Pipe cutting system

A cutting system and pipe fitting technology, applied in the field of pipe fitting processing, can solve the problems of waste of manpower, inability to meet production, low production efficiency, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

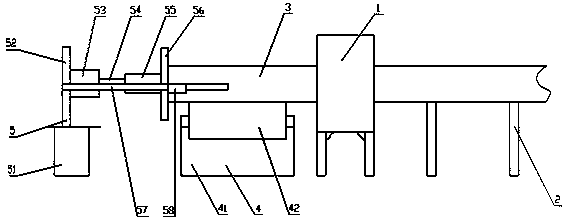

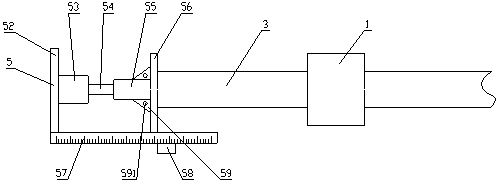

[0028] This embodiment provides a pipe cutting system, such as figure 1 and figure 2 As shown, the pipe cutting system includes a cutting machine 1 for cutting a pipe 3, a delivery support 2 for conveying the pipe 3, a receiving device 4 for receiving the cut pipe 3, and a cutting length for adjusting the pipe 3 The length adjustment structure 5.

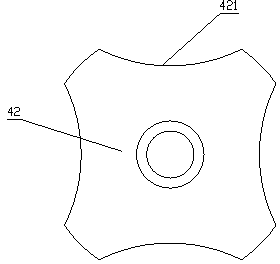

[0029] Wherein, the access device 4 includes an access bracket 41 and a rotating member 42 rotatably installed on the access bracket 41, such as image 3 As shown, the rotating member 42 is provided with four grooves 421 adapted to the outer diameter of the pipe member 3, and the four grooves 421 are evenly distributed along the circumferential direction. Preferably, the rotating member 42 is driven to rotate by a stepping motor. The cut pipe fitting 3 can be accessed through the groove 421, the rotating part 42 is rotated 90 degrees by the stepping motor, the cut pipe fitting 3 falls, and another groove 421 continues to receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com