Diamond grinding cutter disc and grinding device

A diamond and cutter head technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc., can solve the problems of increasing the diameter of the grinding disc, the difference in line speed, and low efficiency, and achieve good grinding effect , not easy to break, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

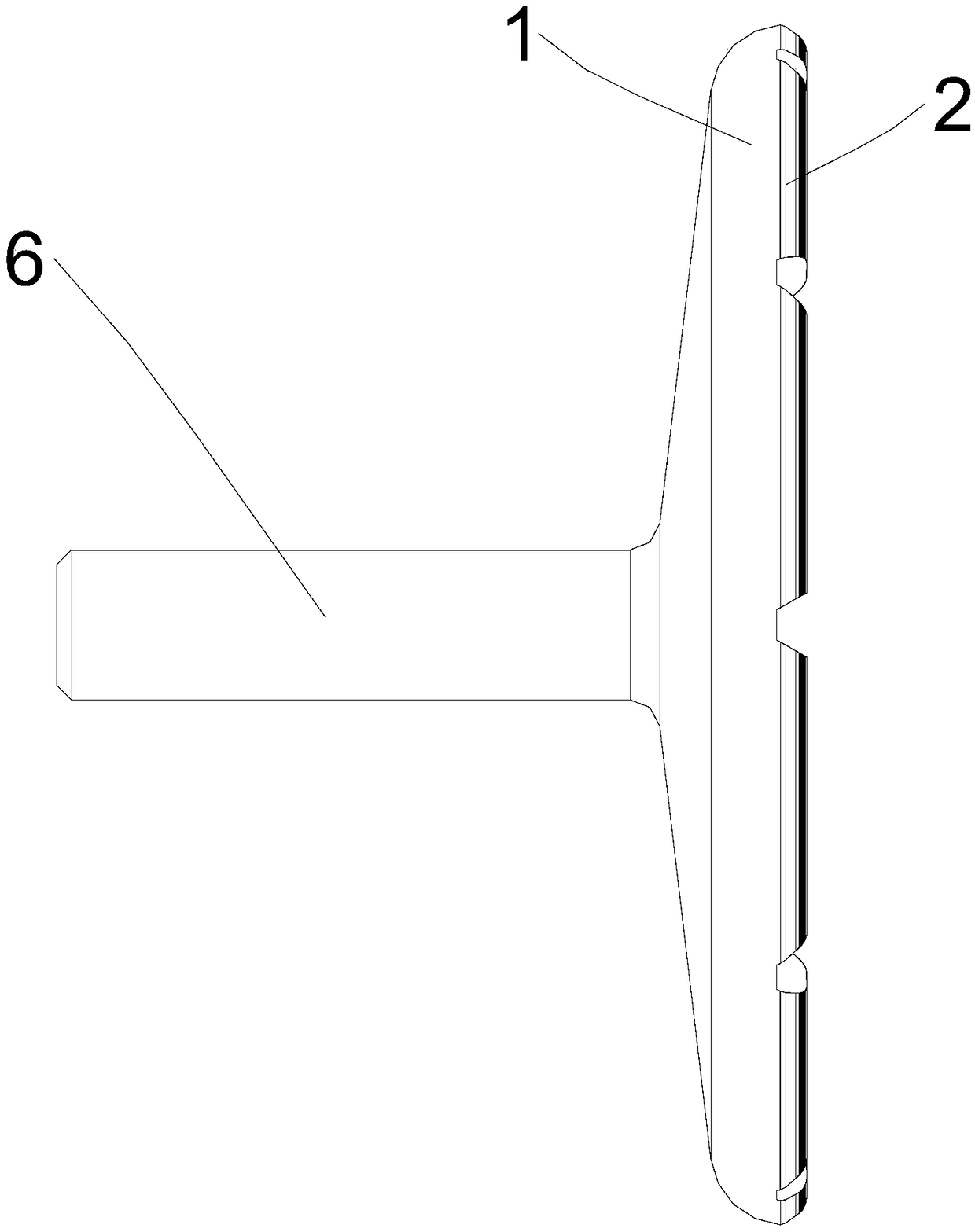

[0080] Such as Figure 10 to Figure 12 As shown, this embodiment provides a kind of grinding equipment, and described grinding equipment comprises the cutter head that has coolant hole as above, described diamond grinding cutter head,

[0081] It also includes a knife handle, which includes a knife handle body 10, one end of the knife handle body 10 is provided with a protrusion 7 matching the coolant hole 5, and surrounding the protrusion 7 is uniformly arranged threaded holes matched one by one to a plurality of said bolt holes;

[0082] The other end of the handle body 10 is provided with a connecting hole 8 for connecting with the main shaft;

[0083] The center of the handle body 10 is provided with a cooling liquid passage 9 passing through the protrusion 7 and the connecting hole 8;

[0084] A circle of protruding positioning rings is provided on the peripheral side of the handle body 10;

[0085] A dynamic balance ring 100 is sheathed on the peripheral side of the h...

Embodiment 2

[0096] Such as Figure 13 to Figure 17 As shown, this embodiment provides a kind of grinding equipment, described grinding equipment comprises the cutterhead with cutterhead handle as above,

[0097] It also includes a knife handle, which includes a knife handle body 10, a wireless transmission receiving device 300, and an ultrasonic transducer;

[0098] The first end of the handle body 10 is provided with a connecting hole for connecting with the spindle of the machine tool; the second end of the handle body 10 is provided with a mounting cavity 110; the peripheral side of the handle body 10 is provided with a circle Protruding locating ring;

[0099] The ultrasonic transducer includes a horn 410 and a piezoelectric vibrator 420 arranged at the first end of the horn 410, and the second end of the horn 410 is installed with the diamond grinding mill through a cutter head connector. Cutter disc; the second end of the horn 410 is also provided with a connecting piece 411, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com