Cutting device for log machining

A cutting device and log technology, which is applied to wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve the problems of physical injury of workers, inability to cut to fixed lengths, and no dust reduction effect, etc., so as to improve cutting efficiency, Ensure stability and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

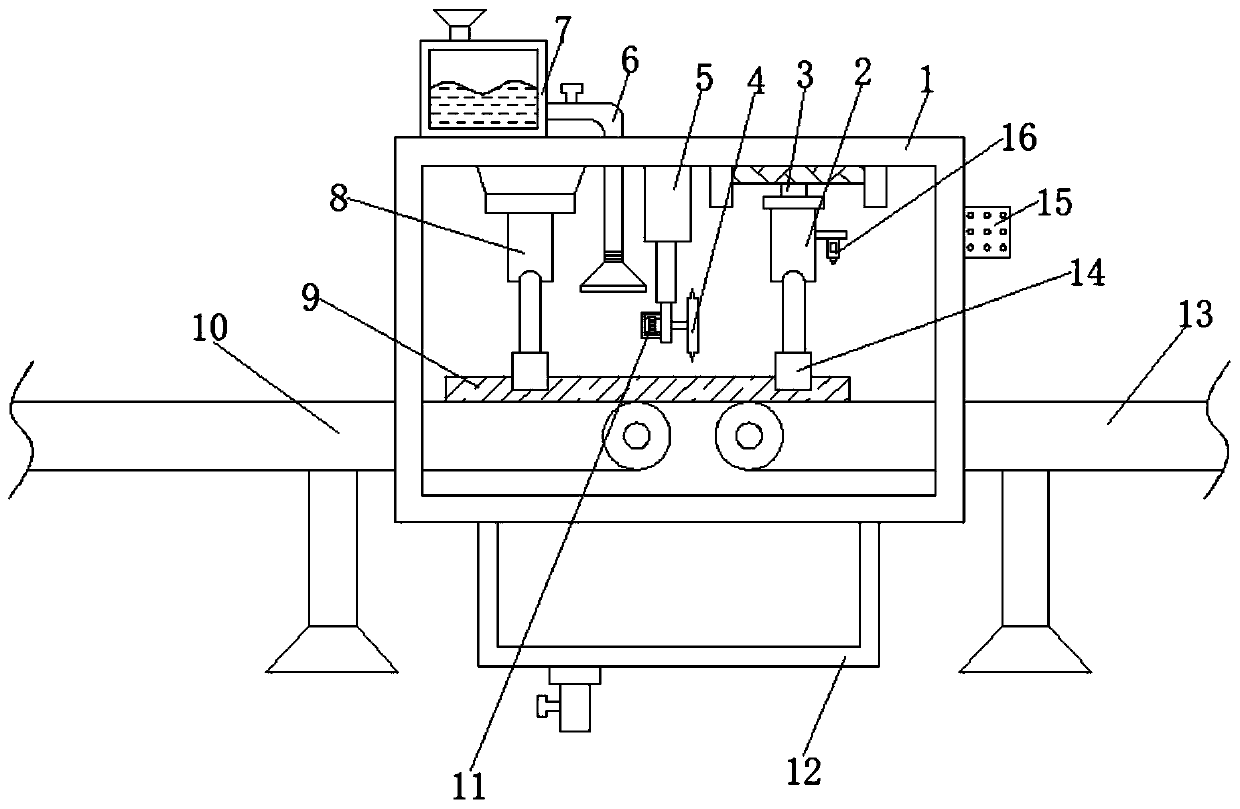

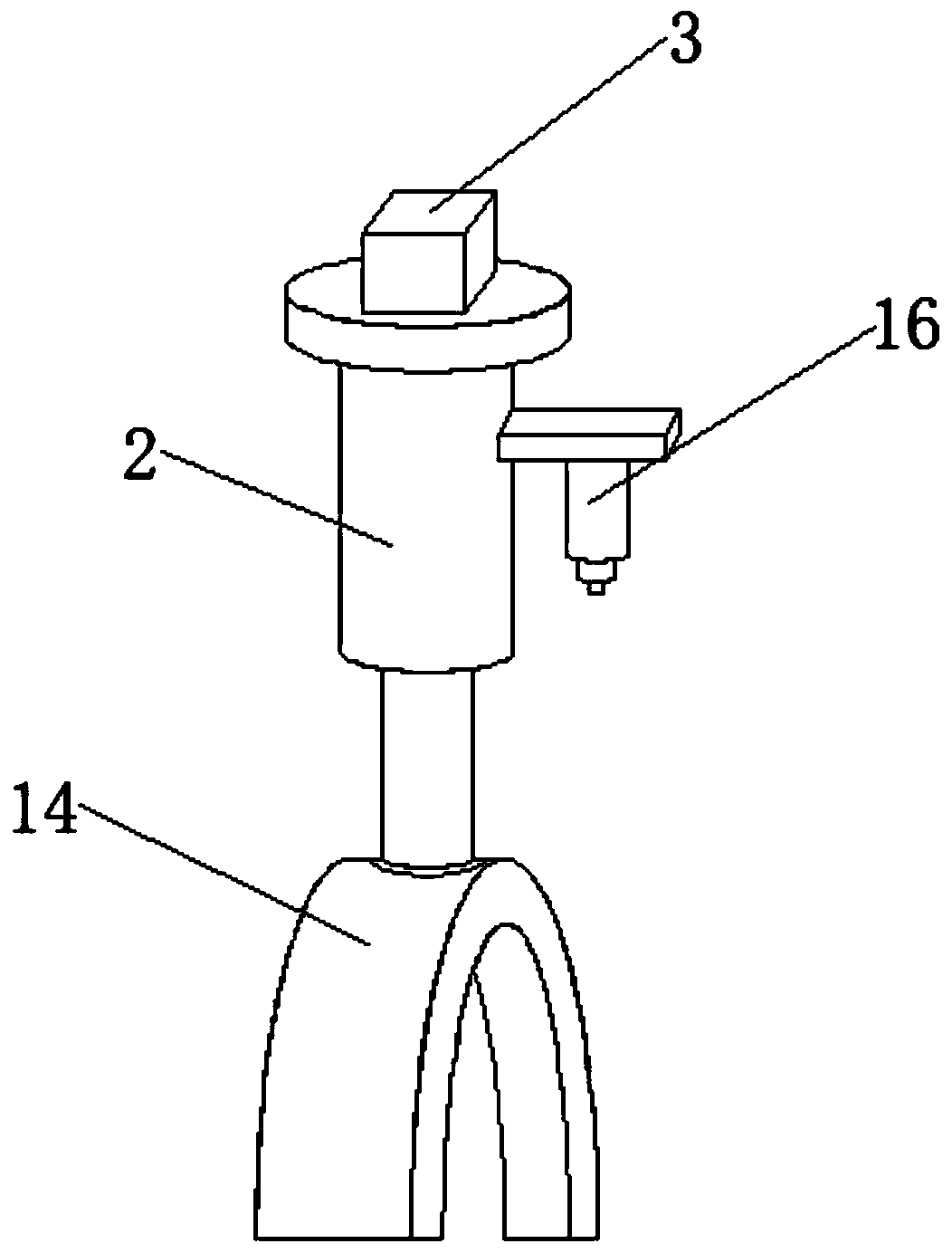

[0026] refer to Figure 1-2 , a cutting device for log processing, including a box body 1, a first conveyor belt 10 and a second conveyor belt 13, the top inner wall of the box body 1 is connected with a second electric push rod 5 by bolts, and one end of the second electric push rod 5 The outer wall is connected with a fixed plate, the outer wall of one side of the fixed plate is connected with the protective shell 11 by bolts, and the inner wall of one side of the protective shell 11 is connected with the motor by bolts, and the outer wall of one end of the output shaft of the motor is welded with the cutting wheel 4, the box body 1 The top outer wall of the tank is connected with a liquid storage tank 7 by bolts, and a connecting pipe 6 is plugged into one side of the liquid storage tank 7, and one end of the connecting pipe 6 extends to the inside of the box body 1, and one end of the connecting pipe 6 is threaded on the outer wall. Atomizing nozzle.

[0027] Wherein, the...

