Drying device for printing

A drying device and drying device technology are applied in printing, printing presses, general parts of printing machinery, etc., which can solve the problems of low work efficiency and poor drying effect, save energy, not easy to jam, and enhance drying. dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

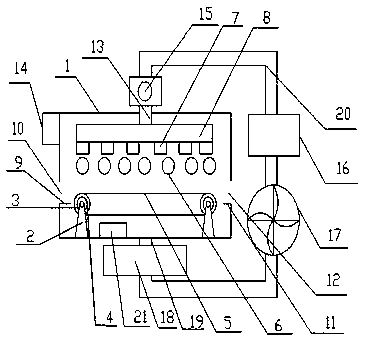

[0015] Such as figure 1 As shown, the present invention provides a drying device for printing, which includes a housing 1, two sets of support bases 2 are provided at the bottom of the inner cavity of the housing 1, and motors 3 are provided on the tops of the two sets of support bases 2 , the output shafts of the two groups of motors 3 are connected with a reel 4, a belt 5 is arranged between the two groups of reels 4, a frequency converter 21 is installed on one side of the support base 2, and the frequency converter 21 and The motors 3 are electrically connected, and the inner cavity of the housing 1 is uniformly provided with infrared heating lamps 6, and the infrared heating lamps 6 are arranged on the top of the belt 5, and the top of the inner cavity of the housing 1 is plugged with Air intake pipe 13, the bottom of the air intake pipe 13 is provided with a shunt pipe 8, the bottom of the shunt pipe 8 is uniformly provided with a drying pipe 7, and the infrared heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com