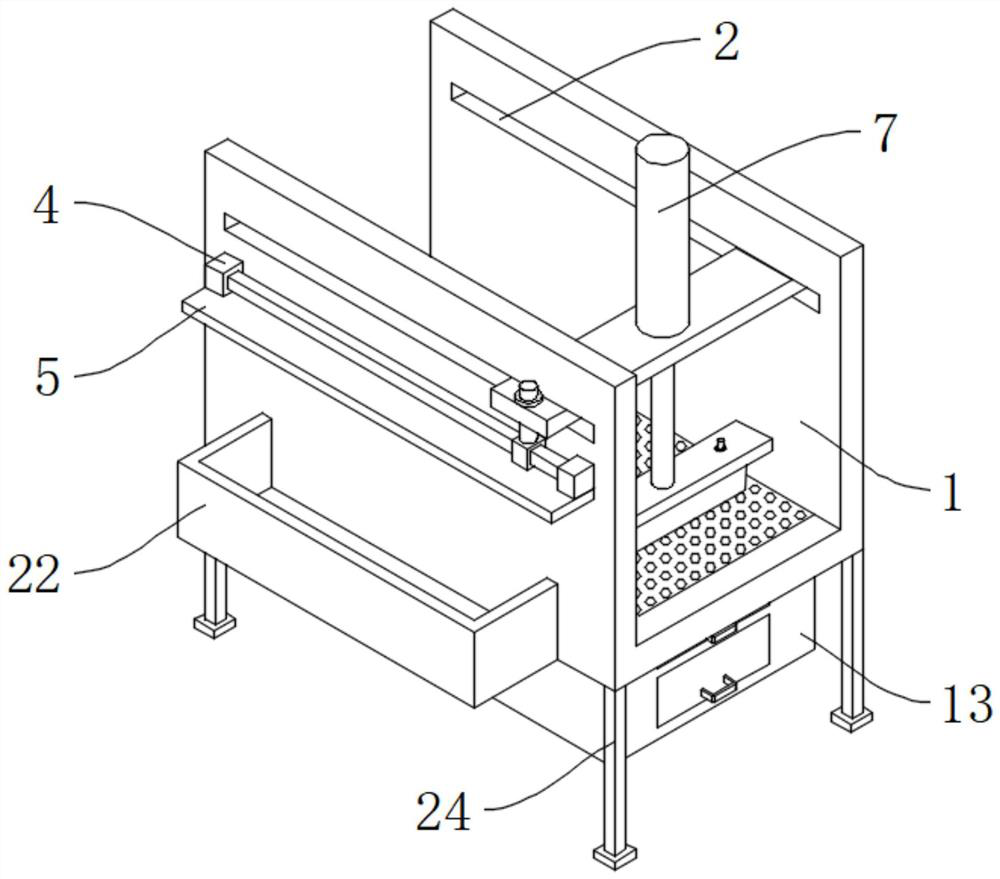

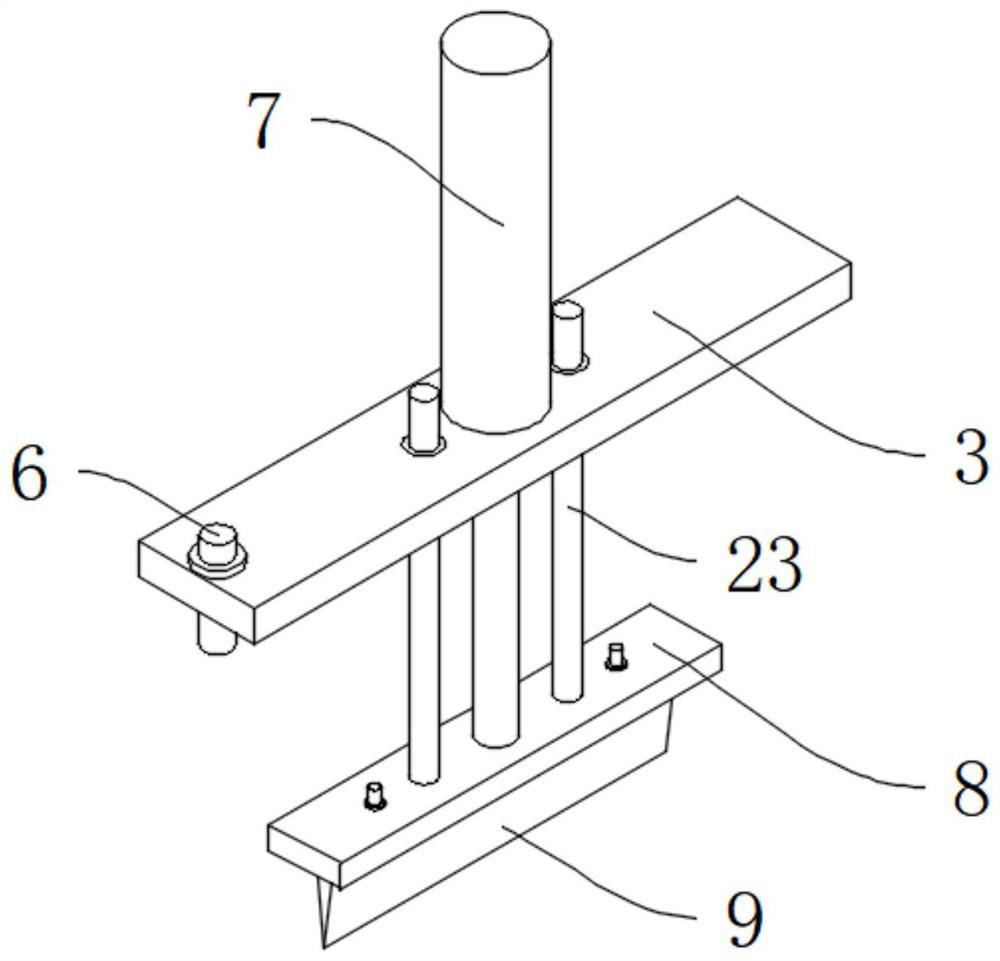

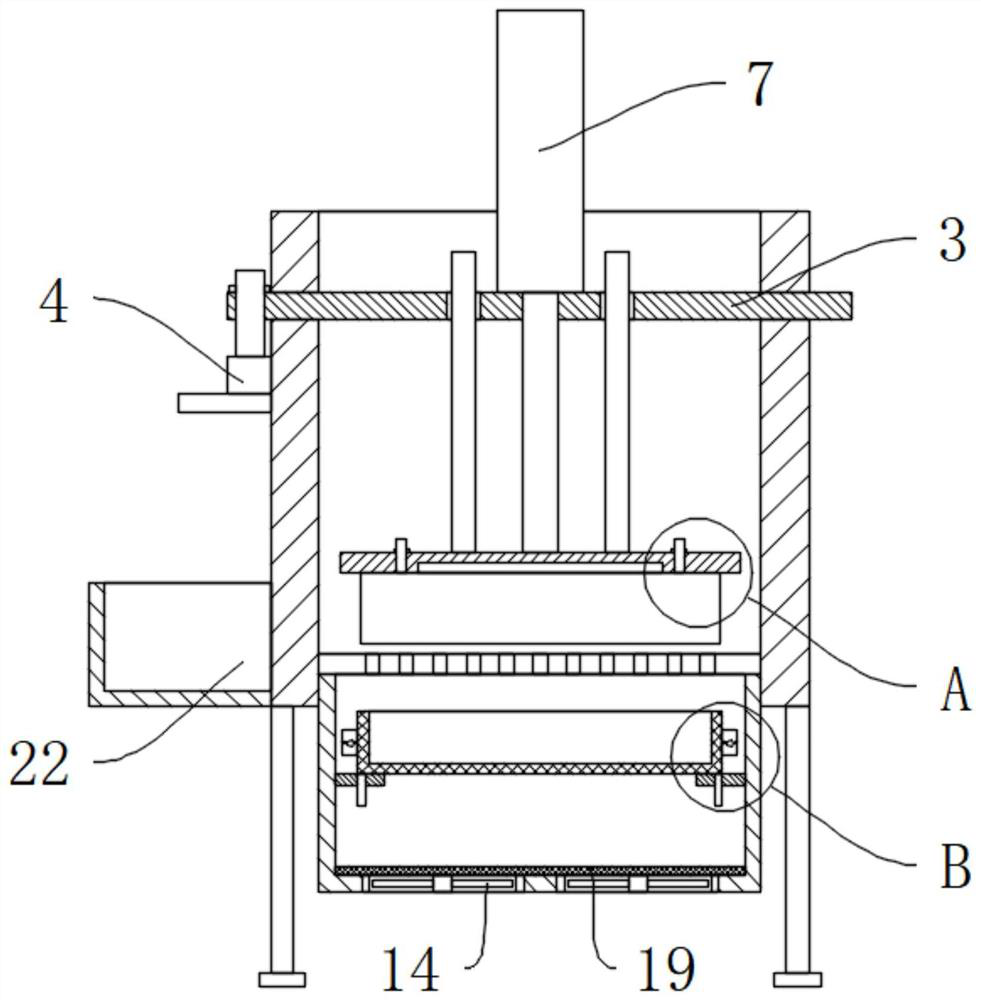

[0027] In order to be able to adjust the cutting length of copper foil conveniently and stably, such as figure 1 and figure 2 , a copper foil shearing machine for bimetal material plates, comprising: a mounting frame 1, the bottom of the mounting frame 1 is welded with four support legs 24 in a rectangular array, and the outer wall of one side of the mounting frame 1 is installed with a plurality of bolts for storing The box 22 can store spare tools in the storage box 22. The shearing plate assembly is installed on the inside of the mounting frame 1. The shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com