Steel pipe cutting and port grinding integrated device for building construction

A technology for building construction and steel pipes, which is applied in the field of steel pipe cutting and port grinding integrated devices for building construction, which can solve problems affecting work progress, easy shaking, and medium pollution, so as to improve work efficiency, firmly fix steel pipes, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

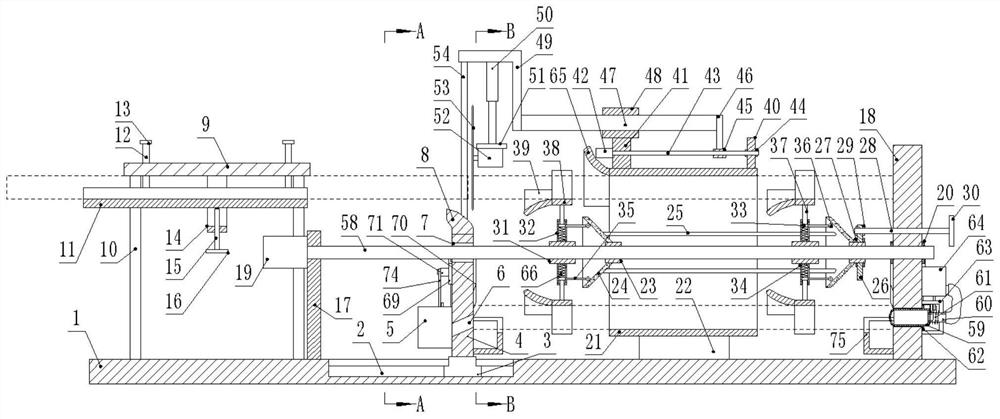

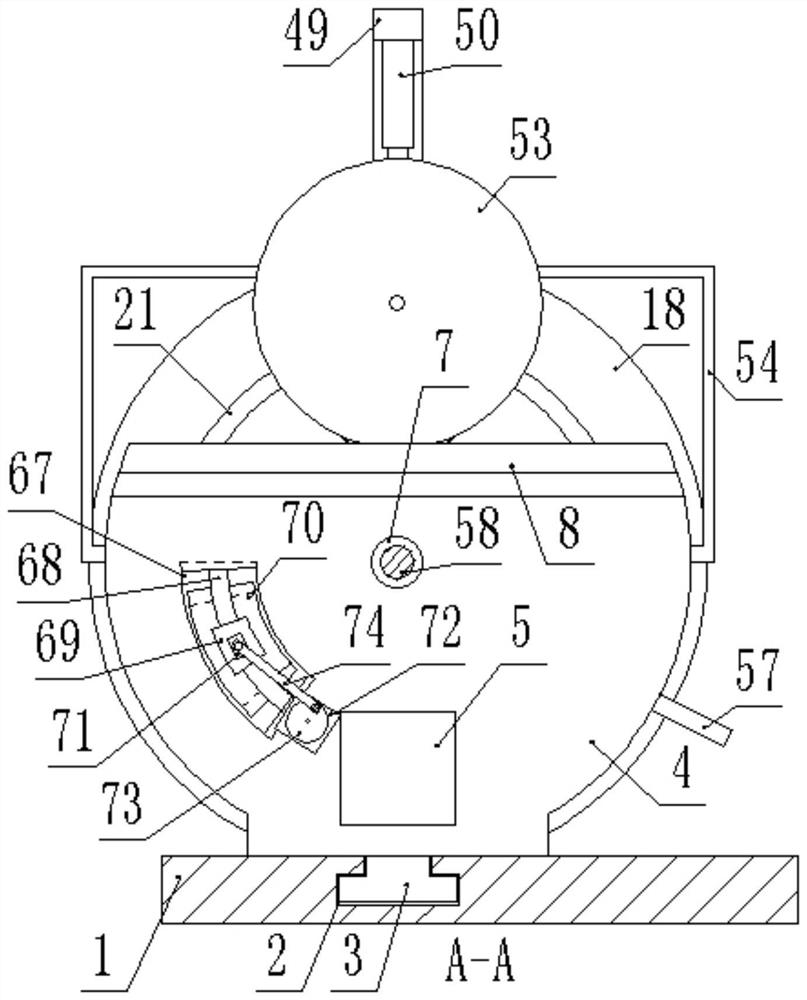

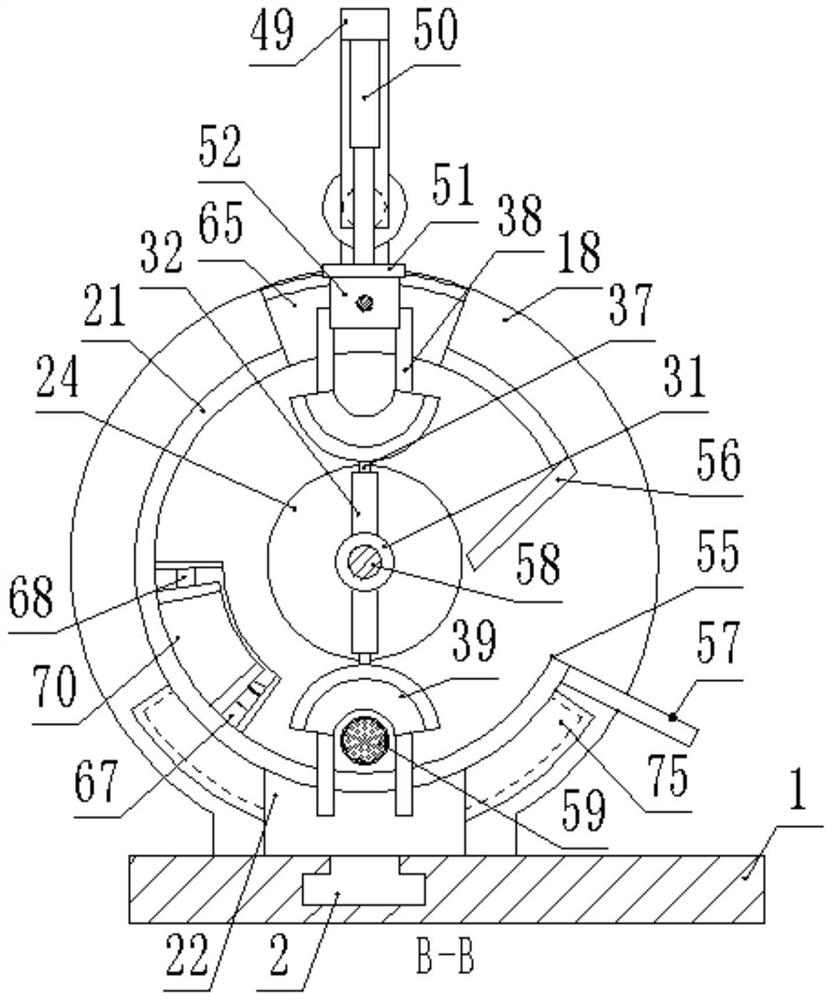

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a steel pipe cutting and port grinding integrated device for building construction, including a horizontal plate 9, is characterized in that: the four corners of the bottom of the horizontal plate 9 are respectively fixed with outriggers 10, and the bottom of the horizontal plate 9 is fixed with U-shaped plate 14, the U-shaped plate 14 passes through an arc-shaped plate 11 transversely, the inner arc surface of the arc-shaped plate 11 is opposite to the bottom surface of the horizontal plate 9, and two ends of the top of the arc-shaped plate 11 are symmetrically fixed respectively. A guide rod 12, the top of the guide rod 12 penetrates the horizontal plate 9 and is fixed with a stopper 13, the contact of the guide rod 12 and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com