Embodiment 2

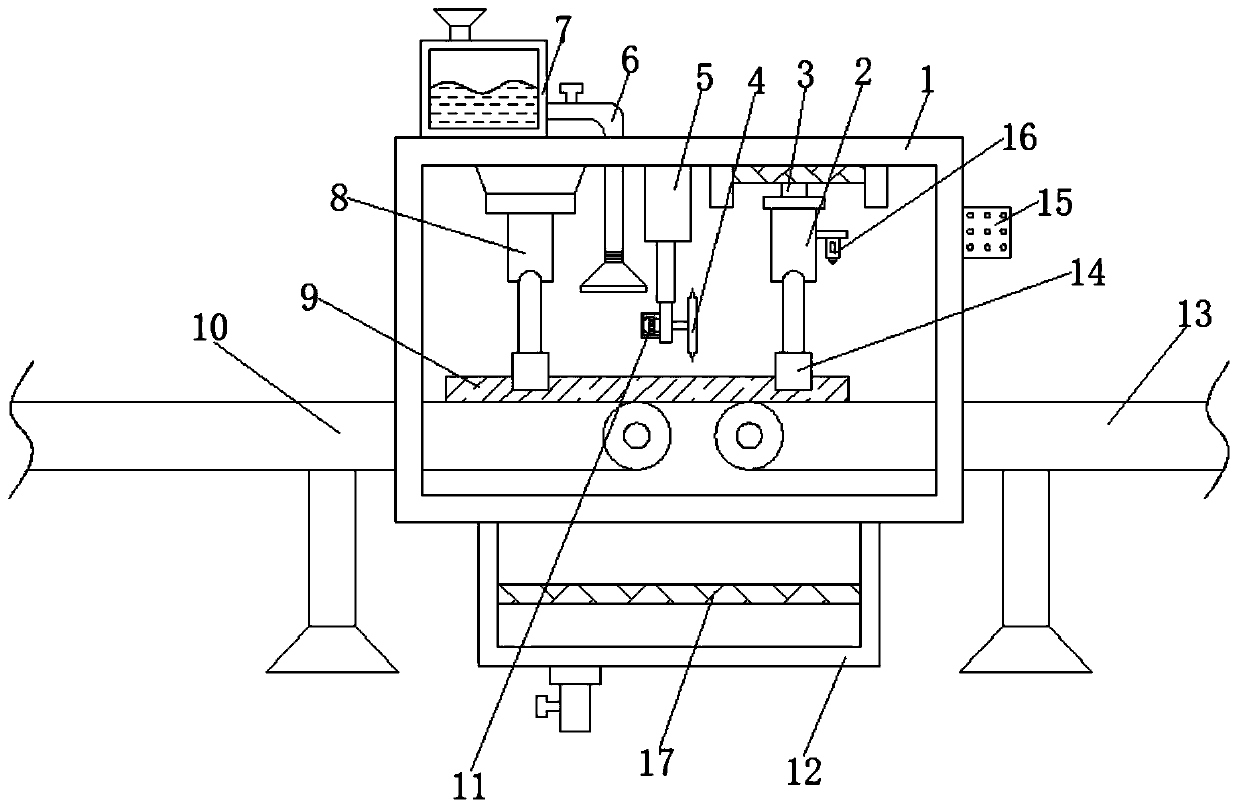

[0030] refer to image 3 , a cutting device for log processing. Compared with Embodiment 1 in this embodiment, the inner walls on both sides of the material storage box 12 are connected with filter screens 17 by bolts.

[0031] Working principle: when in use, the staff places the wood body 9 on the first conveyor belt 10, and with the conveyance of the first conveyor belt 10, when the wood body 9 moves to the right below the infrared sensor 16, the first conveyor belt 10 and the second The conveyor belt 13 stops working, and the first electric push rod 2, the second electric push rod 5 and the third electric push rod 8 start working simultaneously, and the second electric push rod 5 drives the cutting wheel 4 to cut the timber body 9, and the first The electric push rod 2 and the third electric push rod 8 drive the fixing ring 14 to move down and can effectively fix the timber body 9, which ensures the stability of the cutting work and improves the cutting efficiency of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com